|

Basic 3 - arm Continuous Dipmeter Calculations

Basic 3 - arm Continuous Dipmeter Calculations

This Section deals

with the 3 arm dipmeter calculations that were performed in

the early days of dipmeter logging. These tools are no

longer run but the dip data can be found in well files. To

use that information, it pays to know how the calculations

were made and their limitations.

The computation of

early dipmeter data has been handled in one of three

general ways: manual processing, combination of manual and computer

processing, and total computer processing.

Manual

correlation and computation methods were developed first and there

are several different methods of doing the work. The dipmeter

curves must first be correlated; this may be done by slipping

a print of a log under the film used to make the print and measuring

the depth displacement between peaks and valleys on the curves.

Pad number one is used as a reference to measure displacements

to each of the other curves.

Another

method of curve correlation uses an optical comparator, a system

of mirrors and lenses which allow the user to optically lay one

curve over another and shift it up and down. The amount of shift

is measured mechanically on a dial and is recorded as the displacement.

After

these correlations have been made, the azimuth of the number one

electrode, the borehole deviation angle, the relative bearing,

and the borehole diameter from the calipers are recorded. This

information, plus the depth, is necessary to compute the dip angle

and dip direction of a point referenced to magnetic north. Because

true dip is referenced to true north, we must also account for

magnetic declination of the region.

Mathematical

formulas to solve this geometric puzzle are given later in this

Chapter. The manual calculation of dip magnitude and direction

with the above information was made in several ways: by using

a calculator and trigonometric tables, a scientific programmable

calculator (after 1970) with trig functions, a mathematically

derived physical computing device (in other words, an analog computer),

or stereographic nets, the latter being the most common manual

method used in the past. A very small amount of hand calculator

work is still done today.

Another

method of dipmeter computation utilized manual correlation and

computer reduction of the data. This type of processing was originally

developed to minimize turnaround time and to allow the tedious,

time consuming computation and plotting of results to be performed

by a digital computer. This may still be done today for re-computation

of continuous dipmeters recorded on paper, or on 7 track digital

tapes (which are unreadable by most modern computers) for which

the paper records are still available.

The

most recently developed system of computation is computer correlation

and calculation from data on digital magnetic tape. The data from

the magnetic tape is entered into a digital computer and processed.

In the correlation program, the digital information representing

the dipmeter curves is stored in memory and the data from one

trace is compared to the other traces to determine the vertical

displacement between the traces. After these displacements are

calculated, the tool orientation information is used to compute

the actual formation dips.

The

standard correlation process is performed by a mathematical function

called cross-correlation, in which the offset distance between

events on two curves are found. The distance between the center

and the maximum amplitude on the correlagram indicates the displacement

between the two curves. The offsets for all curve pairs are then

adjusted to obtain the offsets relative to the center of the correlation

interval. More exotic forms of correlation, some based on pattern

recognition theory, are used in the newer programs.

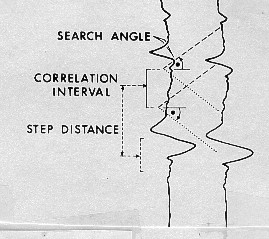

The

length of the portion of the curve being correlated is called

the correlation interval, correlation length, or correlation window.

Correlation interval is usually between one and four feet, but

can be smaller or larger. The correlation is calculated at regular

intervals along the log. The distance between correlations is

called the step distance and is usually 1/2 to 1/4 of the correlation

interval. One dip value is calculated at the center of each correlation

window, and the dip value is plotted at each step distance.

In

order to determine how far up and down each adjacent curve the

correlation is to be performed, a search angle is defined. In

moderate structural dip the search angle is usually 45 degrees,

but if expected dips are low, the angle can be reduced to

eliminate noise, or spurious dips caused by erratic wiggles on

the curves. Some computer programs use a search length instead

of a search angle. In steep dips, a higher search angle is

required. These terms are illustrated at the right. In

order to determine how far up and down each adjacent curve the

correlation is to be performed, a search angle is defined. In

moderate structural dip the search angle is usually 45 degrees,

but if expected dips are low, the angle can be reduced to

eliminate noise, or spurious dips caused by erratic wiggles on

the curves. Some computer programs use a search length instead

of a search angle. In steep dips, a higher search angle is

required. These terms are illustrated at the right.

Dipmeter computation definitions

The

number of dips computed from computer processed logs can be any

density required for a particular purpose. For structural analysis,

normal densities range from one computation every one or two feet

to one computation every ten feet. In those instances where additional

information is required, such as for stratigraphic analysis, points

as close as every few inches can be computed.

The

usual way to describe these parameters is in the form CORR x STEP

x ANGLE. For example a 4 x 1 x 45 process uses a 4 foot correlation,

a 1 foot step, with a 45 degree search angle. The recommended

defaults for dipmeter processing are:

Low

angle structural dip: 4 x 2 x 45 eg: normal or reverse faults,

folds

High

angle structural dip: 8 x 4 x 80 eg: overthrust faults, recumbent

folds

Sand

body stratigraphic dip: 2 x 1 x 30 eg: beach, bar, channel, drape

Complex

stratigraphic dip: 1 x 0.5 x 30 eg: submarine fan, scree slope,

turbidite

A

fourth parameter is sometimes used to indicate that the program

can search farther up the curve if no correlation is found. This

is shown as:

4 x 2 x 35 x 2

which allows the program to use a 70 degree search angle after

failing at 35 degrees.

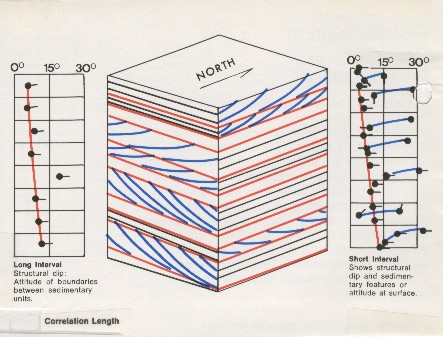

The

effect of a shorter correlation interval is shown below, where only regional dip is found in the long interval

case, and stratigraphic dip is superimposed on the regional when

a short interval is used.

Regional and stratigraphic dipmeter computation

using different correlation interval

The

problem with dip determination by cross-correlation is that it

does average all dips found in the correlation interval. If both

structural and stratigraphic dips are present, the average may

not reflect either of them correctly, regardless of the correlation

interval. Regional dip is therefore usually chosen in a nearby

shale or bedded carbonate thick enough to give an accurate result,

without interference from stratigraphic events.

Many

dipmeters have been computed with inappropriate parameters and

could be improved by re-computation with a better choice of values.

The defaults shown above are just starting points. In particular,

parameters for steeply deviated holes may need considerable experimentation

and variation throughout the hole.

To compute the displacements between the wiggles on a three curve

continuous dipmeter, we could correlate at each computation level,

defined by the correlation length, a segment of curve 1 with curve

2 first, and then correlate a segment of curve 2 with curve 3.

The two displacements found would be sufficient to determine the

dip. However, we might just as well have correlated curves 2 and

3 then curves 3 and 1, or curves 3 and 1 and then 1 and 2. All

three combinations of displacement pairs should in theory define

the same bedding plane, and the same dip. If they do not, a closure

error exists.

In

manual correlations, one could correlate three pairs, determining

three displacements. For perfect closure, the algebraic sum of

the displacements must be zero. Usually, because of the inaccuracy

of the optical comparator, a small closure error existed. This

error could then be distributed among the three displacements

as a small correction before final determination of the dip. In

practice, this was an onerous task, and two pairs were often picked

with no attempt to determine closure error.

In

automatic correlations, two kinds of closure errors can occur:

small ones due to minor variations in shape between the three

curves, and large errors. Small errors are handled as for manual

computation.

When

a large error exists, it is because at least one of the correlations

is in error - the same geological event is not being picked on

all three pairs. In manual correlation, a large error was usually

fixed by re-picking one of the correlated curves. For an automatic

computation, we have to choose between three possible computable

dips, only one of which may be correct. There are no strong mathematical

rules to choose the correct dip. If closure error is large, the

usual procedure is to compute no result and display no dip arrow.

The

three arm tool is also vulnerable to adverse hole conditions.

If one curve degenerates, for instance when one pad fails to make

a good contact with the borehole wall, the computation of dip

cannot be made at all. This happens often in deviated holes or

in out-of-round holes, resulting in more intervals with no result.

|