|

LAMINATED RESERVOIR basicS

LAMINATED RESERVOIR basicS

Porosity and water saturation in laminated shaly sands, and in other

cases of anisotropic reservoirs, are a special case, not amenable to

conventional petrophysical solutions. Isotropic reservoirs are those

in which the physical properties are the same regardless of the

direction of measurement. Anisotropic reservoirs have one or more

properties that vary with direction.

The best known anisotropic

property is resistivity, which can vary by a factor of 100 or more,

depending on whether the measurement is made parallel to the bedding

or perpendicular to it. This is the situation that exists in most

so-called "low resistivity pay zones". These are usually laminated

shaly sands but can also be sandstones or carbonates with thinly

bedded variations in porosity. In resistivity log analysis,

anisotropy is present when the bedding is thinner than the tool

resolution and is sometimes described as a "thin-bed" problem.

A core photo, roughly full

size, of a short interval of the Second

White Specks, a laminated

sand tight gas or tight oil play in Alberta. Some sand lenses are as

thin as a pencil line. A core photo, roughly full

size, of a short interval of the Second

White Specks, a laminated

sand tight gas or tight oil play in Alberta. Some sand lenses are as

thin as a pencil line.

Rocks of

this type are called transverse isotropic; there is little

horizontal anisotropy, so resistivity differs between only two axes

- vertical and horizontal. Channel sands with significant cross

bedding and other linear depositional features could be anisotropic

on all three axes. Rocks of

this type are called transverse isotropic; there is little

horizontal anisotropy, so resistivity differs between only two axes

- vertical and horizontal. Channel sands with significant cross

bedding and other linear depositional features could be anisotropic

on all three axes.

There

are no logs that measure resistivity in 3 orthogonal axes at the

same time. The newest induction logs measure horizontal and vertical

resistivity (directions relative to tool axis). Azimuthal laterologs

read in eight directions (perpendicular to the tool axis) and could

be used to look for horizontal anisotropy in semi-vertical wells.

A modern thin

bed log, called the TBRt by Baker Hughes

The

newest thin bed tool is described as a thin bed Rt tool. It is a

microlaterolog type of device with a bed resolution of 5 cm and a

depth of investigation between 30 and 50 cm (12 to 20 inches), about

2 to 3 times deeper than earlier microlaterologs. If invasion is

shallow, the resistivity approaches a deep resistivity measurement.

This is very useful in laminated shaly sands where the laminae are

relatively thick.

Thin bed Rt log used to shape final log analysis

Other

thin bed logging tools are the microlog, microlaterolog, proximity

log, and micro spherically focused log. These tools measure 3 to 12

centimeters of rock but have a depth of investigation of similar

dimensions. In some laminated sands, these tools can be used to

determine net to gross sand ratio.

The electromagnetic propagation log measures in the

order of 6 cm but it is a porosity and shale indicator tool, not a

deep resistivity tool. Some sonic logs can be run with a 15 cm (6

inch) bed resolution.

Example of conventional resistivity and density neutron log in

laminated porosity, with microlog showing numerous very thin tight

streaks. Positive separation between the two microlog curves shows

porous intervals.

The

resistivity microscanner can see beds as thin as 0.5 cm and

fractures as thin as 1 micron. The acoustic televiewer can resolve

beds to 1 or 2 cm. Accurate net to gross ratios can be determined,

but again the resistivity of the sand fraction beyond the invaded

zone cannot be determined from these tools.

Resistivity microscanner log in a

laminated shaly sand.

None of

the tools listed above provide a useful deep resistivity value when

laminations are thinner than the tool resolution, so unconventional

log analysis models are needed.

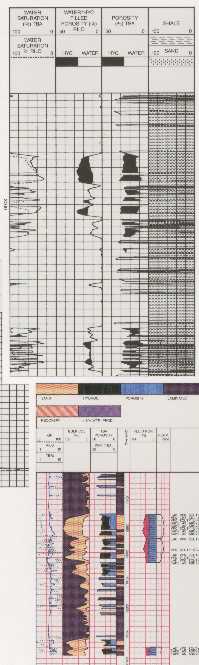

While

laminated shaly sands are best known, laminated porosity is also a

problem for log analysts. The Bakken and Montney reservoirs in

Canada are good examples. The illustrations below give a clear

example of how porosity logs and analysis results smooth out the

porosity variations, which in turn smooth out the saturation and

permeability answers. The latter is especially critical, since

productivity estimates for laminated reservoirs can be seriously

under-estimated because the high permeability streaks tend to be

ignored.

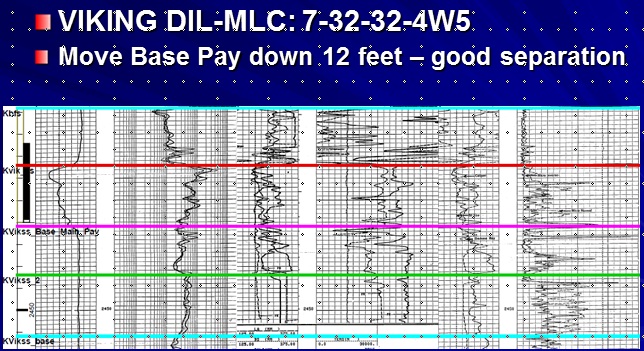

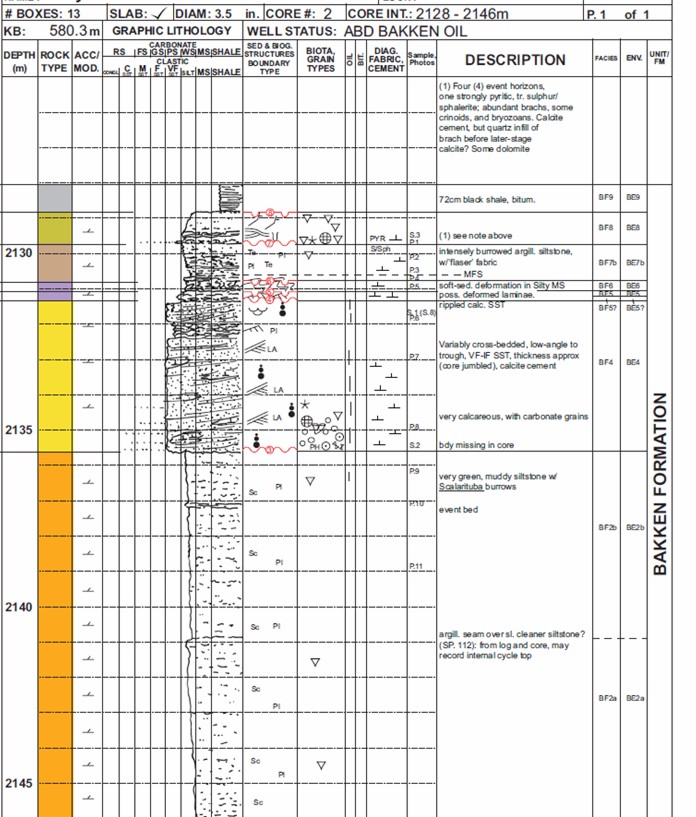

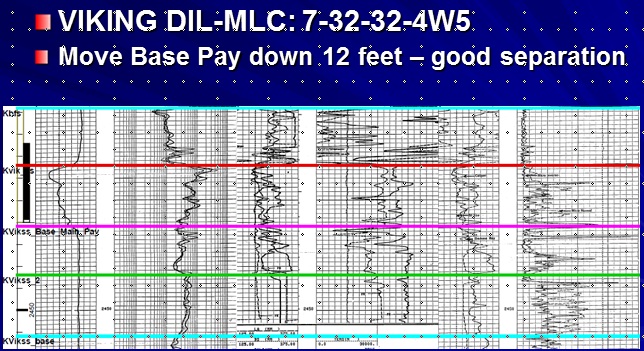

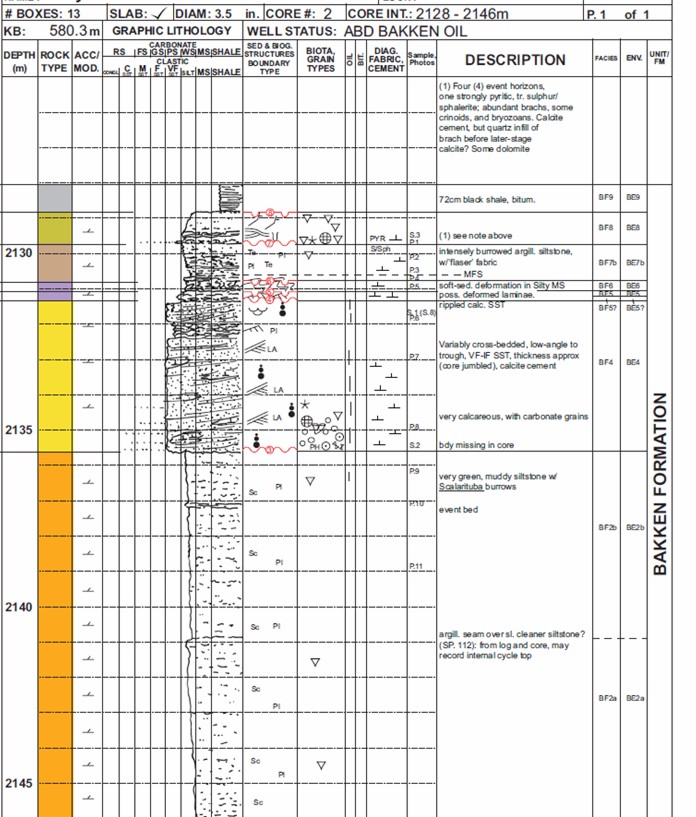

Core description log in a laminated Bakken sand. Upper half of

interval is highly laminated, lower half has thicker beds. See plot

of core data below. (Illustration courtesy Graham Davies Geological

Consultanting)

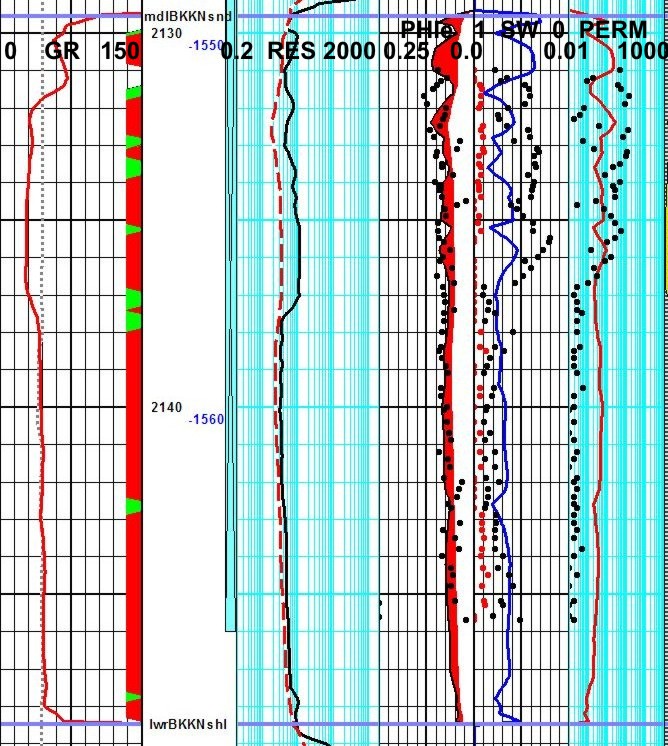

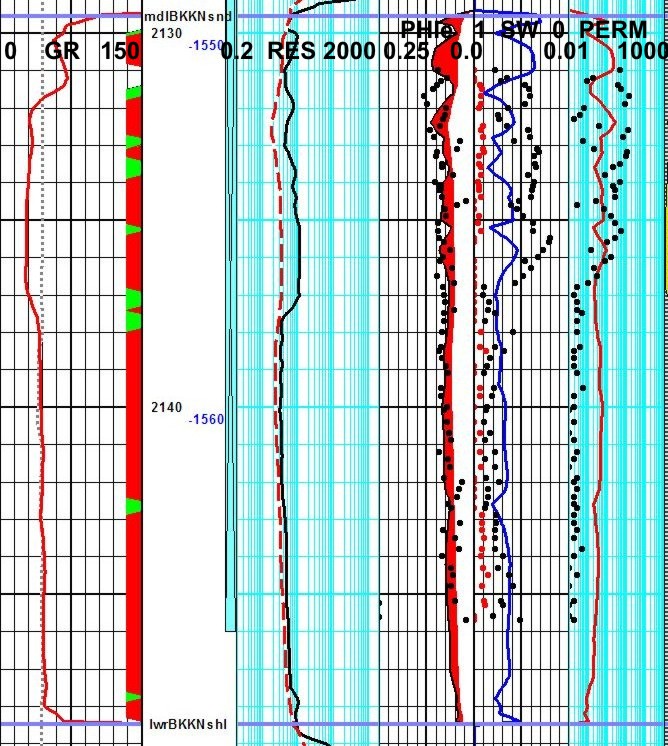

Closely spaced core samples demonstrate laminated nature of Bakken

sand, compared to the running average created by well logs. Distinct

coarsening upward and fining upward sequences can be seen in the

upper half of core (grid lines are 1 meter). The lower half of the

cored interval is less laminated, so porosity and permeability

variations are smaller. Longer running average on resistivity log

makes water saturation even more difficult to assess and comparison

to core is worse than for porosity and permeability

Logs and core are for same well as core description shown above.

Resistivity in Anisotropic Reservoirs

Resistivity in Anisotropic Reservoirs

The problem lies in how resistivity logs average laminations that

are thinner than the tool resolution. Most logs average the data in

a linear, thickness weighted fashion, but induction and laterologs

average conductivity and then convert it to resistivity. In shaly

sands, the conductivity of the shale laminations is usually much

higher than the gas or oil sand laminations, the resulting

conductivity is high (low resistivity). This makes the zone look

like a poor quality reservoir, maybe so poor that it will not be

tested, thus bypassing considerable oil or gas.

The

physical model for a laminated shaly sand compared to a clean sand

and conventional shaly sands. The high conductivity of the shale

lamination (black shading) strongly influences the net conductivity

measured by resistivity tools. The

physical model for a laminated shaly sand compared to a clean sand

and conventional shaly sands. The high conductivity of the shale

lamination (black shading) strongly influences the net conductivity

measured by resistivity tools.

A

similar problem exists in laminated porosity. The low porosity

laminations have higher water saturation than oil or gas bearing

higher porosity laminations. The measured resistivity of the

laminated hydrocarbon bearing reservoir is often close to the truth,

but the calculated water saturation of water zones may be

misleading.

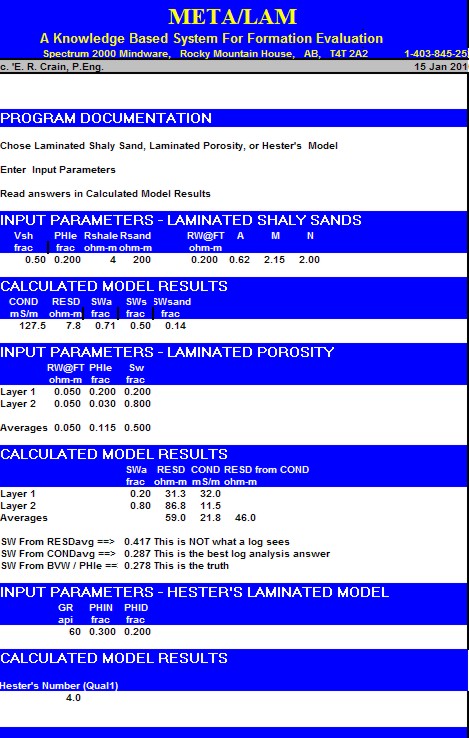

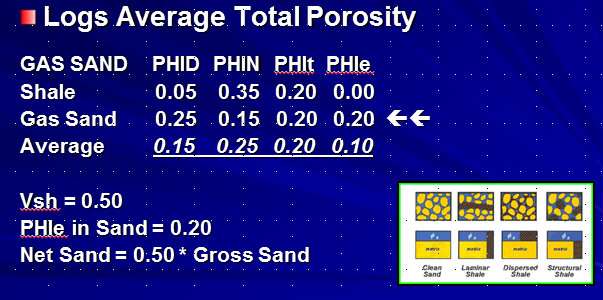

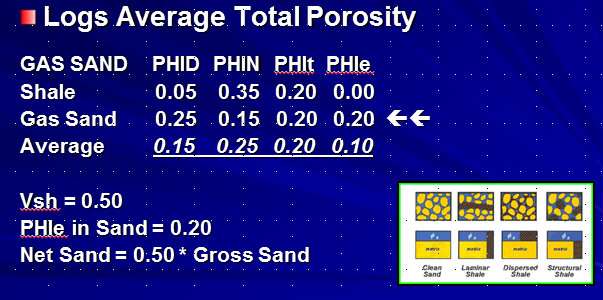

To

illustrate the simplest case, assume a laminated shaly sand sequence

with shale laminations equal in thickness to the sand laminations.

This gives a shale volume (Vsh) averaged over the interval of 50%.

Assume the porosity and resistivity values are as shown at the

right. To

illustrate the simplest case, assume a laminated shaly sand sequence

with shale laminations equal in thickness to the sand laminations.

This gives a shale volume (Vsh) averaged over the interval of 50%.

Assume the porosity and resistivity values are as shown at the

right.

The average total porosity in this example is 0.20; the average

effective porosity is only 0.10 – that’s what the density neutron

logs see. The actual porosity in the sand fraction is 0.20 but

conventional log analysis cannot tell us that.

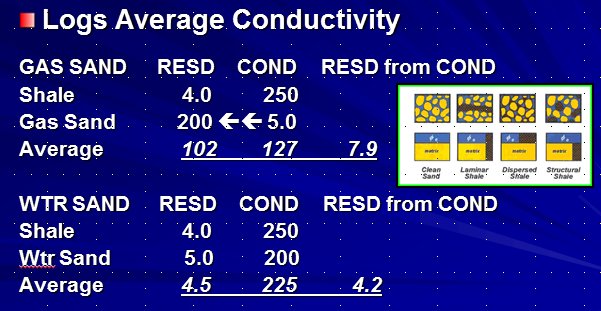

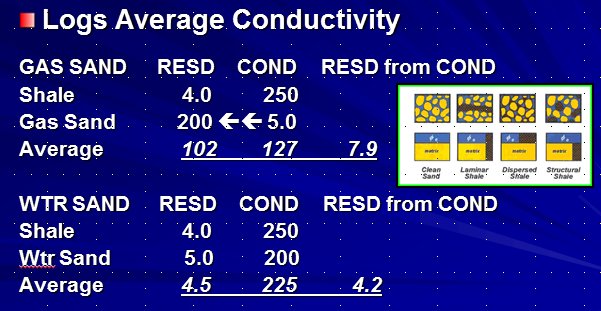

The

effect of laminations on resistivity is even more serious because

the logs really measure conductivity, not resistivity. Again

assuming a 50:50 mix of sand and shale laminations, the average

conductivity in the illustration at the left is 127 mS, which

translates to 7.9 ohm-m. The

effect of laminations on resistivity is even more serious because

the logs really measure conductivity, not resistivity. Again

assuming a 50:50 mix of sand and shale laminations, the average

conductivity in the illustration at the left is 127 mS, which

translates to 7.9 ohm-m.

SO: the average of 4 ohm-m and 200 ohm-m is a little less than 8

ohm-m - pretty scary, but that is what real induction and laterologs

do!

To get a good answer for water saturation using an Archie type

method, you need to use the 200 ohm-m of the sand fraction (not the

measured value of 7.9) with the sand fraction porosity of 0.20 (not

the measured value of 0.10).

The lower part of the previous illustration shows the calculation

for a laminated water sand. The error in measured resistivity is

small, but the resistivity contrast between a water zone and a

hydrocarbon zone is small – less than 2:1. The rule of thumb for

detecting hydrocarbons is usually 3:1 or more.

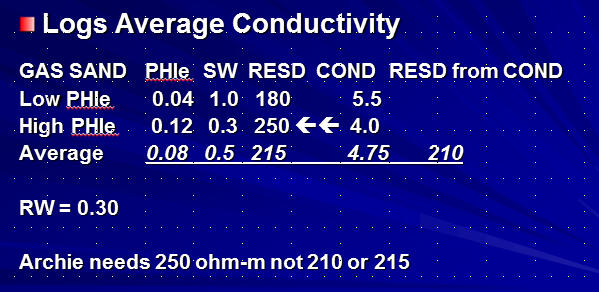

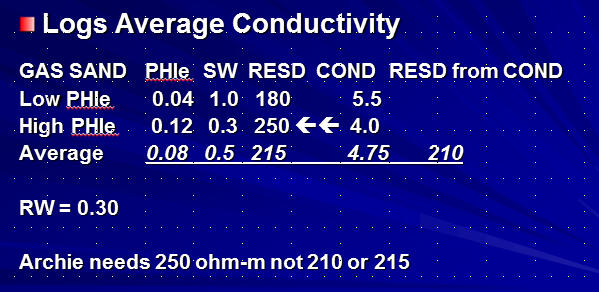

The

case of laminated porosity is slightly different. The resistivity

contrasts are smaller than the laminated shaly sand case. The

resistivity of the higher porosity streaks with low water saturation

may be close to that of the low porosity streak with higher water

saturation. But water zones may look pretty resistive, again giving

misleading water saturation. The

case of laminated porosity is slightly different. The resistivity

contrasts are smaller than the laminated shaly sand case. The

resistivity of the higher porosity streaks with low water saturation

may be close to that of the low porosity streak with higher water

saturation. But water zones may look pretty resistive, again giving

misleading water saturation.

In this example, the measured resistivity for a 50:50 mix of 4 and

8% porosity laminations in a clean sand is 210 ohm-m, very close to

the average of the resistivity values assumed for the two rock

types. However, we need to use the 250 ohm-m resistivity of the good

quality sand for the saturation calculation, along with the 0.12

porosity to understand the quality of the reservoir. Using the

average resistivige and porosity seen by logs will be very

misleading.

Modeling laminated shaly sands or laminated porosity with a

spreadsheet is the only way to understand the resistivity response

and resulting water saturation – usually counter-intuitive, always

surprising. A spreadsheet for these models is available as a free

download on my website at

www.spec2000.net

.

3-D Induction logs

3-D Induction logs

Some

newer induction logging tools provide a vertical conductivity

measurement as well as the usual horizontal measurement. If the beds

are still parallel to the horizontal induction log signal, the

vertical induction signal will give an average of the resistivity of

the beds instead of averaging the conductivity. This is because the

normal induction averages the beds in a parallel electrical circuit

and the vertical induction sees a series circuit.

Assume a

laminated shaly sand with horizontal bedding, a vertical borehole,

and a logging tool that can measure both vertical and horizontal

conductivity:

1. CONDhorz = VSHavg

* CONDshale + (1 - VSHavg) * CONDsand

2. RESvert = VSHavg *

RESshale + (1 - VSHavg) * RESsand

3. REShorz = 1000 /

CONDhorz

4. CONDvert = 1000 /

RESvert

5. AnisRatio =

RESvert / REShorz

OR 5. AnisRatio = CONDhorz /

CONDvert

6. AnisCoef = AnisRatio ^ 0.5

Where:

AnisRatio = anisotropic

ratio

AnisCoef = anisotropic coefficient

CONDhorz = horizontal conductivity (mS/m)

CONDvert

= vertical conductivity (mS/m)

CONDsand = sand lamination

conductivity (mS/m)

CONDshale = shale

lamination conductivity (mS/m)

REShorz = horizontal resistivity (ohm-m)

RESvert

= vertical resistivity

(ohm-m)

RESsand = sand lamination

resistivity (ohm-m)

RESshale = shale

lamination resistivity (ohm-m)

VSHavg = shale lamination volume within the interval measured by

the logging tool (fractional)

Equations 5 and 6 are as defined by Schlumberger in 1934. Some

authors invert the equations so the coefficient is less than or

equal to 1.0.

Equations 1 and 2 can be solved simultaneously for any two unknowns

if the other parameters are known or computable. For example, we can

solve for RESsand and RESshale if RESvert and REShorz are measured

log values and VSHavg is computed from (say) the gamma ray log over

an interval. Alternatively, we can solve for RESsand and VSHavg if

we assume RESshale = RSH from a nearby thick shale:

8. CONDsand = CONDvert * (CONDshale - CONDhorz) / (CONDshl - CONDvert)

9. VSHavg = (CONDhorz - CONDsand) / (CONDshale - CONDsand)

If you

prefer to think in Resistivity terms:

10.

RESsand = REShorz * (RESvert - RESshale) / (REShorz - RESshl)

11.

VSHavg = (RESsand - RESvert) / (RESsand - RESshale)

RESsand

is then used in Archie's water saturation equation, along with

porosity from core or from a laminated sand porosity method, for

example:

12: PHINsand = (PHIN - VSHavg * PHINSH) / (1 - VSHavg)

13: PHIDsand = (PHID

- VSHavg * PHIDSH) / (1 - VSHavg)

14: PHIsand = (PHINsand

+ PHIDsand) / 2

15: SWsand = (A * RW@FT / ((PHIsand^M) * RESsand))^(1/N)

Where:

PHINsand = neutron porosity of a sand lamination

PHIN = neutron log reading in the laminated sand

PHINSH = neutron shale value in a nearby thick shale

PHIDsand = density

porosity of a sand lamination

PHID = density log reading in the laminated sand

PHIDSH = density shale value in a nearby thick shale

PHIsand = effective

porosity of a sand lamination

SWsand = effective water

saturation of a sand lamination

RW@FT = water resistivity at formation temperature (ohm-m)

A, M, and N = electrical properties of a sand lamination

Equations 10 through 15 can be plotted versus depth, but this may be

misleading since only some of the interval has the porosity and

water saturation that is displayed – some of the reservoir interval

is nearly pure shale. Oil or gas in place must be adjusted by the

net to gross ratio based on the average shale volume:

16: Net2Gross = (1 – VSHavg)

17: NetSand = (1 –

VSHavg) * GrossSand

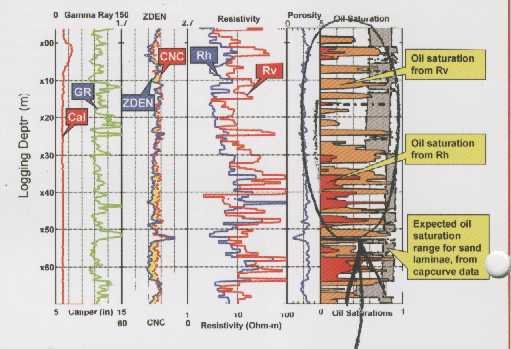

Vertical

resistivity logs are still very rare, but are the tool of choice for

laminated shaly sands. An example is shown below. Notice the large

difference between Rv and Rh on the raw log and the difference in Sw

on the computed log.

Example of vertical and horizontal resistivity

in laminated shaly sand

3-D

Induction logs IN DIPPING BEDS

3-D

Induction logs IN DIPPING BEDS

The example given above involved a laminated shaly

sand with bedding perpendicular to the borehole axis (horizontal

bedding, vertical borehole). When beds dip relative to the

borehole, the situation becomes more complicated. The relative

dip is the important factor and takes a bit of thought when the

borehole is not vertical.

Dipmeter

results are presented as true dip angle and direction relative to a

horizontal plane and true north. To obtain dip and direction of beds

relative to a logging tool in a deviated borehole, you need the

borehole deviation and direction from a deviation survey. This is

often obtained at the same time as the dipmeter, but may come from

some other deviation survey, either continuous or station by

station. You need to rotate the true dips into the plane

perpendicular to the borehole to get the final relative dip.

For a

conventional induction log, the apparent conductivity is:

18. CONDlog = ((CONDhorz * cos(RelDip))^2 + CONDvert * CONDhorz * (sin(RelDip))^2)^0.5

Where:

CONDlog = conductivity measured by a log in an anisotropic rock (mS/m)

ReLDip = formation dip angle relative to tool axis

When

relative dip is 0 degrees (horizontal bed, vertical wellbore), the

conventional log reads CONDhorz, as we know it should. However, if

relative dip is 90 degrees, as in a horizontal hole in horizontal

laminated sands, the log reading is (CONDhorz * CONDvert) ^0.5. This

is a surprise, as we might have expected the tool to measure

CONDvert.

If two

deviated wells are logged through the same formation (at

considerably different deviation angles), two equations of the form

of equation 18 can be formulated and solved for CONDhorz and

CONDvert. RESsand and VSHavg can then be calculated as in equations

10 and 11.

AlternAte MODELS – Laminated Shaly SandS

AlternAte MODELS – Laminated Shaly SandS

In the absence of a vertical resistivity measurement, we can

make some assumptions and use a non-conventional analysis model.

These models do not generate log curves that can be plotted versus

depth. Instead, they look at stratigraphically significant layers

and generate the average properties for each layer.

MODEL 1: An

obvious solution is to use the math for the vertical resistivity

model (equations 10 through 17 given earlier) with assumed values of RESsand (based on a model of a clean sand) and Vsh (based on the GR

log). The results would give an indication of the reservoir quality

of the individual layer analyzed. Permeability, pore volume (PV),

hydrocarbon pore volume (HPV), and flow capacity (KH) are calculated

from the above results, just as for conventional sands, bearing in

mind that the results apply only to the NetSand portion of the gross

interval. No depth plot would be available as the results apply to

the whole layer.

MODEL 1: An

obvious solution is to use the math for the vertical resistivity

model (equations 10 through 17 given earlier) with assumed values of RESsand (based on a model of a clean sand) and Vsh (based on the GR

log). The results would give an indication of the reservoir quality

of the individual layer analyzed. Permeability, pore volume (PV),

hydrocarbon pore volume (HPV), and flow capacity (KH) are calculated

from the above results, just as for conventional sands, bearing in

mind that the results apply only to the NetSand portion of the gross

interval. No depth plot would be available as the results apply to

the whole layer.

MODEL

2: Another model uses rules for

finding the rock properties based on shale volume, along with

constants derived from core analysis. These empirical rules can be

calibrated to core and then used where there is no core data. The PHIMAX porosity equation and Buckles water saturation equation given

below are widely used in normal shaly sands where the log suite is

at a minimum, and are equally useful in the laminated case:

MODEL

2: Another model uses rules for

finding the rock properties based on shale volume, along with

constants derived from core analysis. These empirical rules can be

calibrated to core and then used where there is no core data. The PHIMAX porosity equation and Buckles water saturation equation given

below are widely used in normal shaly sands where the log suite is

at a minimum, and are equally useful in the laminated case:

18: VSHavg = average Vsh from GR or density neutron separation over the

layer’s gross interval

19: Net2Gross = (1 - VSHavg) or from core, televiewer, or microscanner

20: NetSand = (1 - VSHavg) * Gross

21: PHIsand = PHIMAX

22: SWsand = KBUCKL / PHIsand

OR 22: SWsand = (A * RW@FT / ((PHIsand^M) * RESsand))^(1/N)

Where:

PHIMAX = maximum porosity expected in the clean sand laminations

KBUCKL = Buckle’s number, product of porosity times water

saturation expected in a clean sand lamination

This model

presupposes that the laminated sand is hydrocarbon bearing. Again,

permeability, pore volume (PV), hydrocarbon pore volume (HPV), and

flow capacity (KH) are calculated from the above results, just as

for conventional sands, bearing in mind that the results apply only

to the NetSand portion of the gross interval.

The

PHIMAX value is the critical factor. If a moderate amount of core

data is available for the sand fraction of the laminated sand, this

data can be mapped and used to control PHIMAX spatially. RESsand can

be assumed from a nearby clean hydrocarbon bearing sand or by

inverting the Archie equation with reasonable values of PHIMAX, RW@FT,

and SW. KBUCKL is usually in the range 0.035 to 0.060, varying

inversely with grain size of the clean sand fraction.

A very

minimum log suite can be used, since the only curve required is a

gamma ray shale indicator, but only if there are no radioactive

elements other than clay. This is not the case in the Milk River, so

a minimum log suite will not work here. We have used the minimum

suite successfully in laminated shaly sands in Lake Maracaibo.

MODEL

3: This model uses the linear log

response equation to back-out the clean sand fraction properties

from the actual log readings and the shale properties. The response

equations are used on the average of the log curves over the gross

sand interval. We still assume:

MODEL

3: This model uses the linear log

response equation to back-out the clean sand fraction properties

from the actual log readings and the shale properties. The response

equations are used on the average of the log curves over the gross

sand interval. We still assume:

23: VSHavg = average Vsh from GR or density neutron separation over gross

interval

24: Net2Gross = (1 - VSHavg) or from core, televiewer, or microscanner

25: NetSand = Gross * Net2Gross

26: PHINsand = (PHINavg – VSHavg * PHINSH) / (1 - VSHavg)

27: PHIDsand = (PHIDavg – VSHavg * PHIDSH) / (1 - VSHavg)

28: PHIsand = (PHINsand + PHIDsand) / 2

29: CONDsand = (CONDavg – VSHavg * 1000 / RESshale) / (1 - VSHavg)

30: RESDsand = 1000 / CONDsand

31: SWsand = KBUCKL / PHIsand

OR 31: SWsand = (A * RW@FT /

((PHIsand^M) * RESDsand))^(1/N)

Where:

XXXXavg = log value averaged over a discreet laminated sand

interval, thicker than the tool resolution

This

model has the advantage of using fewer arbitrary rules and more log

data, including resistivity log data. The critical values are

RESshale, PHINSH, and PHIDSH, which are picked by observation of the

log above the zone. It can still be calibrated to core by adjusting

these parameters. If the Archie water saturation equation is used,

it might distinguish hydrocarbon from water. The Buckle’s saturation

presupposes hydrocarbons are present.

The

layer average PHIDsand and PHINsand can be compared to each other to

see if they are similar values – they should be if the parameters

are reasonably correct. They could cross over if gas effect is

strong enough. Our results showed a 0.02 porosity unit variation on

the best behaved wells, indicating that the inversion of the

response equations was working well. However, on some intervals in

some wells, the results were not nearly so good.

Reservoir Quality Indicators frOM Laminated Shaly Sand MODELS

Reservoir Quality Indicators frOM Laminated Shaly Sand MODELS

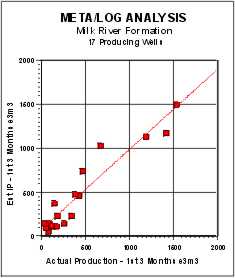

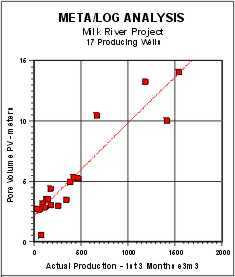

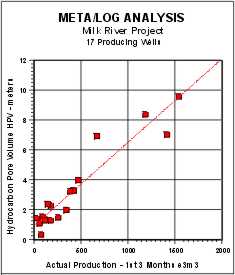

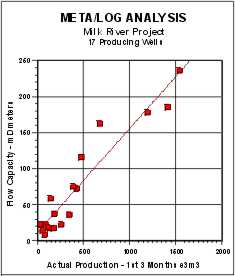

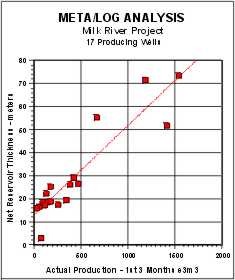

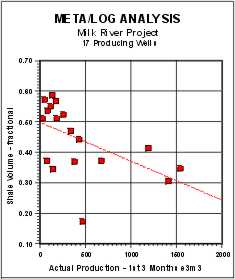

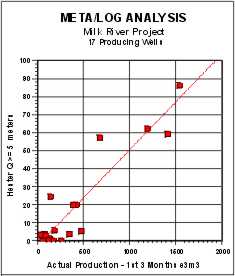

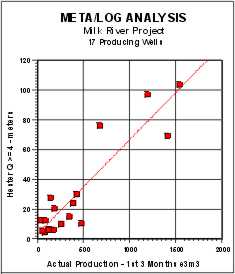

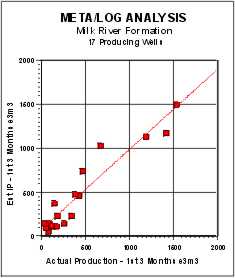

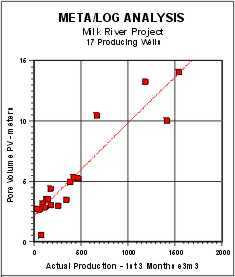

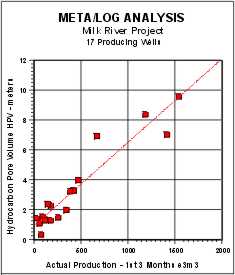

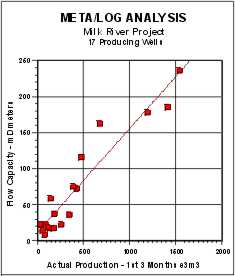

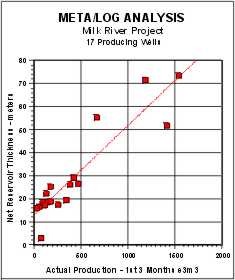

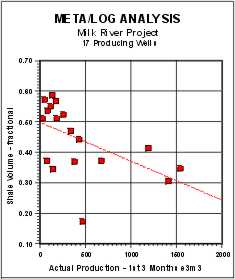

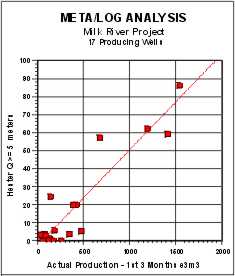

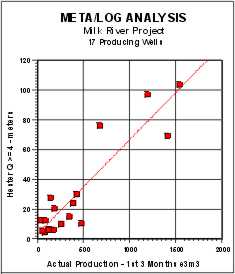

There are a number of

ways to assess reservoir quality. In laminated sands. One approach

is to correlate first three months or first year production with net

reservoir properties from one of the laminated models described

above. The following example used Model 3 and is from “Productivity

Estimation in the Milk River Laminated Shaly Sand, Southeast Alberta

and Southwest Saskatchewan” by E. R. (Ross) Crain and, D.W. (Dave)

Hume, CWLS Insite, Dec 2004.

We chose

to use the first 8760 hours of production (365 days at 24 hours

each) divided by 4 (3 months of continuous production) as our

“actual” production figure. This normalizes the effects of testing

and remedial activities that might interrupt normal production.

The

normalized initial production was correlated with net reservoir

thickness, pore volume (PV), hydrocarbon pore volume (HPV), and flow

capacity (KH). Correlation coefficients (R-squared) are 0.852,

0.876, 0.903, and 0.906 respectively. The correlation is made using

data calculated over the total perforated interval. Average shale

volume was correlated with actual production but the correlation

coefficient was only 0.296, although the trend of the data is quite

clear. Correlation of actual production versus the various reservoir

properties are shown below.

Productivity estimate based on Model 3 results and a log analysis

version of the productivity equation can be used as well. The

equation is:

32. ProdEst = 6.1*10E-6 * KH * ((PF - PS)^2) / (TF + 273) * FR * 90

Where:

KH = flow capacity (md-meters)

(PF - PS) = difference between formation pressure and surface

back-pressure (KPa)

TF = formation temperature (degrees Celsius)

FR = hydraulic fracture multiplier (usually 2.0 to 5.0)

The leading constant takes into account borehole radius, drainage

radius, and units conversions, and the constant 90 converts e3m3/day

into an estimated 3-month production for comparison to actual. A

correlation between estimated and actual 90 day production is shown

below, top right. Note that the equation used is a constant scaling

of KH, so the correlation coefficient is the same as the KH graph at

0.906.

|

Estimated Productivity vs Actual Initial 90 Day

Production |

Pore Volume (PV) vs Actual Initial 90 Day Production |

|

Hydrocarbon Pore Volume (HPV) vs Actual Initial 90 Day

Production |

Flow Capacity (KH) vs Actual Initial 90 Day Production |

|

Net Sand vs Actual Initial

90 Day Production |

Shale Volume (Vsh) vs Actual Initial 90 Day Production |

Because a full log suite was available in the 9 wells used for

calibration, we have obtained the most likely shale volume (VSHavg)

result. The 8 wells held in reserve to test the model also showed

very good agreement with initial production. One well that

calculated an IP higher than actual can be brought into line with a

small tune-up of the shale density parameter.

Reservoir Quality from an Enhanced Shale Indicator

Reservoir Quality from an Enhanced Shale Indicator

Another approach to assessing laminated shaly sands is to generate

reservoir quality curves that can be plotted versus depth, to assist

in choosing perforation intervals. One such curve is an enhanced GR

modified by the resistivity contrast between reservoir and shale

values:

33. QualGR = RSH * GR / RESD

Where:

QualGR = enhanced gamma ray quality indicator (API units)

RSH = resistivity of a nearby thick shale (ohm-m)

GR = gamma ray log reading (API units)

RESD = deep resistivity log reading (ohm-m)

This

amplifies the shale indicator in cleaner zones (higher net sand) and

is scaled the same as the GR curve. A net reservoir cutoff of QualGR

<= 50 on this curve was a rough indicator of first three months

production, but the correlation coefficient was as poor as for

average shale volume. The QualFR cutoff varies from place to place

and can be as high as 100 or more. QUALGR does make a useful curve

on a depth plot as it shows the best places to perforate when

density and neutron data are missing.

Reservoir Quality from Hester’s Number

Reservoir Quality from Hester’s Number

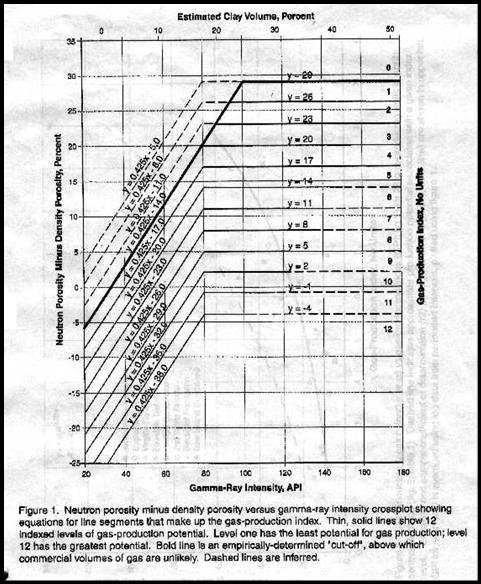

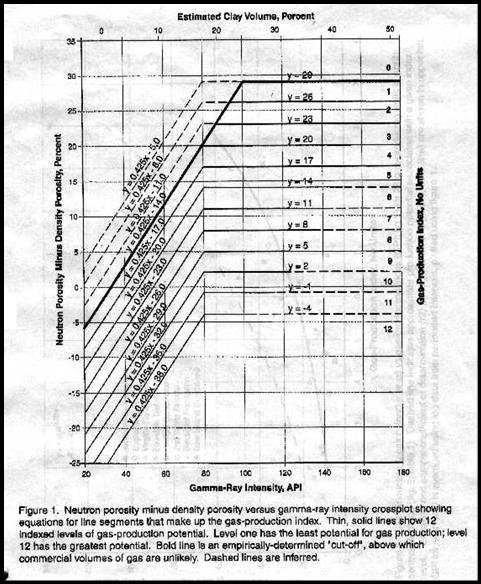

Another quality indicator was proposed in

“An

Algorithm for Estimating Gas Production Potential Using Digital Well

Log Data, Cretaceous of North Montana”, USGS Open File Report 01-12,

by T. C. Hester, 1999. It

related neutron-density porosity separation and gamma ray response

to production, based on the graph in below.

Hester’s reservoir quality

indicator (Qual1)

This

graph is converted to a numerical quality indicator (Qual1) in a

complex series of equations that represents predicted flow rate. An

Excel and Lotus 1-2-3 spreadsheet for solving this graph is

available free on my website at

www.spec2000.net . The equations, as

displayed in the Lotus 1-2-3 spreadsheet are as follows:

1: ND_DN

= 100 * (PHIN - PHID)

2: E = @IF(ND_DN>(0.425*GR)-14,0,@IF(ND_DN>(0.425*GR)-17,4,

@IF(ND_DN>(0.425*GR)-20,5,@IF(ND_DN>(0.425*GR)-23,6,

@IF(ND_DN>(0.425*GR)-26,7,@IF(ND_DN>(0.425*GR)-29,8,

@IF(ND_DN>(0.425*GR)-32,9,@IF(ND-DN>(0.425*GR)-35,10,11))))))))

3: F = @IF(ND_DN>(0.425*GR)-35,0,@IF(ND_DN>(0.425*GR)-38,11,12))

4: G = @IF(ND_DN>(0.425*GR)-14,0,@IF(ND_DN>29,0,

@IF(ND_DN>26,1,@IF(ND_DN>23,2,@IF(ND_DN>20,3,

@IF(ND_DN>17,4,@IF(ND_DN>14,5,0)))))))

5: H = @IF(ND_DN>14,0,@IF(ND_DN>11,6,@IF(ND_DN>8,7,@IF(ND_DN>5,8,

@IF(ND_DN>2,9,@IF(ND_DN>-1,10,@IF(ND_DN>-4,11,12)))))))

6: I = @IF(E=0,F,E)

7: J = @IF(G=0,H,G)

8: QUAL1 = @IF(GR<80,I,J)

Where:

ND_DN = neutron minus

density porosity difference in sandstone units (fractional)

PHID = density porosity

sandstone units (fractional)

PHIN = neutron porosity

sandstone units (fractional)

GR = gamma ray (API units)

Qual1 = Hester Quality

Number (unitless)

E, F, G, H, I, J =

intermediate terms

Note

that these nested IF statements are slightly different than those

originally published by Hester. The changes correct for

typographical errors in the original paper.

Hester’s

paper only looked at the average quality of a laminated reservoir

and did not consider the thickness of a particular quality level. To

overcome this, we can use a quality cutoff and obtain a thickness

weighted quality and correlate this to actual production, similar to

a net pay flag using porosity and saturation cutoffs:

9: IF Qual1 >= X

10: THEN PayFlagQ1 = “ON”

11: AND PayQ1 = PayQ1 + INCR

Where:

X = 4.0 or 5.0

PayQ1 = accumulated pay thickness based on Qual1>= X

A Hester

quality of 4.0 or higher reflects reservoir rock that is worth

perforating, and gives similar net reservoir thickness as the

previous indicators. Graphs showing the correlation of actual

production to net reservoir with Qual1 >=5 and >=4 are shown below.

The regression coefficients are 0.856 and 0.837 respectively.

Although this looks pretty good, the low rate data is clustered very

badly and other indicators work better in low rate wells. Some of

these wells were not perforated optimally and the Qual1 pay flag is

helpful for workover planning.

|

Hester Number (Q1 >=5) vs Actual Initial 90 Day

Production |

Hester Number (Q1 >=4) vs Actual Initial 90 Day

Production |

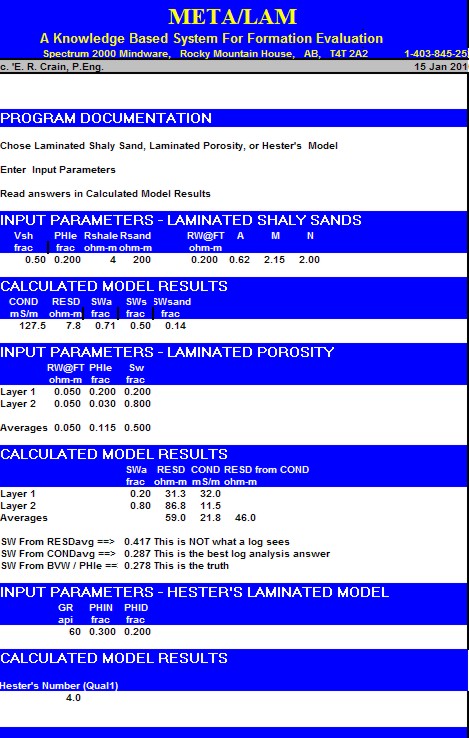

METALOG "/LAM"

SPREADSHEET -- LAMINATED SHALY SAND MODELS

METALOG "/LAM"

SPREADSHEET -- LAMINATED SHALY SAND MODELS

This

spreadsheet calculates laminated shaly sand and laminated porosity

models to see the effect of different assumptions on the net

resistivity of the interval. It also performs the Hester reservoir

quality calculation on individual data points to help assess the

best intervals to perforate.

SPR-16 META/LOG LAMINATED SAND CALCULATOR

Model laminated shaly sands

and laminated porosity.

Sample output from "META/LAM" spreadsheet for

laminated shaly sandstone.

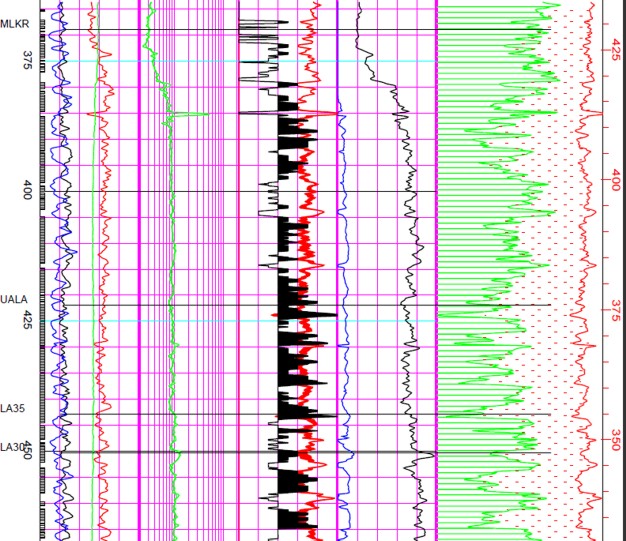

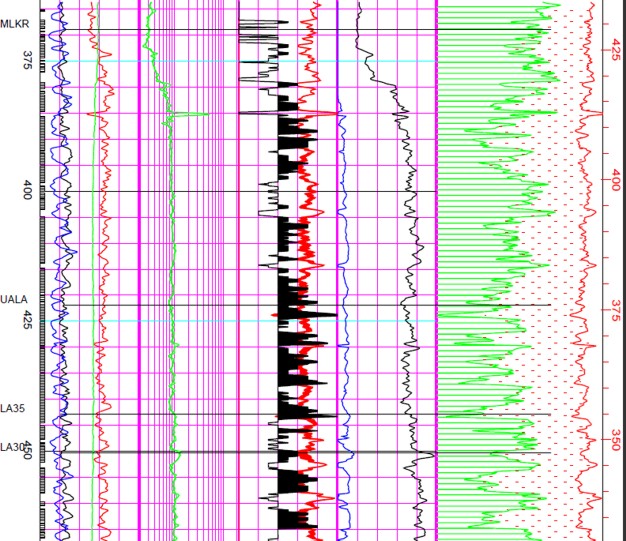

LAMINATED SAND EXAMPLE

LAMINATED SAND EXAMPLE

Depth plot showing Hester

quality factor in Track 3, shaded black where Qual1 >= 4. Zones with

Qual1 >= 5 are worth perforating in this area. Enhanced GR quality

curve (labeled Qual_2 here) is shown in Track 4. Values of QualGR <=

100 show better quality rock. This is a good well, so nearly all the

interval passes these cutoffs. The balance of the analysis is from a

conventional shaly sand analysis. Porosity and gas bulk volume (red

shading in Track 3) show the best intervals to perforate, but the

actual values do not represent the reservoir properties.

Laminated shaly sand example showing poorer quality interval with

Qual1 less than 5 that are not worth perforating. Scales and header

information are the same as the previous illustration.

|

The

effect of laminations on resistivity is even more serious because

the logs really measure conductivity, not resistivity. Again

assuming a 50:50 mix of sand and shale laminations, the average

conductivity in the illustration at the left is 127 mS, which

translates to 7.9 ohm-m.

The

effect of laminations on resistivity is even more serious because

the logs really measure conductivity, not resistivity. Again

assuming a 50:50 mix of sand and shale laminations, the average

conductivity in the illustration at the left is 127 mS, which

translates to 7.9 ohm-m.  The

case of laminated porosity is slightly different. The resistivity

contrasts are smaller than the laminated shaly sand case. The

resistivity of the higher porosity streaks with low water saturation

may be close to that of the low porosity streak with higher water

saturation. But water zones may look pretty resistive, again giving

misleading water saturation.

The

case of laminated porosity is slightly different. The resistivity

contrasts are smaller than the laminated shaly sand case. The

resistivity of the higher porosity streaks with low water saturation

may be close to that of the low porosity streak with higher water

saturation. But water zones may look pretty resistive, again giving

misleading water saturation.