|

TIGHT OIL BASICS

TIGHT OIL BASICS

Most of us are familiar with tight gas reservoirs – clean,

low porosity sandstones or siltstones that look unattractive

on log analysis, at least by the conventional wisdom of the

1960’s. By the end of the 1970’s, we had overcome these

hang-ups and exploitation in tight sands developed rapidly,

along with the fracturing technology needed to make them

economic.

The same

revolution is occurring in oil exploration. Tight oil or “shale oil”

is the current hot topic. Again, most such plays are siltstones without a lot of clay in the reservoir.

Tight oil is considered to be an

“unconventional” reservoir, requiring horizontal wells and massive

hydraulic fracture jobs to perform economically. Some siltstones are

sufficiently sandy to produce oil in vertical wells, usually after a

decent stimulation. Conventional shale corrected complex lithology

log analysis models are used, even in shaly silts.

Some tight

oil plays fall into the genuine "mature oil shale" category, so a

kerogen correction might also be made over the nearby

source rocks and the reservoir interval. Mature oil shales are

distinguished from

immature oil shale

by the fact that liquid hydrocarbons are present. The immature oil

shale requires an in-situ or surface retort to obtain liquid

hydrocarbons.

Many

siltstones are radioactive because of uranium. It pays to run a

spectral gamma ray log to distinguish between uranium and clay

content.

The Bakken

formation in the Williston Basin of Saskatchewan, Manitoba, and

North Dakota is a classic silt and sandy silt. It is low resistivity

due to high salinity formation water with high irreducible water

saturation (caused by very fine grain size), and the lithology is a

mix of quartz and dolomite (and sometimes calcite). An analogous

resource play is being evaluated in the Paris Basin of France. In

Alberta and Montana, the Bakken equivalent, the Exshaw, and adjacent

formations (Banff / Lodgepole and Big Valley /Three Forks) are

“Tight Oil” prospects, as are the Duvernay, Second White Specks,

Nordegg, and other formerly unattractive low porosity reservoirs.

Each of these

plays has its unique petrophysical problems, so one-size does not

fit all. For example, the Second White Specks is a laminated shaly

sand with fairly good porosity in the sand lenses. The Nordegg may

be pyrobitumen plugged with little room for liquid hydrocarbons.

Beware the "general" solution - even the one described below.

“Tight Oil”

as a descriptive term covers a wide variety of reservoir conditions.

For example, the Nordegg in many places in Alberta is quite porous

and would be permeable if it were not partially or completely

plugged with pyrobitumen. The shaly parts are often described as

bituminous shale. Mineralogy varies from near pure quartz to

dolomite to calcite, with all shades of grey in between. Classical

crossplots to find TOC are meaningless due to these mineral

variations.

Further, classic TOC log analysis methods cannot tell kerogen from

pyrobitumen, nor from ordinary oil and gas for that matter. Ordinary

“TOC scans” often produce silly results unless a full scale

petrophysical analysis calibrated to lab data is also run.

Impossibly

low water saturation on log analysis (equivalent to very high

resistivity) is the clue to the pyrobitumen. Core porosity and

saturation is also a clue, since pyrobitumen is not soluble in

normal solvents, so the core cannot be “cleaned”.

Every tight oil play is different and each needs a different mindset

to understand the available data. Four uniqe examples are shown

below.

EXAMPLES OF DIFFERENT TYPES OF TIGHT OIL PLAYS

EXAMPLES OF DIFFERENT TYPES OF TIGHT OIL PLAYS

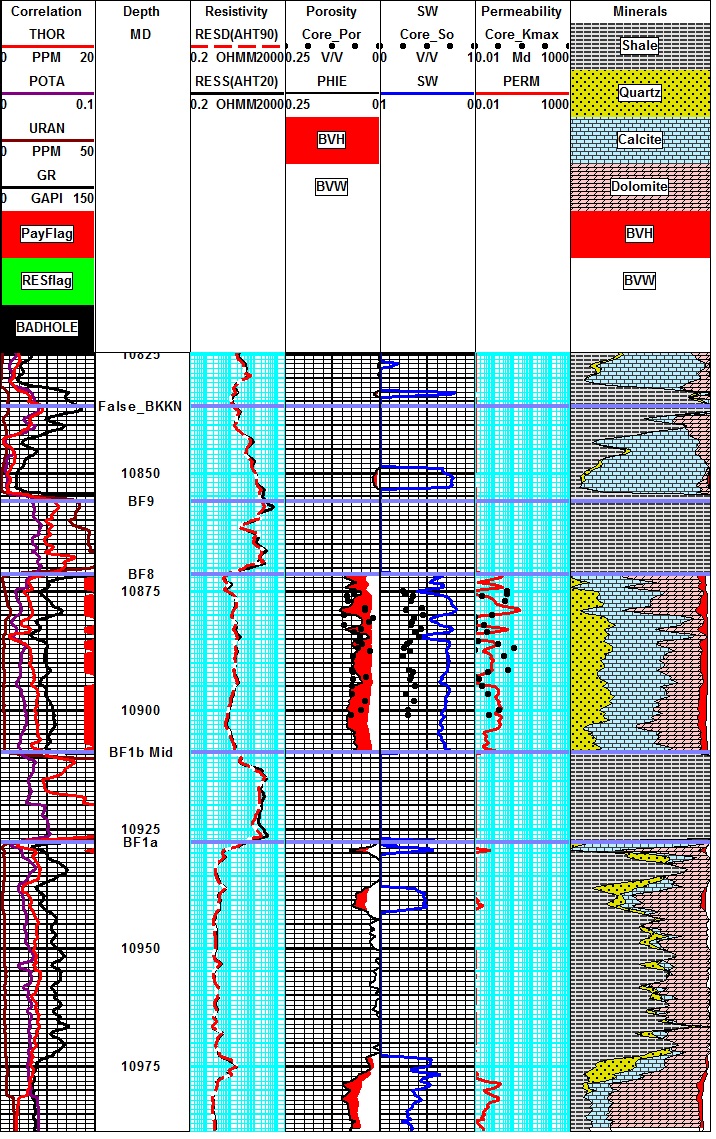

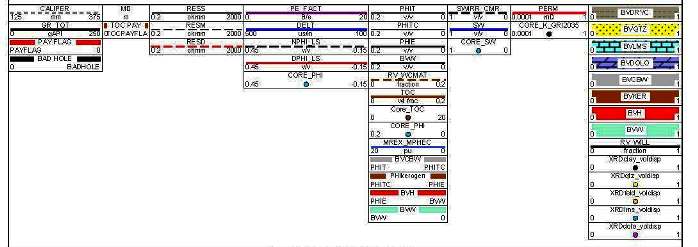

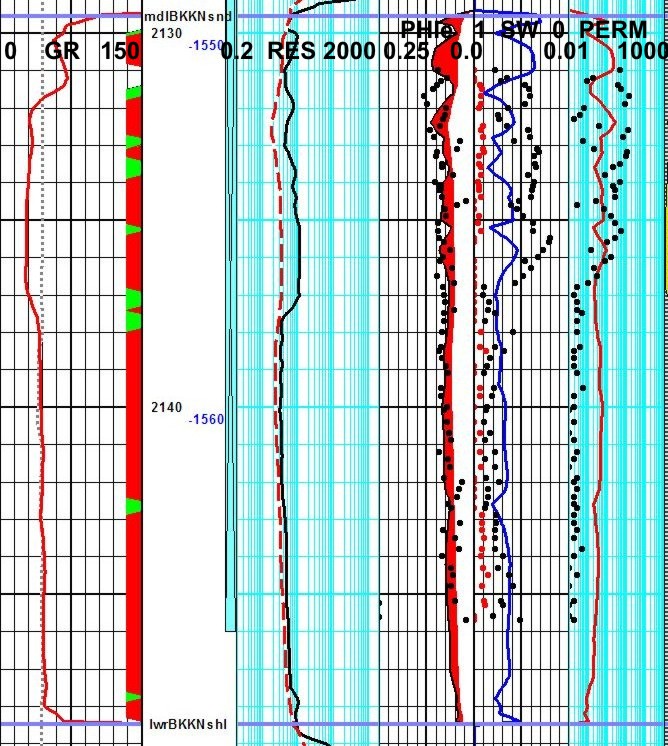

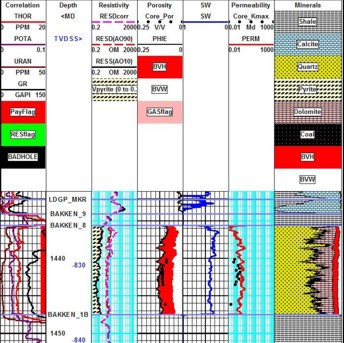

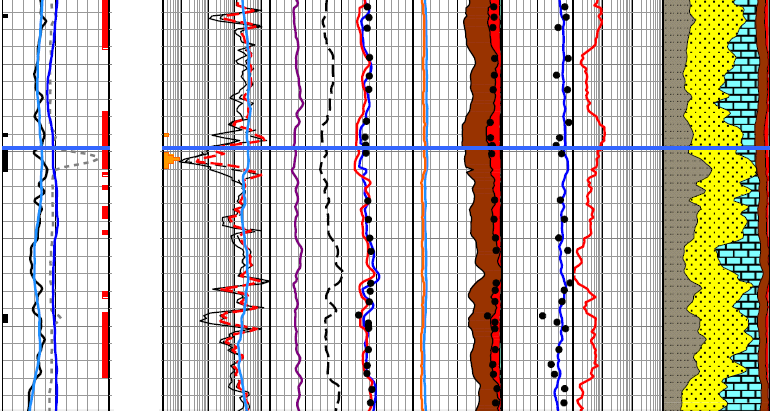

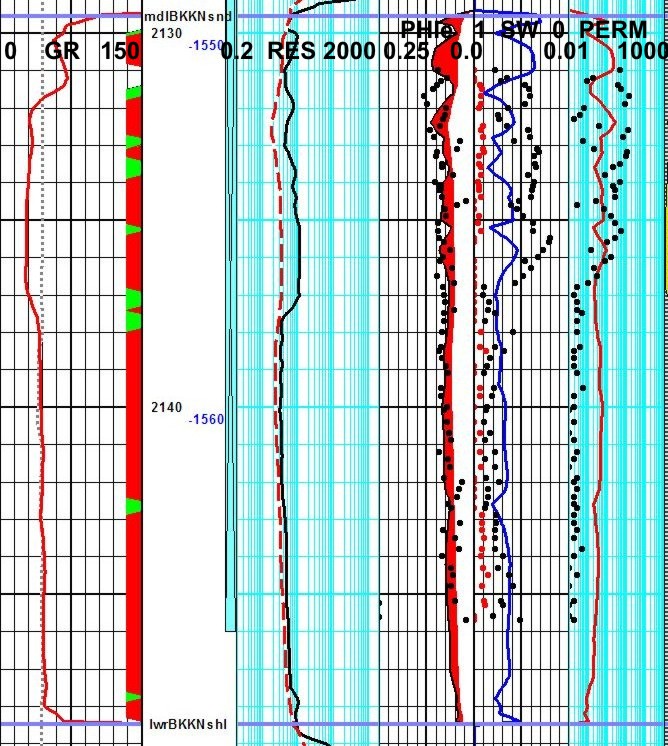

Bakken “Tight Oil” example has no kerogen in the productive sand /

silt section but very high kerogen content in the shales above and

below. Zone is radioactive due to uranium carried from the source

rocks during oil migration. Log example showing core porosity (black dots), core oil saturation (red dots).

core water saturation (blue dots), and permeability (red dots). Note

excellent agreement between log analysis and core data. Separation between red dots and blue

water saturation curve indicates significant moveable oil, even

though water saturation is relatively high (see text below for

explanation). NOTE that the organic rich Upper and Lower Bakken

Shales are much more resistive than the Middle Bakken Sand/Silt pay

zone due to the high TOC content in the shale. There is no

significant kerogen in the sand itself.

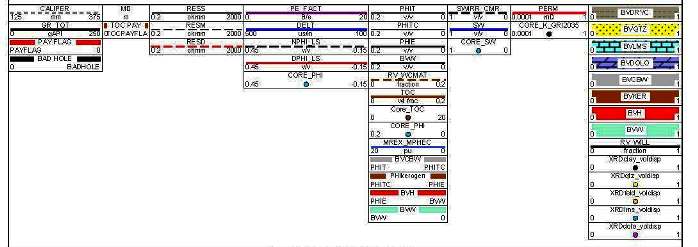

This is a genuine mature kerogen "shale oil" play from South America with lots of kerogen throughout

the reservoir, compared to the Bakken example that has virtually

none. The brown shading is the kerogen volume in the center track,

oil is red, water is light blue. Left edge of the red shading is

effective porosity from shale and kerogen corrected density neutron

porosity model. The core porosity and water saturation match the log

analysis values closely. TOC and clay volume from an offset well

were used to calibrate TOC models: Issler (orange) and Passey (blue)

on the left edge of the porosity track.

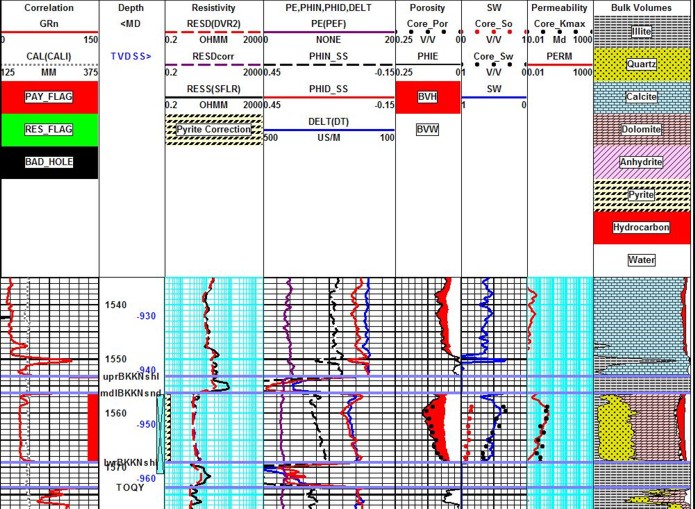

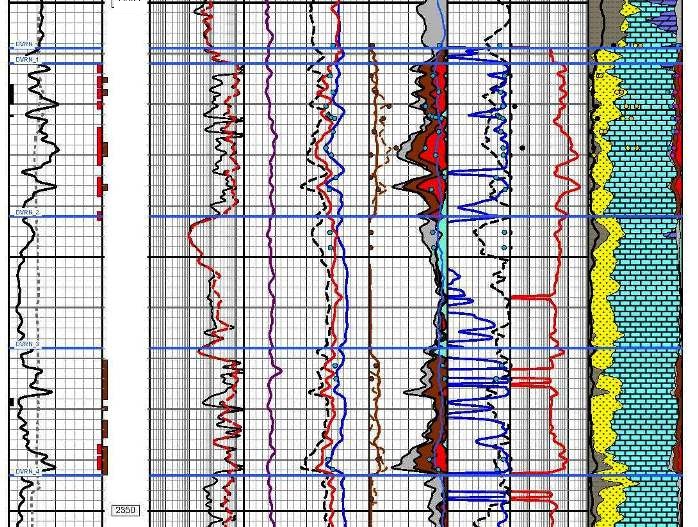

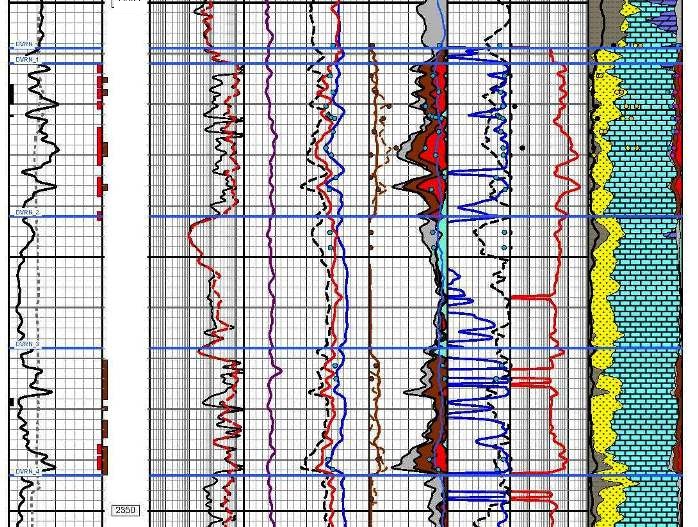

This Duvernay example shows the TOC from ECS and Issler methods

(left side of porosity track) and clay volume from ECS and total

gamma ray (left side of lithology track). The dark shading in the

porosity track is kerogen volume, red is oil, and light blue is

water. Water saturations are very low and agree with core data, as

does the porosity. CMR porosity is also available (blue curve in

porosity track). Pay flags for porosity > 3% (red bar) and for TOC >

2% (brown bar) are on left side of depth track. In this example, the

better porosity is not at the same depths as the high TOC content.

Where would you put the horixontal well?

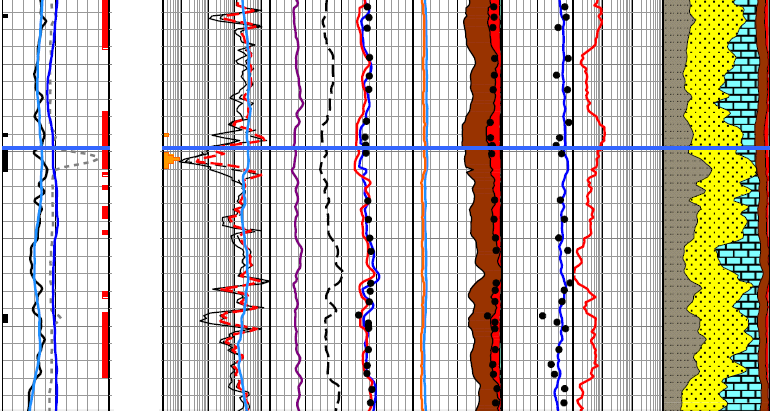

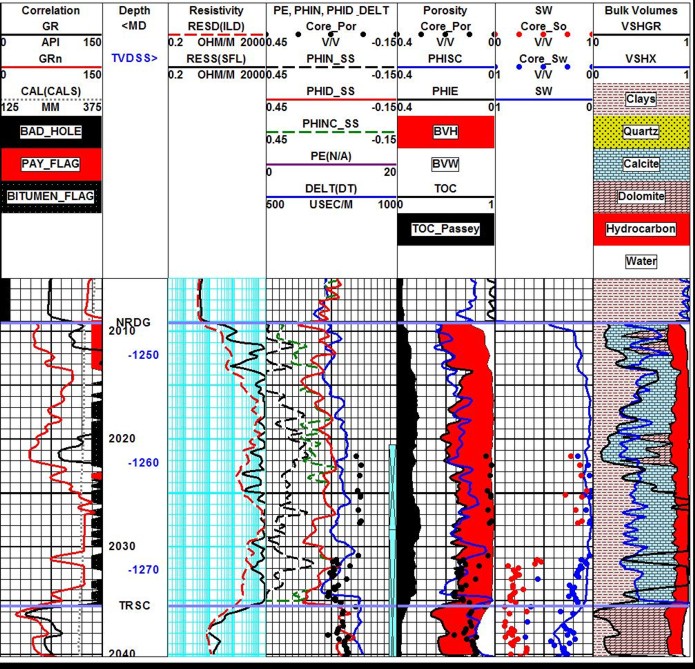

Example of a well in the Nordegg “tight oil” play. This well

is “tight” because of pyrobitumen filling most of the porosity. Core porosity (black dots) is

equivalent to effective porosity. Core oil saturation is very

high (red dots in saturation track, indicating a high fraction of

residual oil, except in the bottom 2 meters where some oil may be

moveable. Core water saturation is very

low (blue dots) as is computed water saturation. The red shading between the core porosity dots and the

water (white) may indicate moveable oil, but it could be a residual

liquid phase. “Pay Flag” is black

to indicate pyrobitumen, instead of red that would indicate mobile

fluids..

BAKKEN GEOLOGY

BAKKEN GEOLOGY

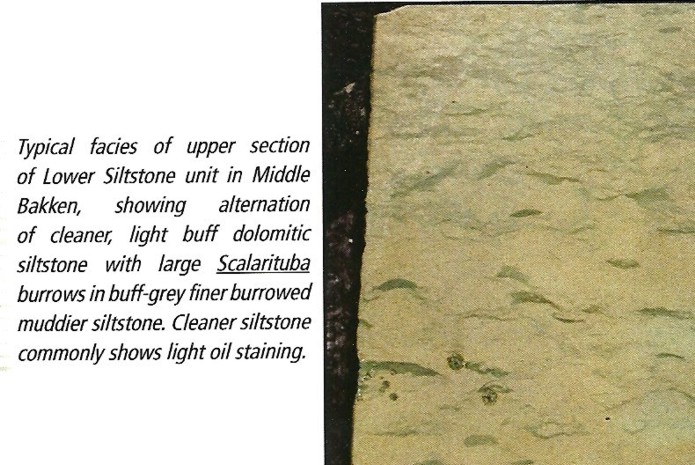

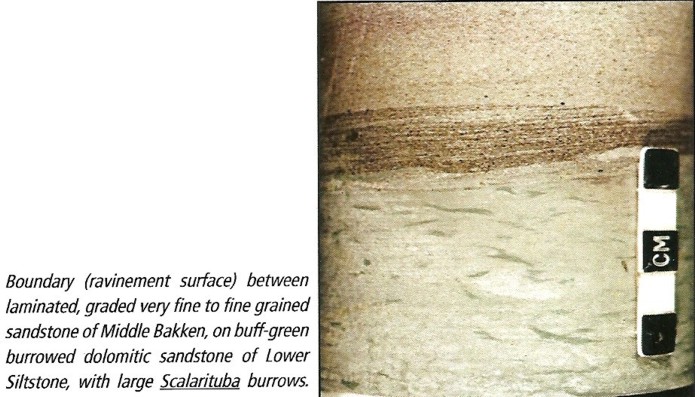

Oil in the Bakken in

southeastern Saskatchewan has migrated from mature Bakken source

rocks in North Dakota and Montana. The best reservoir is associated

with the Upper Middle Bakken Sandstone Facies (BF4). Average

porosity ranges from 14% to 16% and permeabilities are 20 to 80

millidarcies. The unconventional siltstone reservoir (BF2) averages

9% to 12% porosity and 0.01 to 1.0 millidarcies. In the deeper North

Dakota wells, porosity is somewhat lower but permeability may be

higher. All facies types have been exploited in different parts of

the Basin.

These facies were deposited during the late Devonian

and early Mississippian in what was then a tropical setting. The

sediment is believed to have an aeolian source and was blown into

the marine environment from the adjacent arid landmass to the east

and reworked into the various marine facies. The organic rich Upper

and Lower Bakken shales are the source rocks for the sand and silt

reservoirs.

The sands and silts are highly

dolomitic, averaging about 50% dolomite. In deeper wells, calcite

may replace some of the dolomite or infill some porosity.

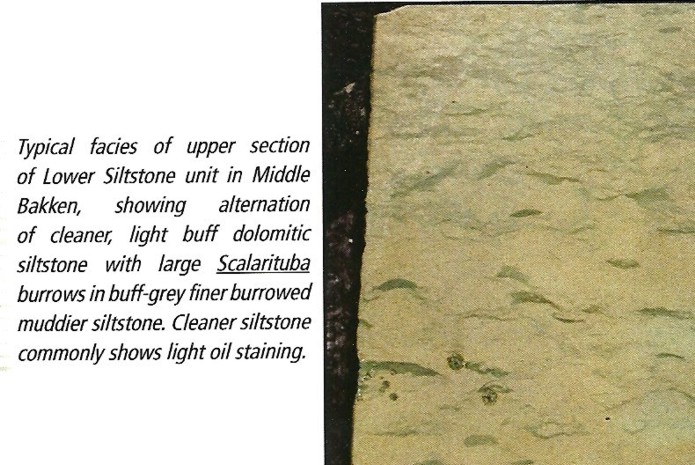

Many of the dominant

features of the Bakken are below the resolution of logging tools and

are best seen in core photos and core logs, as shown below.

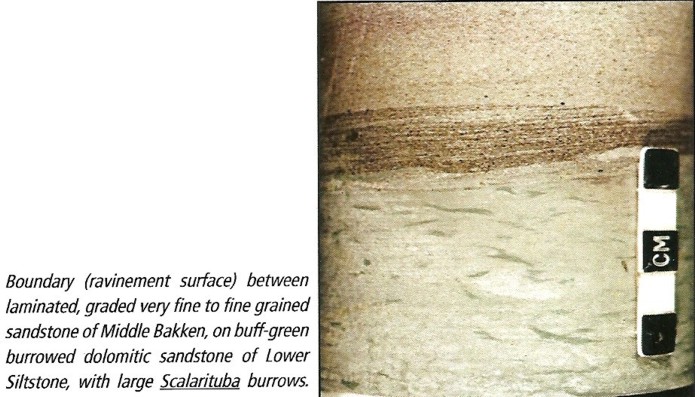

Core photo of Middle Bakken burrowed siltstone

Core photo of Middle Bakken laminated fine grained sandstone

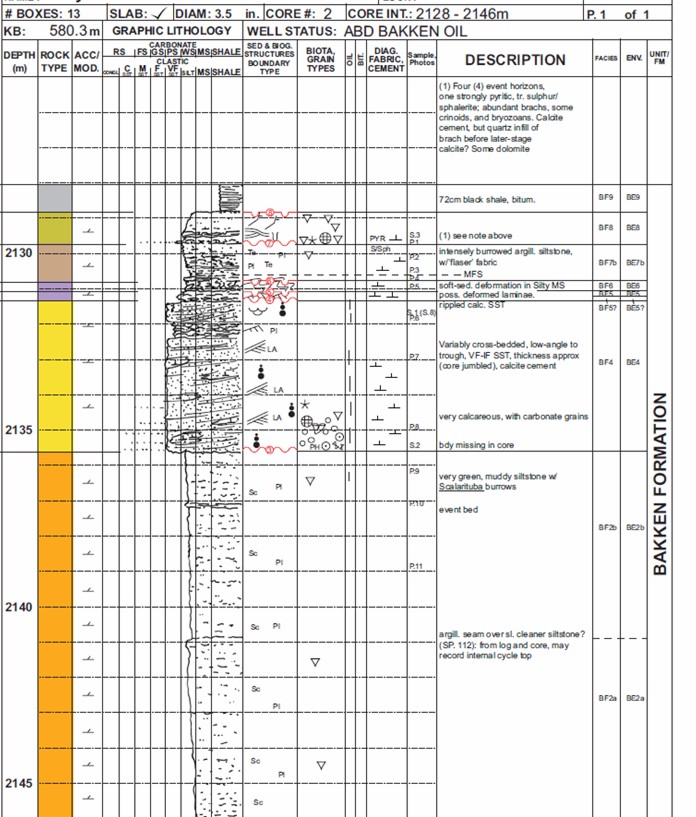

While

laminated shaly sands are best known, laminated porosity is also a

problem for log analysts. The Bakken and Montney reservoirs in

Canada are good examples. The illustrations below give a clear

example of how porosity logs and analysis results smooth out the

porosity variations, which in turn smooth out the saturation and

permeability answers. The latter is especially critical, since

productivity estimates for laminated reservoirs can be seriously

under-estimated because the high permeability streaks tend to be

ignored.

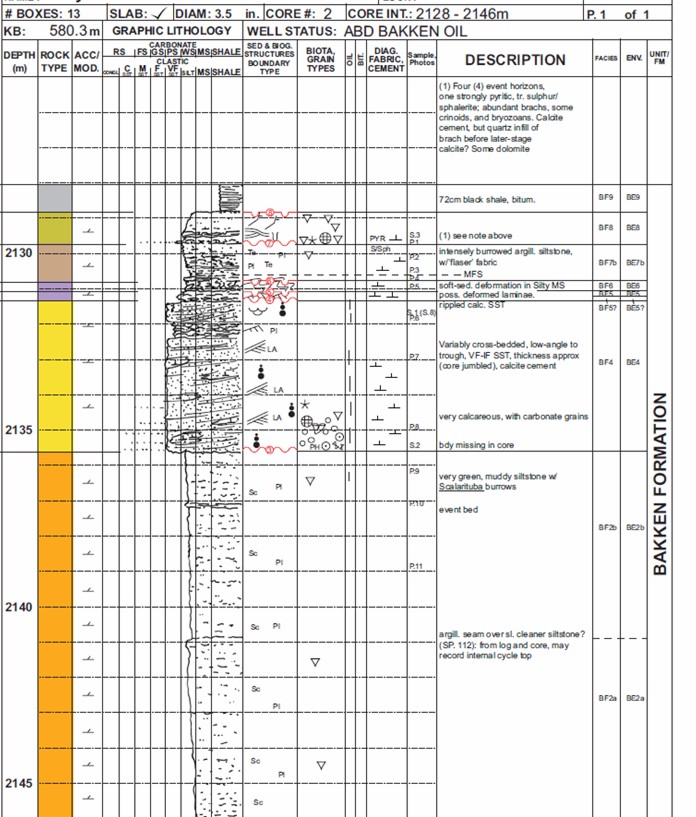

Core description log in a laminated Bakken sand. Upper half of

interval is highly laminated, lower half has thicker beds. See plot

of core data below. (Illustration courtesy Graham Davies Geological

Consulting)

Expanded vertical scale log (grid lines = 1 meter) illutrating

different resolution of logs and core data.

Closely spaced core samples demonstrate laminated nature of Bakken

sand, compared to the running average created by well logs. Distinct

coarsening upward and fining upward sequences can be seen in the

upper half of core (grid lines are 1 meter). The lower half of the

cored interval is less laminated, so porosity and permeability

variations are smaller. Longer running average on resistivity log

makes water saturation even more difficult to assess and comparison

to core is worse than for porosity and permeability

Logs and core are for same well as core description shown above.

In

Saskatchewan, the naturally low resistivity in Bakken pay zones is

further aggravated by thin clay laminations, clay filled burrows,

laminated porosity, and dispersed pyrite.

Even more

confusing is the water resistivity variation on the northwest and

northeast edges of the Basin. Here, wet wells have higher

resistivity than oil wells further south because the water

resistivity is 5 to 20 times higher than deeper in the Basin. This

results from fresher water recharge from the Black Hills of North

Dakota. An adequate production testing program is the only solution

to this issue, as there is no log analysis model that will predict

water resistivity in this reservoir.

Water salinity in the deeper North Dakota wells reaches 325,000 ppm,

making for exceedingly low water resistivity. In Saskatchewan,

salinity is usually at 200,000 ppm or more, but can be as low as

25,000 in the recharge area. Pore geometry in the deeper parts is

more intergranular in texture and irreducible water saturation is

lower than in Saskatchewan.

Typical SW in

Saskatchewan averages 50% grading southward to about 30% in the

deeper North Dakota wells. Very low apparent SW in Saskatchewan

usually means fresh water recharge, possibly with some residual oil.

The "best-looking" wells are actually water producers, but have

measured resistivity values 2 to 4 times higher than productive oil

wells. Water resistivity values are sparse, so any water recovery

should be sent to the lab and analyzed.

The low

resistivity, high radioactivity, large density neutron separation

caused by dolomite and pyrite, and the high PE value (near 3)

conspire to make the zone look like shale on logs. Worse, some

literature continues to name the producing zone the Bakken Shale,

even though we know the Middle Bakken is a radioactive dolomitic

sand or siltstone. These conflicts in the conventional data suggest

strongly that some special core analysis should be done, namely

electrical properties, capillary pressure, X-Ray diffraction and

thin section mineralogy, and anything else that can help explain the

petrophysical response to these complex rocks.

The Bakken is

now the biggest oil play in North America, and may ultimately be the

largest ever found, even larger than Alaska North Slope. It is

sometimes termed an "unconventional" reservoir, due to the low

permeability of the siltstone intervals. In North Dakota, it is also

called a "resource" play because the oil was formed in place (from

the Upper and Lower Bakken Shales), although in Saskatchewan the oil

migrated from the deeper parts of the basin, and is not strictly

speaking a resource play there. Alberta and Montana is also probably

a resource play, but few facts have been published so it is hard to

tell.

Vertical

wells are not overly prolific due to the low intrinsic permeability

of the silty sand, but most horizontal wells do OK. In the deep,

hot, over-pressured region in North Dakota, some wells are flowing

1000 to 2000 barrels per day.

Core

analysis techniques, in particular the sampling interval, are

important in assessing tight oil or gas. Many, like the Bakken and

Montney plays, show a laminated porosity sequence. It is easy to

pick only the best sands, or otherwise obtain unrepresentative

samples. Since permeability is an exponential function of porosity

(as a general rule), small porosity variations make a big

difference in productivity estimates. The detail matters, and since

logs average about 1 meter of rock, log analysis permeability is

often pessimistic, even though the average porosity is correct. At

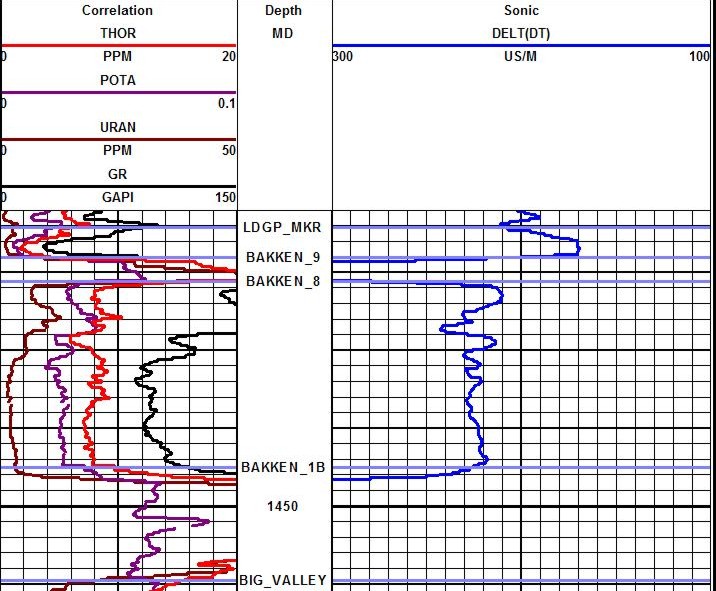

the right is the core and sonic log data for a Bakken well, showing

that the log cannot track the fine detail seen in the core. Many

core analyses take far fewer samples, so the laminated nature of the

reservoir is masked by too coarse a sample interval. Core

analysis techniques, in particular the sampling interval, are

important in assessing tight oil or gas. Many, like the Bakken and

Montney plays, show a laminated porosity sequence. It is easy to

pick only the best sands, or otherwise obtain unrepresentative

samples. Since permeability is an exponential function of porosity

(as a general rule), small porosity variations make a big

difference in productivity estimates. The detail matters, and since

logs average about 1 meter of rock, log analysis permeability is

often pessimistic, even though the average porosity is correct. At

the right is the core and sonic log data for a Bakken well, showing

that the log cannot track the fine detail seen in the core. Many

core analyses take far fewer samples, so the laminated nature of the

reservoir is masked by too coarse a sample interval.

TIGHT OIL SHALE VOLUME CALCULATIONS

TIGHT OIL SHALE VOLUME CALCULATIONS

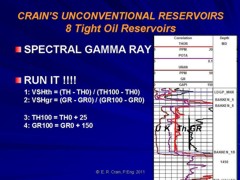

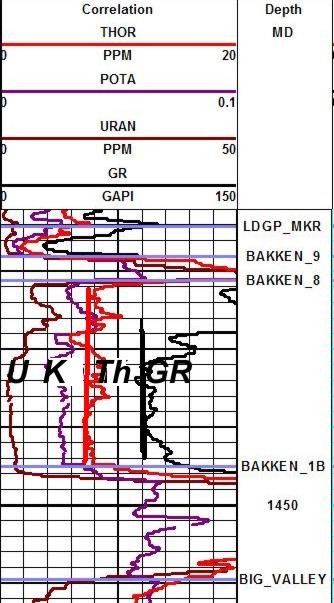

The Bakken is radioactive due mainly to uranium that migrated with

the oil. This can be identified with a spectral gamma ray log and it

should always be run when penetrating radioactive sands. Sadly, it

is often not requested, even though the service is cheap and costs

no extra rig time.

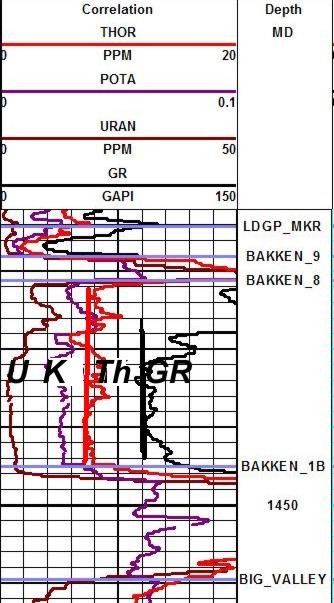

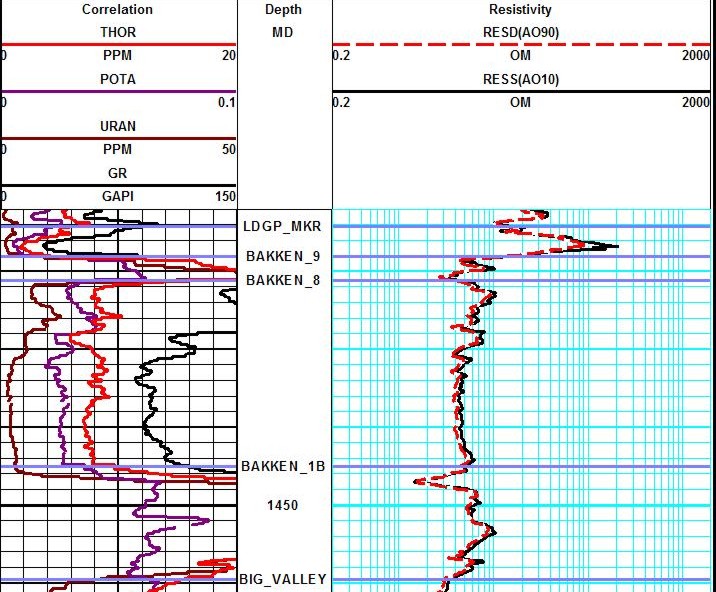

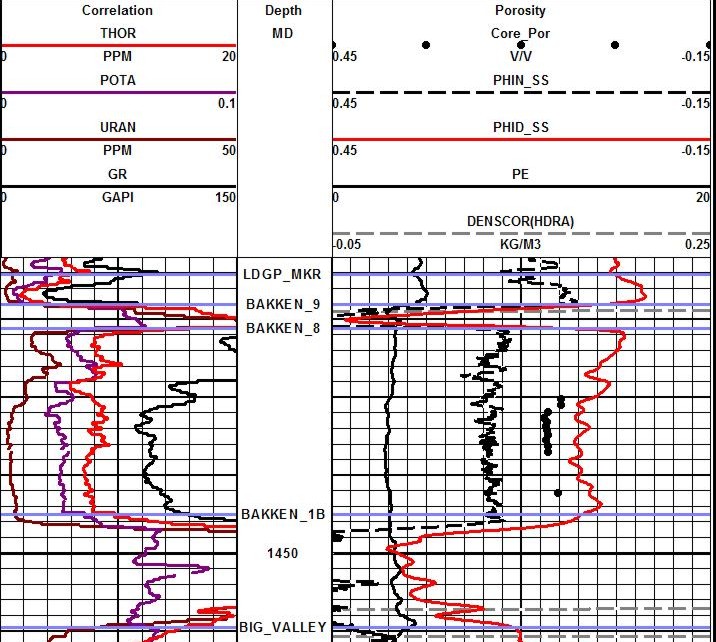

Spectral gamma ray log shows

Uranium (U), Potassium (K), Thorium (Th), and standard gamma ray (GR).

Red vertical line is TH0, the clean line for the Thorium curve, and

the black vertical line is GR0, the clean line for the GR curve.

Bakken 8 is top of sand and Bakken 1B is base of sand.

The Thorium curve is best for shale volume calculations. The SP is

flat and useless, Density neutron separation is mostly due to

dolomite so it cannot be used. The gamma ray can be used in the

absence of the Thorium curve by assuming Uranium content is

constant.

1: VSHth = (TH - TH0) / (TH100 - TH0)

2: VSHgr = (GR - GR0) / (GR100 - GR0)

The Clavier correction to the gamma ray result is often used to

smooth out minor variations in uranium content that make the gamma

ray look "noisy":

3: VSHclavier = 1.7 - (3.38 - (VSHgr + 0.7) ^ 2) ^ 0.5

Choose VSHth in preference to VSHgr or VSHclavier when the thorium

curve is available. This becomes Vsh for all future calculations.

The clean lines TH0 and GR0 are

easy to pick (red and black lines on the illustration). Shale lines

are harder as they are often off-scale to the right or buried under

a plethora of backup curves. In the absence of a good pick from the

log, use:

4: TH100 = TH0 + 25

5: GR100 = GR0 + 150

Adjust the constants to suit your

local knowledge.

IMPORTANT: Remember that all log analysis models for TOC are

calibrated to standard geochemistry lab data that often do not

discriminate between kerogen and pyrobitumen. Either or both may be

present. Both have variable but fortunately similar physical

propertiees so converting log derived TOC to "kerogen" may actually

be a conversion to pyrobitumen or a mixture of the two components.

In the following material, you may want to substitute the words

"Organic Matter" for "Kerogen" to be more general.

KEROGEN volume

KEROGEN volume

Some tight oil / shale oil plays contain kerogen,

just like shale gas plays. Little of the adsorbed gas in the kerogen

will move so we do not calculate adsorbed gas. But the kerogen does

affect our porosity calculation i so we must calculate and account

for the kerogen.

Kerogen volume is calculated by

converting the TOC weight fraction derived from density vs

resistivity or sonic vs resistivity methods, calibrated to

geochemical lab data.

0: Wtoc = TOC% / 100

5: Wker = Wtoc / KTOC

6: VOLker = Wker / DENSker

7: VOLma = (1 - Wker) / DENSma

8: VOLrock = VOLker + VOLma

9: Vker = VOLker / VOLrock

Where:

KTOC = kerogen correction factor - Range = 0.68 to 0.90, default

0.80

Wker = mass fraction of kerogen (unitless)

DENSker = density of kerogen (kg/m3 or g/cc)

DENSma = density log reading (kg/m3 or g/cc)

VOLxx = component volumes (m3 or cc)

Vker = volume fraction of kerogen (unitless)

DENSker is in the range of 0.95 to 1.45 g/cc (975 to 1450

kg/m3), similar to good quality coal.

Default = 1.26 g/cc (1200 kg/m3)

TIGHT OIL POROSITY CALCULATIONS

TIGHT OIL POROSITY CALCULATIONS

Even though the Bakken is a complex mixture of quartz, dolomite,

calcite, and sometimes pyrite, with a little clay, the standard

density neutron complex lithology crossplot model works well:

6: PHIdc = PHID

– (Vsh * PHIDSH) – (Vker * PHIDker)

7: PHInc = PHIN

– (Vsh * PHINSH) – (Vker * PHINker)

8: PHIe

= (PHInc + PHIdc) / 2

TIGHT OIL WATER SATURATION CALCULATIONS

TIGHT OIL WATER SATURATION CALCULATIONS

Since there is little clay, the Archie model can be used, although

it costs nothing extra to use a shale corrected saturation equation

such as Simandoux or Dual Water:

9:

IF PHIe > 0.0

10: THEN C = (1 - Vsh) * A * (RW@FT) / (PHIe ^ M)

11: D = C * Vsh / (2 * RSH)

12: E = C / RESD

13: Sws = ((D ^ 2 + E) ^ 0.5 - D) ^ (2 / N)

14: OTHERWISE Sws = 1.0

Electrical properties variations

between facies and with depth or diagenesis are not published. This

lab work is worth the effort, as considerable increases in oil in

place are possible with small reductions in M and N values.

Tight oil and shale oil reservoirs are not "average" sandstones, so the electrical properties must be varied from

world average values in common use (A = 1, M = N = 2.0). To get

log analysis Sw to match lab data, much lower values are needed. Typically, A =

1.0 with M = N = 1.5 to 1.8. Unless lab derived properties are

available, vary M and N to obtain a good match to core Sw. If core

Sw is not available, the recommended default is M = N = 1.7.

Fresh

water recharge in the north can confuse log analysis results, so a

production test is essential before drilling any horizontal wells.

TIGHT OIL PERMEABILITY CALCULATIONS

TIGHT OIL PERMEABILITY CALCULATIONS

There is no strong correlation between porosity and permeability has

been seen. The illustrations below show the scatter is large. The

Wyllie Rose equation gives rational values and can be tuned to fit

smoothed core data:

15: Kmax = 100 000 * (PHIe^6) / (SWir^2)

Permeability versus porosity scatter

plots for North Dakota well (left) and Saskatchewan well (right).

The scatter suggests microfractures.

TIGHT OIL Lithology CALCULATIONS

TIGHT OIL Lithology CALCULATIONS

How

do we know which minerals to use in the petrophysical log analysis?

Detailed sample descriptions are a good start. Both X-Ray diffraction data and thin section point counts can be

used. Both methods are considered semi-quantitative and come from

tiny samples compared to the volume measured by logs. So we don't

get too excited about obtaining a close numerical match . How

do we know which minerals to use in the petrophysical log analysis?

Detailed sample descriptions are a good start. Both X-Ray diffraction data and thin section point counts can be

used. Both methods are considered semi-quantitative and come from

tiny samples compared to the volume measured by logs. So we don't

get too excited about obtaining a close numerical match .

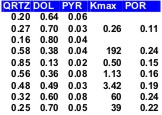

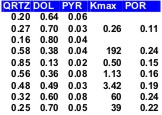

Mineral and core

analysis summary for a Bakken reservoir

Standard 3-mineral models using PE, density, and neutron data are

used with appropriate parameters for the selected minerals.

Multi-mineral solvers can be used if spectral gamma ray data is

available. In this case, shale volume would be derived also.

PYRITE CORRECTIONS

PYRITE CORRECTIONS

Pyrite is a

conductive metallic mineral that may occur in many different

sedimentary rocks. It can reduce measured resistivity, thus

increasing apparent water saturation. The conductive metallic

current path is in parallel with the ionic water conductive

path. As a result, a correction to the measured resistivity can

be made by solving the parallel resistivity circuit.

Although the math is simple, the parameters needed are not well

known. The two critical elements are the volume of pyrite and the

effective resistivity of pyrite. Pyrite volume can be found from a

two or three mineral model,

calibrated by thin section point counts or X-ray diffraction data.

The

resistivity of pyrite varies with the frequency of the logging tool

measurement system. Laterologs measure resistivity at less than 100

Hz, induction logs at 20 KHz, and LWD tools at 2 MHz. Higher

frequency tools record lower resistivity than low frequency tools

for the same concentration of pyrite. The variation in resistivity

is caused by the fact that pyrite is a semiconductor, not a metallic

conductor. It is nature's original transistor, and formed the main

sensing component in early radios.

Typical resistivity of pyrite

is in the range of 0.1 to 1.0 ohm-m; 0.5 ohm-m seems to work

reasonably well. The effect of pyrite is most noticeable when RW is

moderately high and less noticeable when RW is very low.

The

math is easiest when conductivity is used instead of resistivity:

16: CONDpyr = 1000 / RESpyr

17: CONDcorr = 1000 / RESD - CONDpyr * Vpyr

18: RESDcorr = 1000 / CONDcorr

The corrected resistivity can be plotted versus depth, along

with the original log.

Corrected water saturation will always be lower or equal to the

original Sw.

If CONDcorr goes negative, lower Vpyr or raise RESpyr

RESERVOIR QUALITY FROM CAP PRESSURE

RESERVOIR QUALITY FROM CAP PRESSURE

A

capillary pressure (Pc) data set, along with some

calculated parameters, is summarized in the table

below.

|

CAPILLARY PRESSURE SUMMARY |

|

Sample |

Depth |

Perm |

PHIe |

SWir |

SWir |

PHI*SW |

PHI*SW |

sqrt/PHIe) |

Pore Throat |

|

|

m |

mD |

|

425m |

100m |

425m |

100m |

|

Radius um |

|

Bakken |

|

|

|

|

|

|

|

|

|

|

1 |

03.5 |

2.40 |

0.118 |

0.12 |

0.19 |

0.014 |

0.022 |

4.51 |

1.358 |

|

2 |

04.3 |

0.24 |

0.137 |

0.62 |

0.94 |

0.085 |

0.129 |

1.32 |

0.036 |

|

3 |

04.5 |

0.32 |

0.139 |

0.39 |

0.64 |

0.054 |

0.089 |

1.52 |

0.100 |

|

4 |

05.2 |

0.77 |

0.149 |

0.31 |

0.62 |

0.046 |

0.092 |

2.27 |

0.113 |

|

Average |

04.4 |

0.93 |

0.136 |

0.36 |

0.60 |

0.050 |

0.083 |

2.41 |

0.402 |

|

|

|

|

|

|

|

|

|

|

|

|

Torquay |

|

|

|

|

|

|

|

|

|

|

5 |

16.8 |

0.05 |

0.163 |

1.00 |

1.00 |

0.163 |

0.163 |

0.55 |

0.008 |

|

6 |

20.4 |

0.07 |

0.145 |

0.59 |

0.97 |

0.086 |

0.141 |

0.69 |

0.038 |

|

7 |

21.8 |

0.09 |

0.174 |

0.79 |

0.96 |

0.137 |

0.167 |

0.72 |

0.019 |

|

8 |

23.8 |

0.03 |

0.157 |

1.00 |

1.00 |

0.157 |

0.157 |

0.44 |

0.009 |

|

9 |

31.4 |

0.07 |

0.138 |

0.83 |

0.98 |

0.115 |

0.135 |

0.71 |

0.017 |

|

Average |

24.4 |

0.07 |

0.154 |

0.80 |

0.98 |

0.124 |

0.150 |

0.64 |

0.021 |

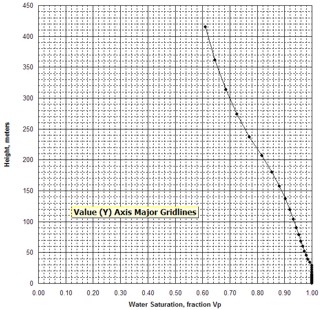

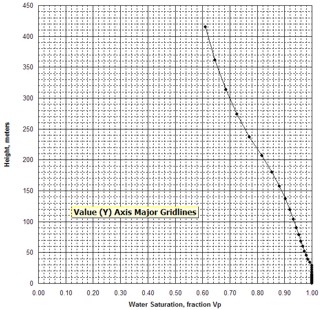

In

higher permeability rock, the cap pressure curve quickly reaches an

asymptote and the minimum saturation usually represents the actual

water saturation in an undepleted hydrocarbon reservoir above the

transition zone. In tight rock, the asymptote is seldom reached, so

we pick saturation values from the cap pressure curves at two

heights (or equivalent) Pc values) to represent two extremes of

reservoir condition. In

higher permeability rock, the cap pressure curve quickly reaches an

asymptote and the minimum saturation usually represents the actual

water saturation in an undepleted hydrocarbon reservoir above the

transition zone. In tight rock, the asymptote is seldom reached, so

we pick saturation values from the cap pressure curves at two

heights (or equivalent) Pc values) to represent two extremes of

reservoir condition.

Only sample 1 in the above table behaves close to

asymptotically, as in curve A in the schematic illustration at the

right. All other samples behave like curves B and C (or worse). The

real cap pressure curves for samples 1 and 2 are shown below.

Examples of capillary pressure curves in good quality rock (sample 1

– left) and poorer quality rock

(sample 2 – right)

The summary table shows wetting phase saturation

selected by observation of the cap pressure graphs at two

different heights above free water, namely 100 meters and 425 meters

in this example. In this case, the 100 meter data gives water

saturations that we commonly see in petrophysical analysis of well

logs in hydrocarbon bearing Bakken reservoirs in Saskatchewan. This

is a pragmatic way to indicate the water saturation to be expected

when a Bakken reservoir is at or near irreducible water saturation.

The data for the 450 meter case is considerably lower and probably

does not represent reservoir conditions in this region of the

Williston Basin.

Two other columns in the table are

calculated from the primary measurements.

The first is the product of porosity times

saturation, PHI*SW, often called Buckle’s Number. It is considered

to be a measure of pore geometry or grain size. Higher values are

finer grained rocks. These values vary considerably in the Bakken,

between low and medium values, indicating the laminated nature of

the silt / sand reservoir. The values in the Torquay are uniformly

high, indicating that the reservoir is poor quality in all samples.

The second is the square root of permeability divided

by porosity, sqrt(Kmax/PHIe), which is another measure of reservoir

quality, directly proportional to pore throat radius and Pc. High

numbers represent good connectivity and low values show poor

connectivity. Again, the Bakken shows the variations due to

laminations, and the Torquay shows low values and unattractive

reservoir quality.

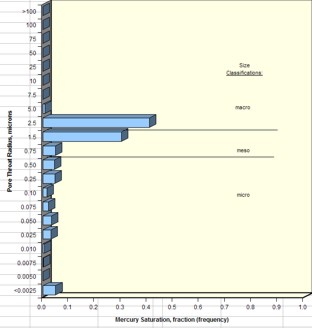

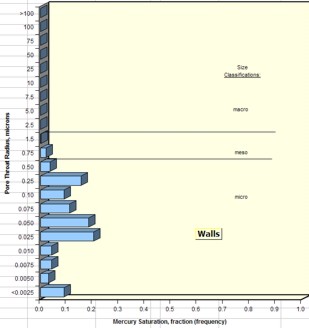

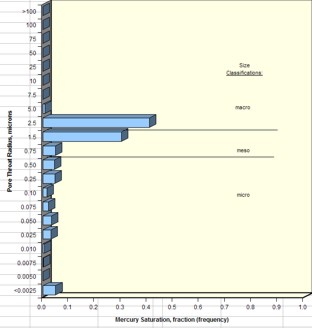

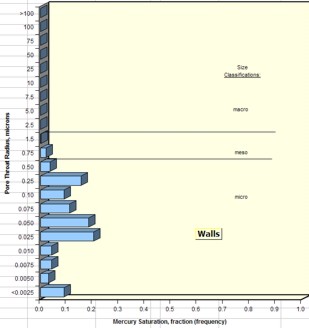

Examples of pore throat radius distribution

in good quality rock (sample 1 – left) and poorer quality rock

(sample 2 – right)

By comparing cap pressure and pore throat

distribution graphs from each sample with the quality indicator

values in the summary table, it becomes more evident as to which

parameters in a petrophysical analysis might be the best indicator

of reservoir quality. Since both Buckle’s Number and the Kmax/PHIe

parameter can be determined from logs, it has been relatively common

to assess reservoir quality from these parameters as a proxy for

capillary pressure and pore throat measurements.

However, in thinly laminated reservoirs like the

Bakken, this is not always possible since the logging tools average

1 meter of rock. This means we cannot see the internal variations of

rock quality evident in the core data.

BAKKEN EXAMPLES

BAKKEN EXAMPLES

Example 1: Bakken, SE Saskatchewan

Example 1: Bakken, SE Saskatchewan

Resistivity log on low

resistivity, radioactive Bakken sand (4 ohm-m in best sand). Note high resistivity upper

and lower shales, which are the source rock for the oil in the sand.

These are "real" shales with gamma ray readings between 250 and

500

API units. Spectral GR shows low but significant uranium content in

sand and very high uranium

in the shales, associated with the kerogen content. The thorium

curve is the best clay indicator.

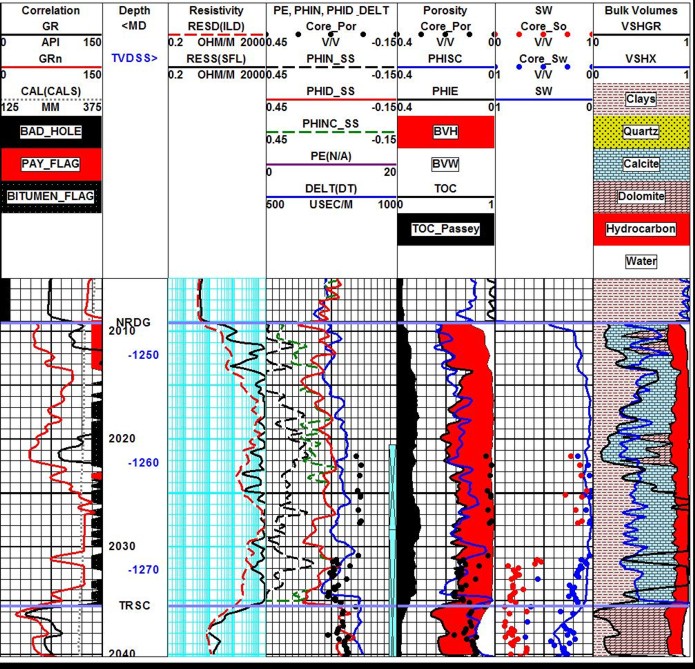

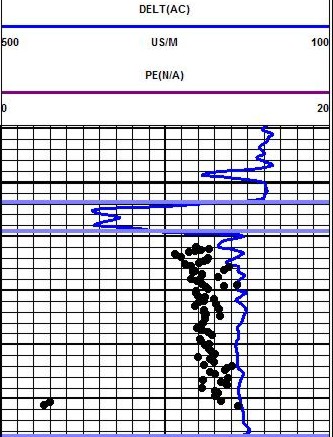

Density neutron logs on low

resistivity, radioactive, dolomitic Bakken sand. Note high apparent

porosity (almost coal values) in upper and lower shales. Density neutron separation and PE show a 50-50 mix of

quartz and dolomite with a few percent pyrite. XRD and sample

descriptions confirm this

analysis.

The

sonic log is also

useful in a 3 or 4 mineral model and for calculating porosity in

older wells that have no density neutron logs. Matrix travel time

needs to be calibrated to allow a match to core.

The answer plot illustrates the mineral mix and the good match to core

porosity and permeability that was achieved. The curves in the

correlation track are, from left to right, uranium, potassium,

thorium, total gamma ray.

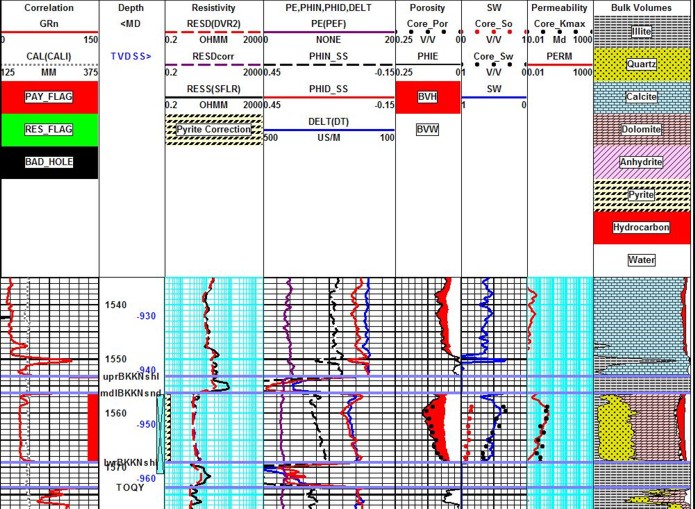

Example 2: Bakken, SE Saskatchewan With Pyrite Correction

Example 2: Bakken, SE Saskatchewan With Pyrite Correction

Here is a different well with the pyrite correction applied to the

resistivity log. The before and after

versions of the resistivity are shown in Track 2, along with the

pyrite fraction determined from a

3-mineral model using PE-density-neutron logs. The correction raises

the resistivity about 0.5

ohm-m and reduces water saturation by about 10%. Making the pyrite

more conductive would

raise RESD further, but as yet no one has provided any public

capillary pressure data in this area

to calibrate SW. The SWir from an NMR log would also help calibrate

this problem.

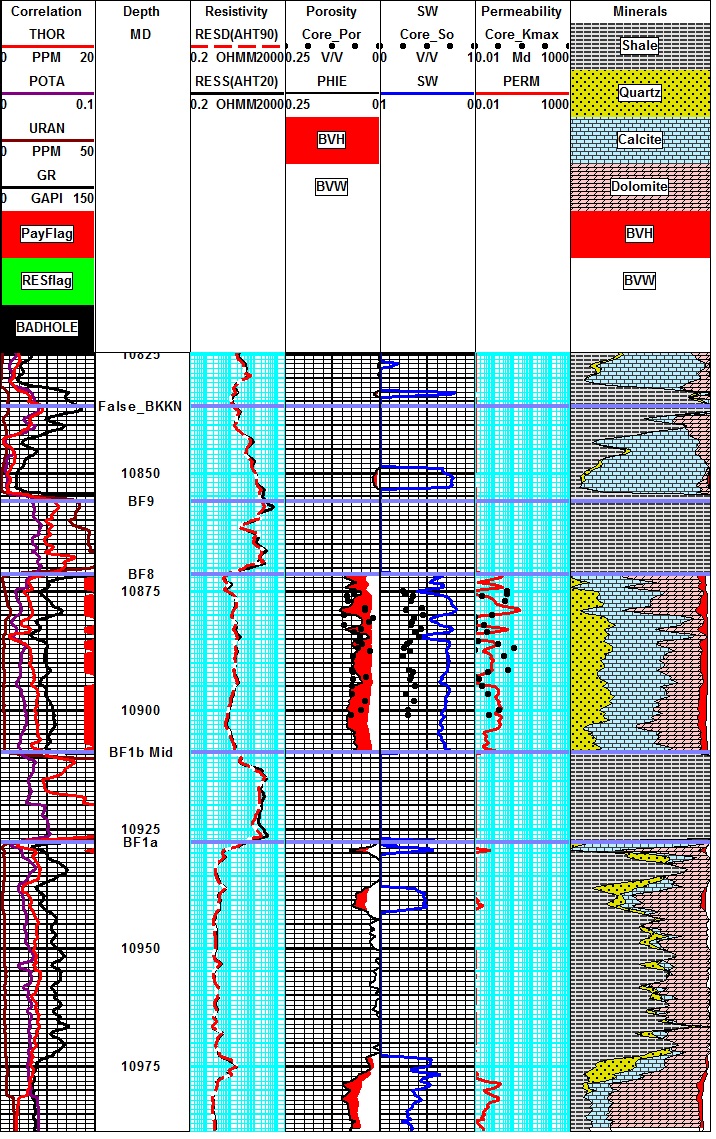

Example 3: Bakken, North Dakota

Example 3: Bakken, North Dakota

This example is from the deeper, hotter, overpressured part of the

Williston Basin. Depths are in feet, porosity and permeability are

lower than the Saskatchewan examples shown earlier, but the zone is

thicker. Water resistivity is very low due to saturated salt water

(320,000 ppm) and high temperature (200+F). Note the possibility of

hydrocarbons below the Lower Bakken Shale.

CARDIUM, VIKING, DUNVEGAN EXAMPLES

CARDIUM, VIKING, DUNVEGAN EXAMPLES

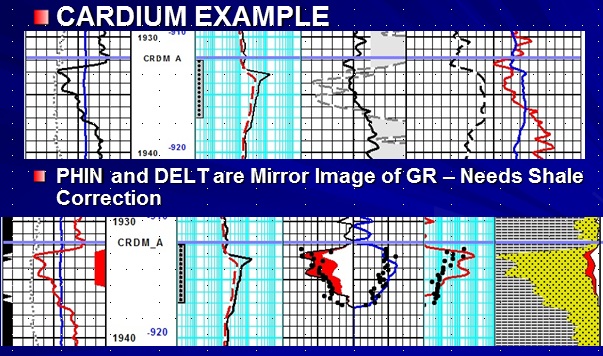

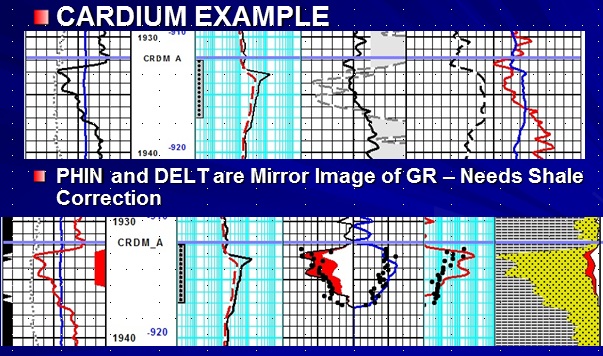

Example 4: Cardium, Alberta

Many “Tight Oil” plays are really “Old Oil” plays, usually gas

expansion drive reservoirs with low recovery factors. Laminations

(seen here on the core porosity) and high shale volume suggest that

some of the perforated interval has not yet been produced. Whether

these wells produce gas only or gas plus oil depends entirely on

intrinsic permeability and oil gravity - low perm can only make gas,

higher perm can let out some oil. Stimulation may increase oil rate..

Example 5: Viking, Alberta

The Viking is also a laminated, shaly, gas expansion drive

reservoir with a low recovery factor on initial completion.

Horizontal wells with a modern stimulation (massive hydraulic frac

job) improve recovery factor and flow rates. Conventional

petrophysical models work well. Tight streaks act as baffles, not

barriers, and can only be seen in micrologs, resistivity image logs,

or detailed core descriptions.

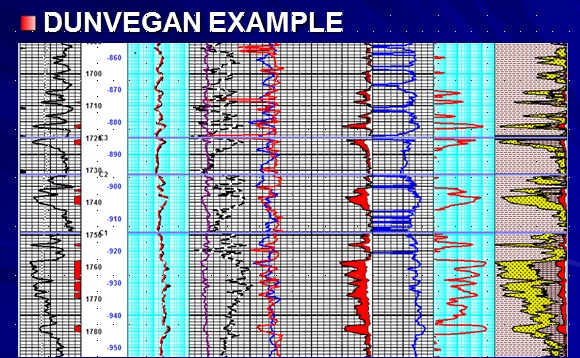

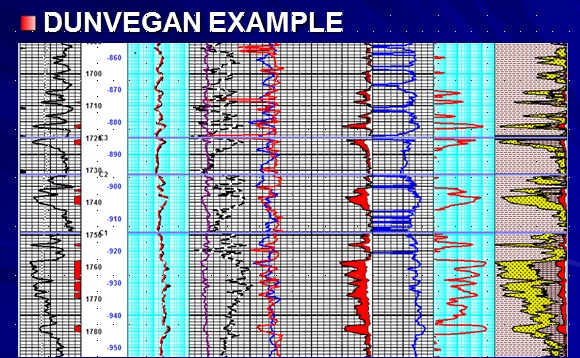

Example 6: Dunvegan, Alberta

Another tight oil example is the Dunvegan, a multi-layer sequence of

fining upward and coarsening upward sequences with highly variable

shale volume and porosity. Tight laminations, seen on micrologs, but

not conventional open hole logs, reduce net pay.

|

Core

analysis techniques, in particular the sampling interval, are

important in assessing tight oil or gas. Many, like the Bakken and

Montney plays, show a laminated porosity sequence. It is easy to

pick only the best sands, or otherwise obtain unrepresentative

samples. Since permeability is an exponential function of porosity

(as a general rule), small porosity variations make a big

difference in productivity estimates. The detail matters, and since

logs average about 1 meter of rock, log analysis permeability is

often pessimistic, even though the average porosity is correct. At

the right is the core and sonic log data for a Bakken well, showing

that the log cannot track the fine detail seen in the core. Many

core analyses take far fewer samples, so the laminated nature of the

reservoir is masked by too coarse a sample interval.

Core

analysis techniques, in particular the sampling interval, are

important in assessing tight oil or gas. Many, like the Bakken and

Montney plays, show a laminated porosity sequence. It is easy to

pick only the best sands, or otherwise obtain unrepresentative

samples. Since permeability is an exponential function of porosity

(as a general rule), small porosity variations make a big

difference in productivity estimates. The detail matters, and since

logs average about 1 meter of rock, log analysis permeability is

often pessimistic, even though the average porosity is correct. At

the right is the core and sonic log data for a Bakken well, showing

that the log cannot track the fine detail seen in the core. Many

core analyses take far fewer samples, so the laminated nature of the

reservoir is masked by too coarse a sample interval.

How

do we know which minerals to use in the petrophysical log analysis?

Detailed sample descriptions are a good start. Both X-Ray diffraction data and thin section point counts can be

used. Both methods are considered semi-quantitative and come from

tiny samples compared to the volume measured by logs. So we don't

get too excited about obtaining a close numerical match .

How

do we know which minerals to use in the petrophysical log analysis?

Detailed sample descriptions are a good start. Both X-Ray diffraction data and thin section point counts can be

used. Both methods are considered semi-quantitative and come from

tiny samples compared to the volume measured by logs. So we don't

get too excited about obtaining a close numerical match . In

higher permeability rock, the cap pressure curve quickly reaches an

asymptote and the minimum saturation usually represents the actual

water saturation in an undepleted hydrocarbon reservoir above the

transition zone. In tight rock, the asymptote is seldom reached, so

we pick saturation values from the cap pressure curves at two

heights (or equivalent) Pc values) to represent two extremes of

reservoir condition.

In

higher permeability rock, the cap pressure curve quickly reaches an

asymptote and the minimum saturation usually represents the actual

water saturation in an undepleted hydrocarbon reservoir above the

transition zone. In tight rock, the asymptote is seldom reached, so

we pick saturation values from the cap pressure curves at two

heights (or equivalent) Pc values) to represent two extremes of

reservoir condition.