|

COAL BASICS

COAL BASICS

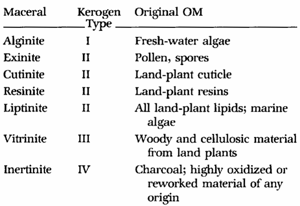

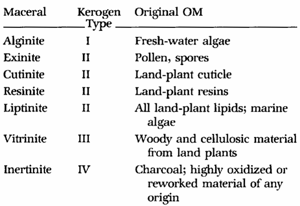

Coal is a term

used to describe a wide range of organic compounds composed of

macerals (as opposed to minerals). A maceral is a component of

coal or oil shale. The term 'maceral' in reference to coal is

analogous to the use of the term 'mineral' in reference to

igneous or metamorphic rocks. Examples of macerals are

inertinite, vitrinite and liptinite. Macerals are forms of

kerogen with varying carbon, oxygen, and hydrogen content. The

kerogen in coals are mostly type 3 and 4 kerpgen.

Coal

macerals are Type 3 and Type 4 Kerogens. Coals are often described

by their common names instead of maceral type. Coal

macerals are Type 3 and Type 4 Kerogens. Coals are often described

by their common names instead of maceral type.

Bituminous coal

is an organic sedimentary rock formed by diagenetic and

submetamorphic compression of peat bog material. Il has been

compressed and heated so that its primary constituents are macerals.

The carbon content of bituminous coal is around 60 to 80%; the rest

is composed of water, air, hydrogen, and sulfur, which have not been

driven off from the macerals. Bituminous coal or black coal is

relatively soft, containing a tarlike substance called bitumen. It

is of higher quality than lignite coal but of poorer quality than

anthracite coal. Bituminous coal

is an organic sedimentary rock formed by diagenetic and

submetamorphic compression of peat bog material. Il has been

compressed and heated so that its primary constituents are macerals.

The carbon content of bituminous coal is around 60 to 80%; the rest

is composed of water, air, hydrogen, and sulfur, which have not been

driven off from the macerals. Bituminous coal or black coal is

relatively soft, containing a tarlike substance called bitumen. It

is of higher quality than lignite coal but of poorer quality than

anthracite coal.

Lignite,

often referred to as brown coal, is a soft brown fuel with

characteristics that put it somewhere between coal and peat. It is

considered the lowest rank of coal, used almost exclusively as a

fuel for steam-electric power generation. Lignite has a carbon

content of around 25 to 35%, a high inherent moisture content

sometimes as high as 66%, and an ash content ranging from 6% to 19%

compared with 6% to 12% for bituminous coal. Lignite,

often referred to as brown coal, is a soft brown fuel with

characteristics that put it somewhere between coal and peat. It is

considered the lowest rank of coal, used almost exclusively as a

fuel for steam-electric power generation. Lignite has a carbon

content of around 25 to 35%, a high inherent moisture content

sometimes as high as 66%, and an ash content ranging from 6% to 19%

compared with 6% to 12% for bituminous coal.

Anthracite is a hard, compact variety of mineral

coal that has a high luster. It has the highest carbon content,

between 92% and 98%, and contains the fewest impurities of all

coals, despite its lower calorific content. Anthracite is the most

metamorphosed type of coal. The term is applied to coals which do

not give off tarry or other hydrocarbon vapours when heated below

their point of ignition. Anthracite is a hard, compact variety of mineral

coal that has a high luster. It has the highest carbon content,

between 92% and 98%, and contains the fewest impurities of all

coals, despite its lower calorific content. Anthracite is the most

metamorphosed type of coal. The term is applied to coals which do

not give off tarry or other hydrocarbon vapours when heated below

their point of ignition.

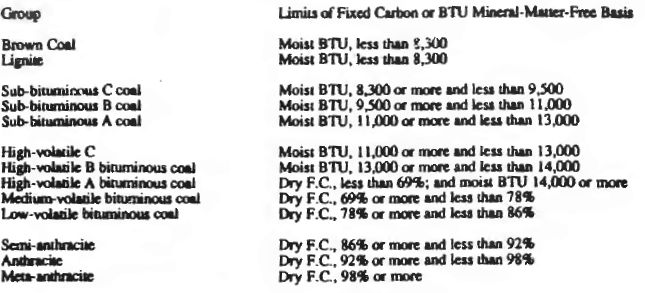

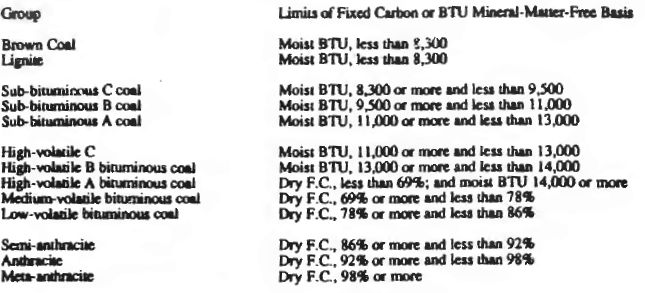

Coal rank depends on thermal maturity

Coal rank is determined by

the BTU heating content or by the fixed carbon content, on a dry,

ash-free basis.

Proximate analysis

Proximate analysis

Proximate analysis of coal is a simple

laboratory method for determining the components of coal, obtained when the coal sample is heated (pyrolysis) under

specified conditions. The coal sample is extracted from a core

and placed quickly in a canister to preserve as much gas as

possible.

As defined by ASTM D 121, proximate

analysis separates the coal into four groups:

1. moisture,

2. volatile matter, consisting of gases and vapors driven off

during pyrolysis,

3. fixed carbon, the nonvolatile fraction of coal

4. ash, the inorganic residue remaining after combustion.

Fixed carbon is also called carbon, dry coal, pure coal, or

dry ash-free coal. The latter term is the most descriptive - dry

ash-free is often abbreviated as "daf" or "DAF".

Moisture

is an important property of coal, as all coals are mined wet.

Groundwater and other extraneous moisture is known as adventitious

moisture and is readily evaporated. Moisture held within the coal

itself is known as inherent moisture and is analyzed quantitatively.

Adventitious moisture is removed in the lab by evaporation in air. Moisture

is an important property of coal, as all coals are mined wet.

Groundwater and other extraneous moisture is known as adventitious

moisture and is readily evaporated. Moisture held within the coal

itself is known as inherent moisture and is analyzed quantitatively.

Adventitious moisture is removed in the lab by evaporation in air.

Moisture may occur in four possible forms within coal:

1. surface moisture: water held on

the surface of coal particles or macerals

2. hydroscopic moisture:

water held by capillary action within the micro-fractures of the coal

3. decomposition moisture: water held within the coal's decomposed

organic compounds

4. mineral moisture: water which comprises part of

the crystal structure of hydrous silicates such as clays

Total

moisture is analyzed by loss of mass between an air-dried sample and

the sample after driving off the inherent moisture with heat. This is achieved by any of the following

methods;

1. heating the coal with toluene

2. drying in a minimum free-space oven at 150 °C (302 °F) within a

nitrogen atmosphere

3. drying in air at 100 to 105 °C (212 to 221 °F)

Methods 1 and 2 are suitable with low-rank coals but method 3 is

only suitable for high-rank coals as free air drying low-rank coals

may promote oxidation.

Volatile matter

in coal refers to the components of coal, except for moisture, which

are liberated at high temperature in the absence of air. This is

usually a mixture of short and long chain hydrocarbons, aromatic

hydrocarbons, and some sulfur. In Australian and British

laboratories, this involves heating the coal sample to 900 ±

5 °C (1650 ±10 °F) for 7 minutes in a cylindrical silica crucible in

a muffle furnace. American procedures involve heating to

950 ± 25 °C (1740 ± 45 °F) in a vertical platinum crucible. These

two methods give different results and thus the method used must be

stated. Volatile matter

in coal refers to the components of coal, except for moisture, which

are liberated at high temperature in the absence of air. This is

usually a mixture of short and long chain hydrocarbons, aromatic

hydrocarbons, and some sulfur. In Australian and British

laboratories, this involves heating the coal sample to 900 ±

5 °C (1650 ±10 °F) for 7 minutes in a cylindrical silica crucible in

a muffle furnace. American procedures involve heating to

950 ± 25 °C (1740 ± 45 °F) in a vertical platinum crucible. These

two methods give different results and thus the method used must be

stated.

Fixed carbon

content of the coal is the carbon found in the material which is

left after volatile materials are driven off. This differs from the

ultimate carbon content of the coal because some carbon is lost in

hydrocarbons with the volatiles. Fixed carbon is used as an estimate

of the coke yield from a sample of coal.

Fixed carbon is determined by subtracting the mass of volatiles,

determined above, from the original mass of

the coal sample. Fixed carbon

content of the coal is the carbon found in the material which is

left after volatile materials are driven off. This differs from the

ultimate carbon content of the coal because some carbon is lost in

hydrocarbons with the volatiles. Fixed carbon is used as an estimate

of the coke yield from a sample of coal.

Fixed carbon is determined by subtracting the mass of volatiles,

determined above, from the original mass of

the coal sample.

Ash

content of coal is the non-combustible residue left after coal is

burnt. It represents the bulk mineral matter after carbon, oxygen,

sulfur and water (including from clays) has been driven off during

combustion. Analysis is fairly straightforward, with the coal

thoroughly burnt and the ash material expressed as a percentage of

the original weight. Ash

content of coal is the non-combustible residue left after coal is

burnt. It represents the bulk mineral matter after carbon, oxygen,

sulfur and water (including from clays) has been driven off during

combustion. Analysis is fairly straightforward, with the coal

thoroughly burnt and the ash material expressed as a percentage of

the original weight.

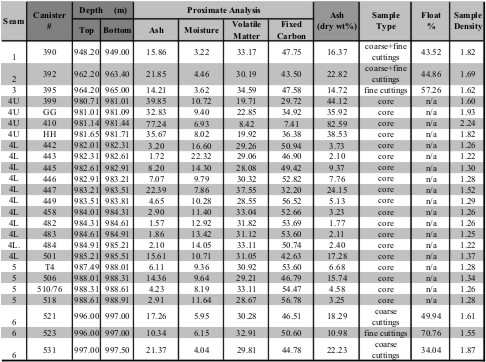

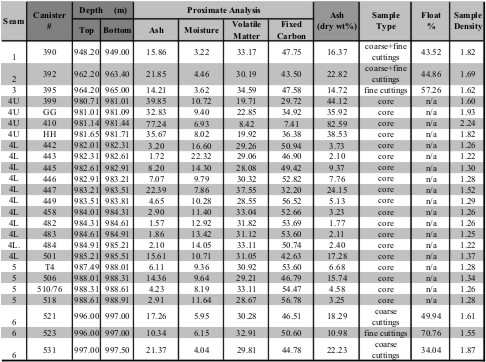

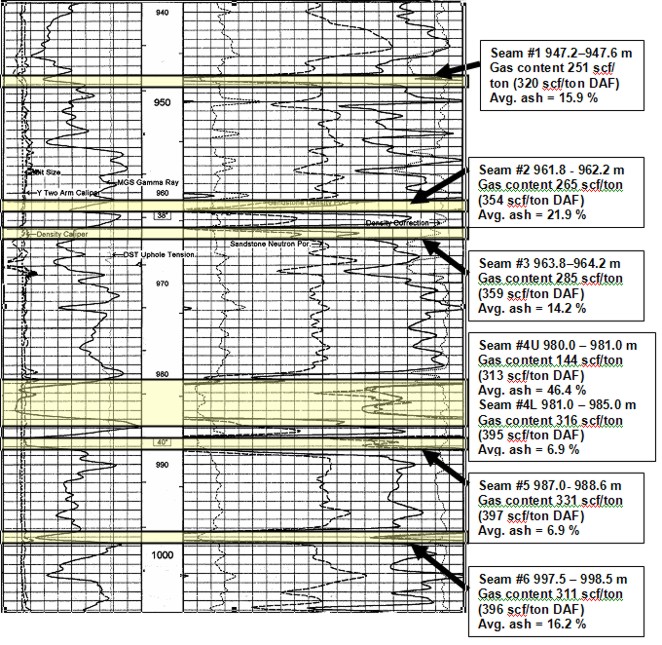

Example of Proximate Analysis of

several coal seams - data is in Weight %

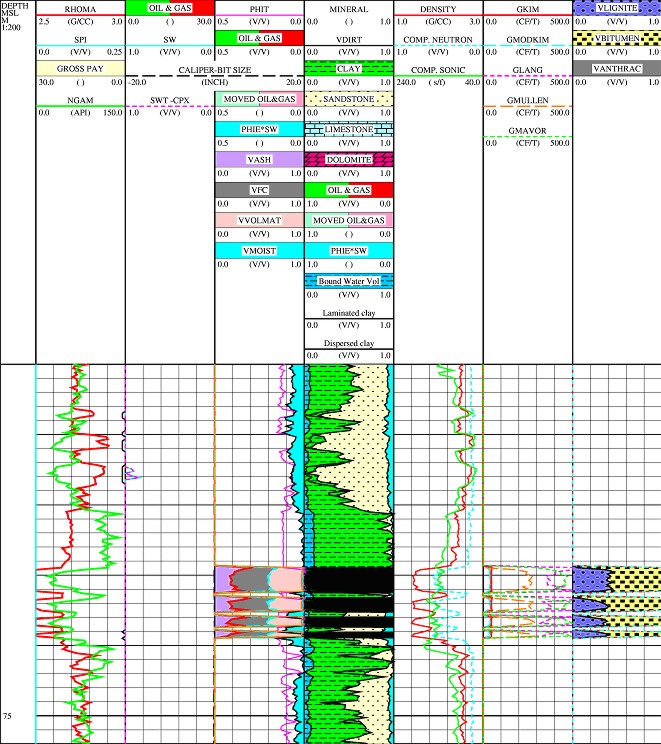

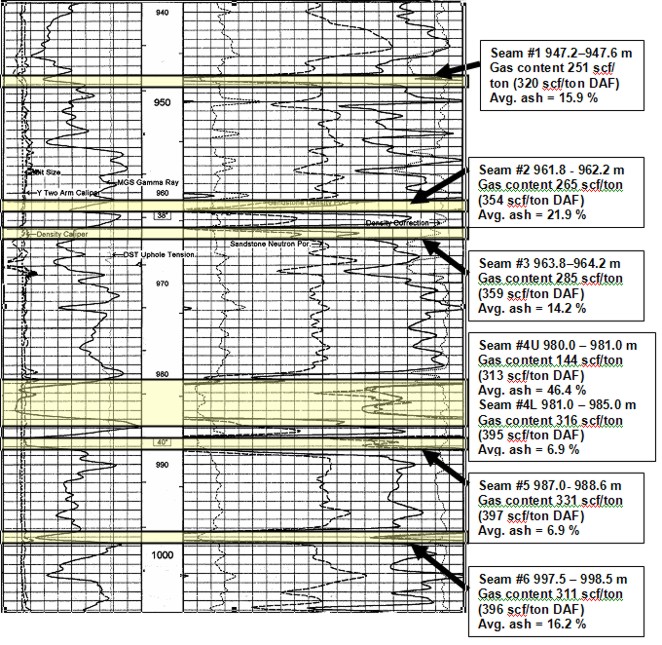

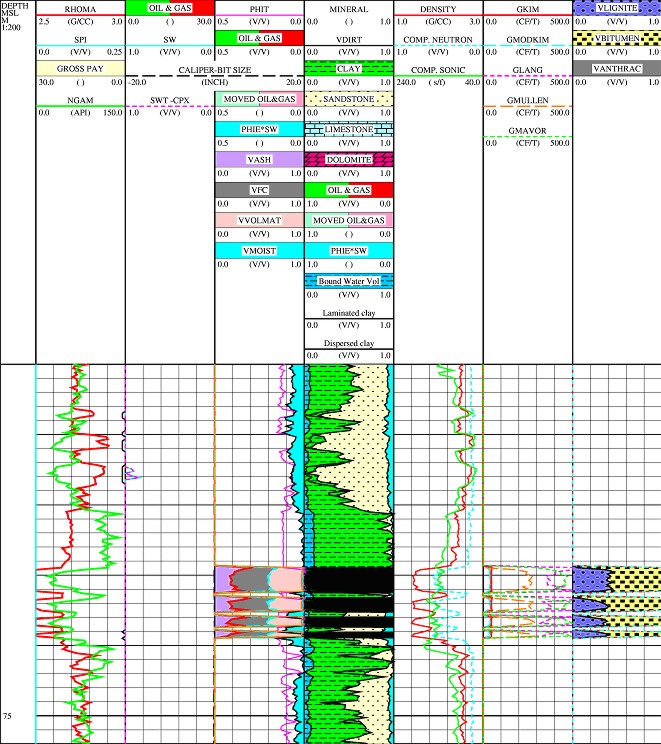

Well log showing location of coal

layers analyzed by proximate analysis. Log curves are GR, CAL, PE,

neutron, density, density correction.

Float

Sink Analysis is used to separate non-coal cavings

from cuttings samples. The crushed material is placed in a liquid

with a density of 1.75 g/cc. The coal fraction is floated off and

the non-coal sinks and is removed. Some mineral (ash) in the coal

may sink, reducing the apparent ash content.

By

comparing the ash analysis to the float sink analysis with that from

core analysis, the gas contents can be normalised to reflect true

ash contents of the coal cuttings.

Float

Sink Analysis is used to separate non-coal cavings

from cuttings samples. The crushed material is placed in a liquid

with a density of 1.75 g/cc. The coal fraction is floated off and

the non-coal sinks and is removed. Some mineral (ash) in the coal

may sink, reducing the apparent ash content.

By

comparing the ash analysis to the float sink analysis with that from

core analysis, the gas contents can be normalised to reflect true

ash contents of the coal cuttings.

Vitrinite is the most common component of coal.

It is also abundant in kerogen, derived from the same

biogenic precursors as coals, namely land plants and humic peats.

Vitrinite forms diagenetically by the thermal alteration of lignin

and cellulose in plant cell walls. It is therefore common in

sedimentary rocks that are rich in organic matter, such as shales

and marls with a terrigenous origin.

Conversely, carbonates, evaporites, and well-sorted sandstones have

very low vitrinite content. Vitrinite is absent in pre-Silurian

rocks because land plants had not yet evolved. Vitrinite is the most common component of coal.

It is also abundant in kerogen, derived from the same

biogenic precursors as coals, namely land plants and humic peats.

Vitrinite forms diagenetically by the thermal alteration of lignin

and cellulose in plant cell walls. It is therefore common in

sedimentary rocks that are rich in organic matter, such as shales

and marls with a terrigenous origin.

Conversely, carbonates, evaporites, and well-sorted sandstones have

very low vitrinite content. Vitrinite is absent in pre-Silurian

rocks because land plants had not yet evolved.

Vitrinite reflectance

was first studied by coal geologists attempting to determine the

thermal maturity, or rank, of coal beds. More recently, it is used

to study sedimentary organic matter from kerogen. It is sensitive

to temperature ranges that correspond to hydrocarbon generation (60

to 120°C). This means that, with a suitable calibration, vitrinite

reflectance can be used as an indicator of maturity in hydrocarbon

source rocks. Generally, the onset of oil generation is correlated

with a reflectance of 0.5 to 0.6% and the termination of oil

generation with reflectance of 0.85 to 1.1%

Vitrinite reflectance

was first studied by coal geologists attempting to determine the

thermal maturity, or rank, of coal beds. More recently, it is used

to study sedimentary organic matter from kerogen. It is sensitive

to temperature ranges that correspond to hydrocarbon generation (60

to 120°C). This means that, with a suitable calibration, vitrinite

reflectance can be used as an indicator of maturity in hydrocarbon

source rocks. Generally, the onset of oil generation is correlated

with a reflectance of 0.5 to 0.6% and the termination of oil

generation with reflectance of 0.85 to 1.1%

VISUAL LOG ANALYSIS OF COAL Beds

VISUAL LOG ANALYSIS OF COAL Beds

The use of well logs for analyzing coal deposits dates back many

years. Most methods are based on a multi-mineral model which

solves for moisture, volatile components, fixed carbon, and ash.

These are the same components determined from coal cores or

sample chips by

proximate analysis.

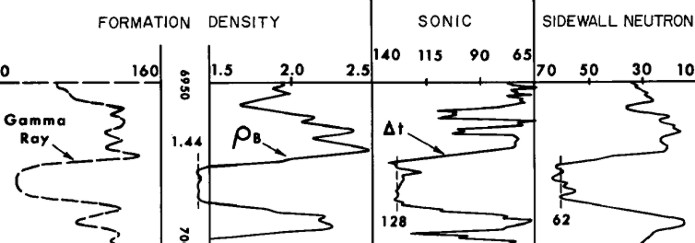

Visual analysis of logs for coal is relatively unambiguous.

High neutron porosity, high density porosity (low density), high

sonic, high resistivity, and clean gamma ray mean coal.

Thresholds on each curve are used to trigger a coal flag. Three

or more flags is a pretty good indication of the presence of

coal. Some coals are very dirty (shaly) so the gamma ray and

resistivity may not trigger.

COAL ANALYSIS frOm LogS

COAL ANALYSIS frOm LogS

The use of well logs for analyzing coal deposits dates back many

years. Most methods are based on a multi-mineral model which

solves for moisture, volatile components, fixed carbon, and ash.

These are the same components determined from coal cores or

sample chips by proximate analysis.

One log

analysis model calculates a 3-mineral model from PE, density,

neutron, sonic crossplot methods and solves for the fraction of

lignite, bituminous coal, and anthracite. With this

breakdown, the coal matrix density can be determined, and the other

parameters follow from this value:

1: DENSMAcoal = Vlignite * 1.19 + Vbituminous * 1.34 +

Vanthracite * 1.47

An alternative method is a 3-mineral model using ash, fixed

carbon, and moisture. The GR is used to obtain Vclay, making a

4-mineral model relatively easy. Both models can be solved by

crossplots or the math shown elsewhere in this Handbook.

LOG

PARAMETERS FOR COAL TYPE ANALYSIS

DENSMA PHIN

DTC DTCMA PE Carbon

Oxygen Hydrogen

g/cc frac

us/ft us/m us/ft us/m

Wt% Wt% Wt%

Anthracite 1.47 0.41

105 345 48 157 0.16 95

1 2

Bituminous 1.24 0.60+ 120

394 44 144 0.17 82 10

5

Lignite 1.19

0.54 160 525 50 164 0.20

71 22 6

Peat 1.14

0.26 0.25

57 36 6

MATRIX PARAMETERS FOR 3-MINERAL MODEL - COAL COMPOSITION

DENSMA PHIN DTCMA PE

g/cc frac us/ft us/m

cu

Ash (Quartz) 2.65 0.00 55 182 1.8 Could vary if

other minerals (eg calcite) are also present

Ash (Clay) 2.18 - 2.65 0.25 80 250 3.5 Includes clay

bound water, varies with clay mineral

Carbon 1.19 - 1.47 0.60 120 394 0.2 Varies with

coal type (dry, ash-free value)

Water 1.00 1.00 200 656 0.1 Free water

or "moisture", excludes clay bound water

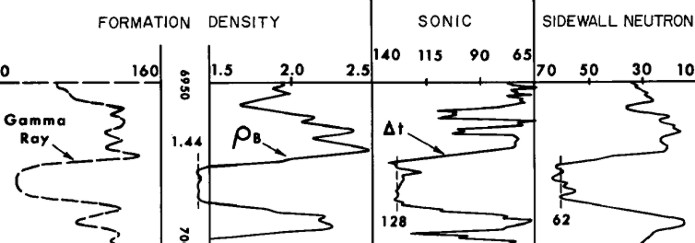

Density neutron crossplot for coal analysis (bottom left),

density sonic crossplot (top right). Data points show that the ash

in this coal is mostly clay (log data falls to the right of the

quartz point).

The mineral end points are not firm, so some experimentation

and sample descriptions are needed. If a 3-mineral model is not

possible, the analyst must decide on the correct coal type.

A dry clay model can also be used, but the water term will include

the clay bound water, not just the free water. It can be removed by

subtracting clay bound water from the tptal to get the free water

answer.

The ash data

points may vary with clay type and other noncombustible mineral

content, so crossplots of lab ash content (by volume) versus log

readings can help pin down these values.

CALCULATING COAL PROPERTIES

CALCULATING COAL PROPERTIES

The following equations are found in the

coal assay literature and are based on correlations between core

analysis values and log data. Parameters can be tuned by making

your own crossplots. Standard 3- and 4- mineral models using

simultaneous equations, DENSma-Uma crossplots, or Mlith-Nlith

crossplots (or equivalent math) are probably more practical when

the core data correlations are not available.

Initial results are in volume fractions

and are converted to weight fractions by using the density of

each component.

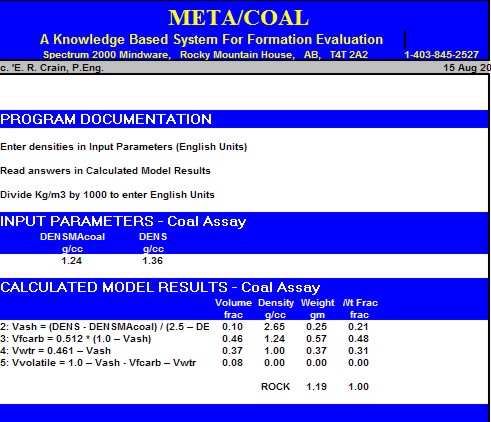

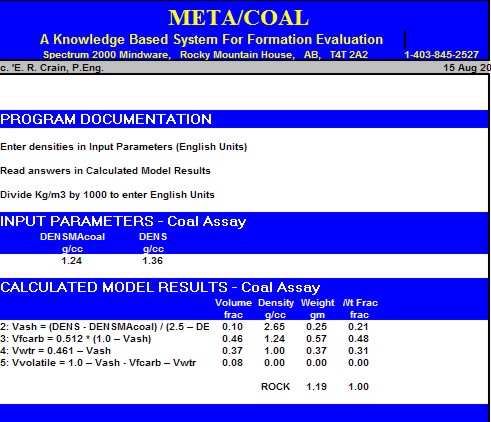

Ash Content: Ash Content:

2: Vash = (DENS - DENSMAcoal) / (2.5 –

DENSMAcoal)

OR 2a: Vash = 0.65 * (DENS - 1.00)

Equations specific to a project area can be obtained by

plotting coal assay data versus density log data, as shown in the

examples at the right.

Fixed Carbon (dry coal):

3: Vfcarb = 0.512 * (1.0 – Vash)

Moisture (free water):

4: Vwtr =

0.461 – Vash

Volatile Matter:

5: Vvolatile = 1.0 – Vash - Vfcarb – Vwtr

All proximate analysis results are

reported in weight fraction or percent. To convert log analysis

volume fractions to weight fractions, use the following:

6: WTash = Vash * DENSash

7: WTfcarb = Vfcarb * DENSfcarb

8: WTwtr = Vwtr * DENSwtr

9 : WTvolatile = Vvolatile * DENSvolatile

10: WTcoal = WTash + WTfcarb + WTwtr + WTvolatile

Mass fractions are as follows

(multiply by 100 to get weight percent):

11:

Wash = WTash / WTcoal

12: Wfcarb = WTfcarb / WTcoal

13: Wwtr = WTwtr / WTcoal

14: Wvolatile = WTvolatile / WTcoal

Weight percent is often used in reports:

15: WT%ash = 100 * Wash

16: WT%fcarb = 100 * WTfcarb

17: WT%wtr = 100 * WTwtr

18: WT%volatile = 100 * WTvolatile

Where:

DENS = density log reading in a coal (g/cc)

DENSMAcoal = matrix density of a coal (g/cc)

DENSxxx = density of a component (g/cc)

Vxxx = volume fraction of a component (fractional)

WTxxx = weight of a component (grams)

Wxxx = mass fraction of a component (fractional)

WT%xxx = weight percent of a component (percent)

META/LOG

"COAL"

SPREADSHEET -- Coal ASSAY FROM LOG OR CORE ANALYSIS META/LOG

"COAL"

SPREADSHEET -- Coal ASSAY FROM LOG OR CORE ANALYSIS

This

spreadsheet calculates a Coal Assay that can be used to evaluate

coal quality and provides a comparison between core and log analysis

data. It is the same asssay method used to get started with a coal

bed methane analysis.

SPR-14 META/LOG COAL BED METHANE (CBM) CALCULATOR

Calculate coal assay, coal bed methane, adsorbed gas In

place

Sample output from "META/COAL" spreadsheet for coal

qusality analysis.

Coal LOG analysis EXAMPLE Coal LOG analysis EXAMPLE

Log analysis of

an Alberta Foothills coal using a model for coal composition (fixed

carbon, volatiles, moisture, and ash (2nd track from the

right). These results can be ca;ibrated to the proximate analysis

from lab measurements.

Example of coal

log analysis results using a 3-mineral model for coal type (lignite,

bituminous, anthracite) in right hand track. Zones outside the coal

are analyzed with conventional oil and gas models.

|

Ash Content:

Ash Content: