|

True

Vertical Depth

True

Vertical Depth

In

near-vertical wells, we can be reasonably sure of the depth

to a particular formation. In deviated wells, we need to

calculate true vertical depth to that formation AND place

the location where the wellbore intersects the reservoir.

The results of this calculation allow us to correctly

position reservoirs on geological sections, contour maps,

and 3-D visualizations.

True

vertical depth is a tricky business because six methods have been used

over the years. The results vary in accuracy depending on

how crooked the borehole is and how closely spaced the

survey points are positioned. For a relatively straight

deviated well, the tangential method is easy and quite

adequate. For a well with many twists and turns, and for

horizontal wells, more sophisticated methods are needed. The

minimum curvature method seems to be the most popular.

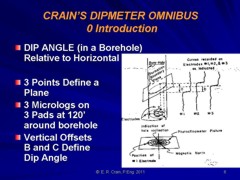

Directional surveys measure wellbore deviation from the

vertical and wellbore direction (azimuth) corrected to true

North. Typical directional surveys are run inside drill

pipe, with data measured every time a new drill pipe

stand is readied for use - this occurs every 100 feet (30

meters) give or take a bit. Older surveys mau have much

longer or erratic spacings between measurements.

With the increased use of horizontal wells in many

reservoirs, the accurate representation of the wellbore

trajectory between measurement stations has become

important, for both practical and legal reasons. The math

for this is a little beyond the scope of this Handbook.

Click

HERE for a description of a

Visual Basic assisted spreadsheet for this purpose. THIS CHAPTER

"A

Compendlum of Directional Calculations Based on the Minimum

Curvature Method", S.J. Sawaryn and I. L. Thorogood, SPE

84246, 2003.

Real-time continuous logging while drilling directional

surveys minimize the calculation problem while geo-steering

directional or horizontal wells. Continuous directional data

from dipmeters, image logs, and other open hole well logs

also give accurate results, but of course are "after the

fact" and cannot help with geo-steering. A virtue of well

logging methods is the ability to log data inbound and

outbound, making for a "closed" survey in which accumulated

closure errors can be distributed around the entire data

set. This cannot be done in conventional station by station

surveys.

CAUTION: If you write your own spreadsheets to run these

calculations, note that the default units for angles is

RADIANS and not degrees. The math below assumes angles are

in degrees except where noted in Method 6.

Tangential Method

Tangential Method

The tangential method uses only the inclination and direction

angles measured at the lower end of the survey course length.

The well bore path is assumed to be a straight line throughout

the course. This method has probably been used more than any other

and is the least accurate. It makes the well appear too shallow

and the lateral displacement too large. In a typical deviated

well, the true vertical depth can be wrong by more than 50 feet.

It

has been used and perpetuated because of its inherent simplicity

of hand calculation. Calculating the survey by the tangential

method, however, is no longer justifiable because programmable

calculators and field portable computers make the better methods

just as easy as this one. This method is not recommended any time

in any well. However, many such surveys are in the well files

and many true vertical depths have been used, and may still be

accepted, based on this erroneous data. All that is needed for

a re-computation using better methods is the raw inclination and

direction data, and this is usually available. Re-computation

is strongly recommended.

If

surveys were taken at approximately 1 ft. intervals, the error

would be tolerable, but this frequency cannot be economically

justified with typical single shot surveys. However, this frequency

of measurement is achieved with continuous directional surveys

run with the dipmeter. If computations are made at short intervals,

then the tangential method works fine. Most station by station

surveys are taken at much larger intervals, such as a few to several

hundred feet apart, and therefore the results are inaccurate.

If the dipmeter program calculates vertical depth at similar intervals,

it is also inadequate.

The

formula are:

1: North = SUM ((MD2 - MD1) * Sin WD2 * Cos HAZ2)

2: East = SUM ((MD2 - MD1) * Sin WD2 * Sin HAZ2)

3: TVD = SUM ((MD2 - MD1) * Cos WD2)

NOTE:

This is the high tangential method. If WD1 and HAZ1 replace WD2

and HAZ2, it is the low tangential method.

Where:

East = easterly displacement (feet or meters) - negative = West

HAZ1 = hole azimuth at top of course (degrees)

HAZ2 = hole azimuth at bottom of course (degrees)

MD1 = measured depth at top of course (feet or meters)

MD2 = measured depth at bottom of course (feet or meters)

North = northerly displacement (feet or meters) - negative = South

TVD = true vertical depth (feet or meters)

WD1 = well deviation at top of course (degrees)

WD2 = well deviation at bottom of course (degrees)

Average Tangential

Method

Average Tangential

Method

The angle averaging method uses the angles measured at both the

top and bottom of the course length in such a fashion that the

simple average of the two sets of measured angles is assumed to

be the inclination and the direction. The wellbore then is calculated

tangentially using these two average angles over the course length.

This method is a very simple, and more accurate, means of calculating

a wellbore survey.

1: North = SUM ((MD2 - MD1) * Sin ((WD2 + WD1) / 2) * Cos ((HAZ2

+ HAZ1) / 2))

2: East = SUM ((MD2 - MD1) * Sin ((WD2 + WD1) / 2) * Sin ((HAZ2

+ HAZ1) / 2))

3: TVD = SUM ((MD2 - MD1) * Cos ((WD2 + WD1) / 2))

Balanced Tangential Method

Balanced Tangential Method

The balanced tangential method uses the inclination and direction

angles at the top and bottom of the course length to tangentially

balance the two sets of measured angles. This method combines

the trigonometric functions to provide the average inclination

and direction angles which are used in standard computational

procedures. The values of the inclination at WD2 and WD1 are combined

in the proper sine-cosine functions and averaged. This method

did not lend itself to hand calculations in the early days, but

modern programmable scientific calculators make the job easy.

This

technique provides a smoother curve which should more closely

approximate the actual wellbore between surveys. The longer the

distance between survey stations, the greater the possibility

of error. The formula are:

1: North = SUM (MD2 - MD1) * ((Sin WD1 * Cos HAZ1 + Sin WD2 *

Cos HAZ2) / 2)

2: East = SUM (MD2 - MD1) * ((Sin WD1 * Sin HAZ1 + Sin WD2 * Sin

HAZ2) / 2)

3: TVD = SUM ((MD2 - MD1) * (Cos WD2 + Cos WD1) / 2)

Mercury Method

Mercury Method

The mercury method is a combination of the tangential and the

balanced tangential method that treats that portion of the measured

course defined by the length of the measuring tool in a straight

line (tangentially) and the remainder of the measured course in

a balanced tangential manner. The name of the mercury method originated

from its common usage at the Mercury, Nevada test site by the

US Government.

1: North = SUM ((MD2 - MD1 - STL)*((Sin WD1 * Cos HAZ1 + Sin WD2

* Cos HAZ2)/2)

+ STL * Sin WD2 * Cos HAZ2)

2: East = SUM ((MD2 - MD1 - STL) * ((Sin WD1 * Sin HAZ1 + Sin

WD2 * Sin HAZ2) / 2)

+ STL * Sin WD2 * Sin HAZ2)

3: TVD = SUM (((MD2 - MD1 - STL) * (Cos WD2 + Cos WD1) / 2) +

STL * Cos HAZ2)

Where:

STL is the length of the survey tool

Radius of Curvature Method

Radius of Curvature Method

The radius of curvature method uses sets of angles measured at

the top and bottom of the course length to generate a space curve

(representing the wellbore path) that has the shape of a spherical

arc passing through the measured angles at both the upper and

lower ends of the measured course. This method is one of the more

accurate means of determining the position of a wellbore when

survey spacing is sparse. The assumption that the wellbore is

a smooth curve between surveys makes this method less sensitive

to placement and distances between the survey points than other

methods.

CAUTION:

It is a terrible method when data is closely spaced, as the subtractions

in the equation create either "divide by zero errors"

or an incorrect TVD when the borehole is a straight line but deviated.

1: North = SUM (MD2 - MD1) * (Cos WD1 - Cos WD2) * (Sin HAZ2 -

Sin HAZ1)

/ ((WD2 - WD1) * (HAZ2 - HAZ1))

2: East = SUM (MD2 - MD1) * (Cos WD1 - Cos WD2) * (Cos HAZ1 -

Cos HAZ2)

/ ((WD2 - WD1) * (HAZ2 - HAZ1)}

3: TVD = SUM (MD2 - MD1) * (Sin WD2 - Sin WD1) / (WD2 - WD1)

Minimum Curvature Method

Minimum Curvature Method

The minimum curvature method, like the radius of curvature method,

takes the space vectors defined by inclination and direction measurements

and smoothes these onto the wellbore curve by the use of a ratio

factor which is defined by the curvature (dog-leg) of the wellbore

section. The method produces a circular arc as does the radius

of the curvature. This is not, however, an assumption of the method,

but a result of minimizing the total curvature within the physical

constraints on a section of wellbore.

1: DL = Arccos (Cos (WD2 - WD1) - Sin WD1 * Sin WD2 * (1 - Cos

(HAZ2 - HAZ1)))

2: CF = 2 / DL * (Tan (DL / 2)) * 0.017 453

3: North = SUM ((MD2 - MD1)*((Sin WD1 * Cos HAZ1 + Sin WD2 * Cos

HAZ2) / 2) * CF)

4: East = SUM ((MD2 - MD1) * ((Sin WD1 * Sin HAZ1 + Sin WD2 *

Sin HAZ2) / 2) * CF)

5: TVD = SUM (((MD2 - MD1) * (Cos WD2 + Cos WD1) / 2) * CF)

Where:

DL = dog leg severity (degrees)

CF = curvature factor (radians)

The term 0.017 453

converts

degrees to radians.

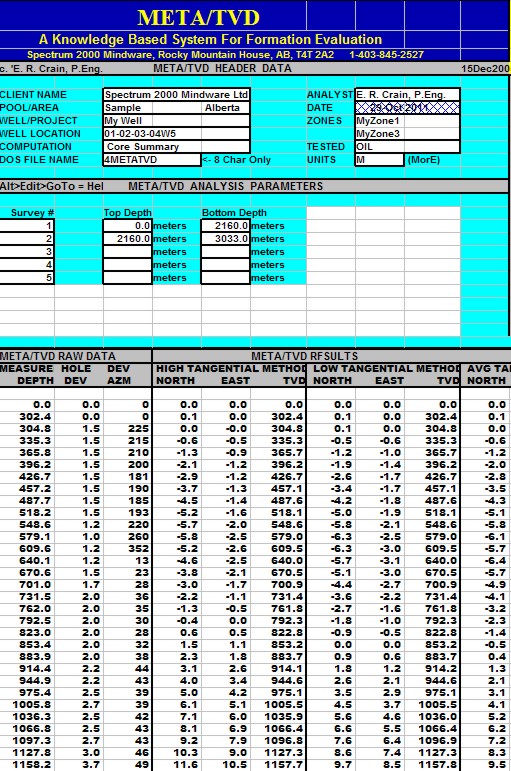

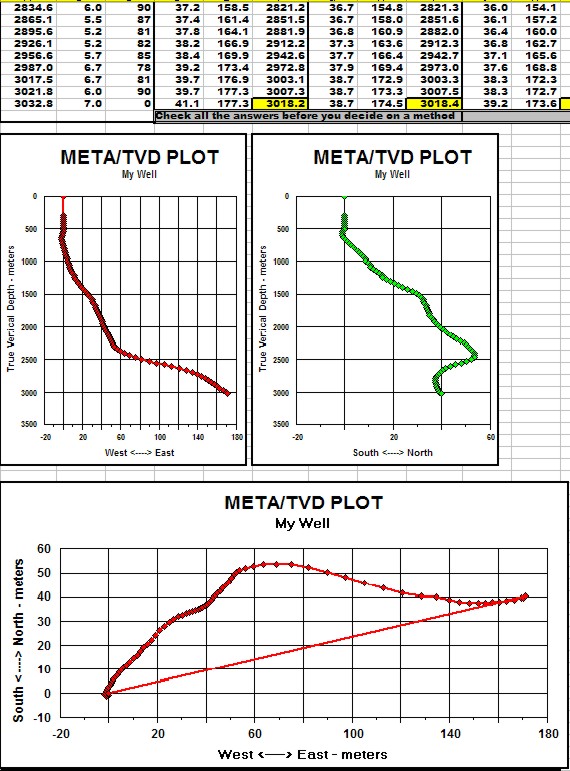

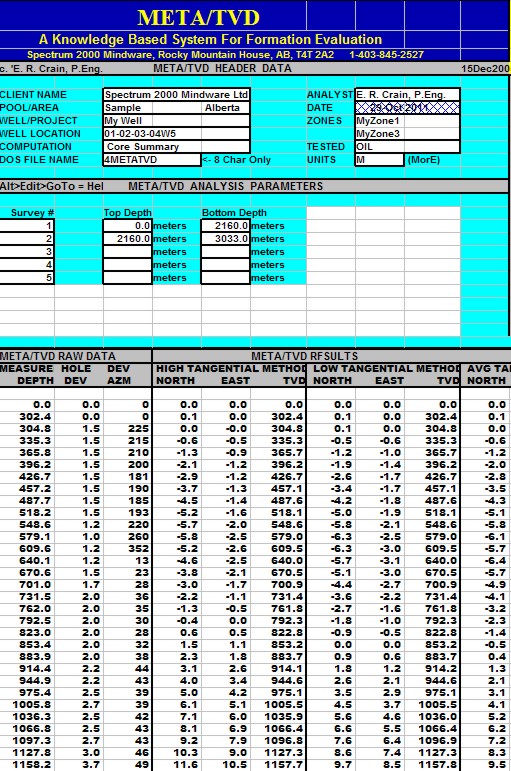

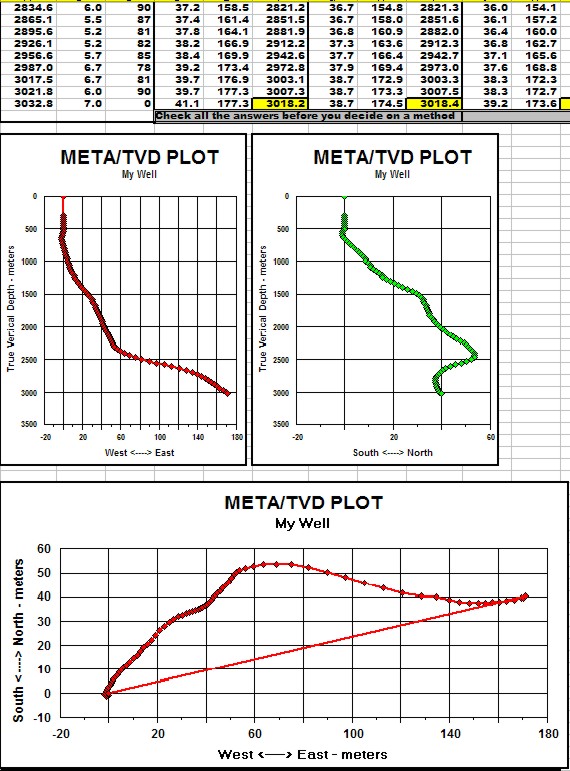

META/LOG

"TVD" SPREADSHEET -- True Vertical

Depth META/LOG

"TVD" SPREADSHEET -- True Vertical

Depth

This spreadsheet calculates True Vertical Depth

from seven common methods. The more exotic methods are more accurate

and there is no excuse for not using them, since the spreadsheet

does all the hard work.

SPR-23 META/LOG TRUE VERTICAL DEPTH (TVD) CALCULATOR

Calculate true vertical depth TVD, X aand Y coordinates,

7 methods.

///////

//////

///////

//////

/////// //////

Sample output from META/LOG "TVD" Spreadsheet -several more sets of

results are offscreen to the right.

|