|

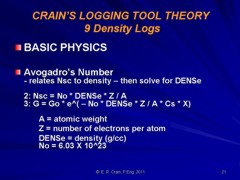

DENSITY LOG BASICS

DENSITY LOG BASICS

This page describes density logs

profiles, in the order of their appearance over the years.

This presentation style provides insights into tool

evolution, and a specific tool’s capabilities and

limitations. You will find most these tool types in your

well files – here’s your chance to learn more about them.

Density logs first appeared in 1957, based on the principle of gamma

ray absorption by Compton scattering.

Early tools were called gamma - gamma density logs because they

emitted and recorded gamma rays. The log displayed counts per

second, which was transformed to density by a semi-logarithmic

transform. Modern tools have two detectors, which allows borehole

compensation to be applied.

They are scaled in units of density

(grams / cc or Kilograms / cubic meter). Some density logs also

record photoelectric capture cross section which is useful in

lithology analysis. Some density logs are displayed in porosity

units (percent or decimal fraction).

The gamma ray source foe all tools is cesium 137.

For more detail on the physics of the density log

measurement, see

Density Theory.

The

tool can be used in air or mud filled open boreholes. A cased

hole tool is available in some areas.

References:

1. Logging Empty Holes

C.G. Rodermund, R.P. Alger, J. Tittman,

Oil and Gas Journal, 1961

2. Formation Density Log Application in Liquid-Filled Holes

R.P. Alger, L.L. Raymer, W.R. Hoyle , M.P. Tixier, JPT, 1964

3. Litho-Density Log Interpretation

J.S. Gardner, J.L. Dumanoir,

SPWLA, 1980

UNCOMPENSATED DENSITY LOG

UNCOMPENSATED DENSITY LOG

Early density

logs run by the major service companies had only one detector and were recorded in counts per

second. There were no automatic borehole corrections as there is

today and calibration to density or porosity took some effort.

Such logs are still in widespread use in mineral

exploration and resource assessment. The USGS, NRC, and a number of

independent service companies run slim hole density logs of this design.

I ran a set on Melville Island in the Canadian Arctic in 1969

for sulphur exploration. Aside from trying to stay warm and keep

the liquid ink recorder from freezing up, everything ran

smoothly

for 4 months before returning to gentler climates.

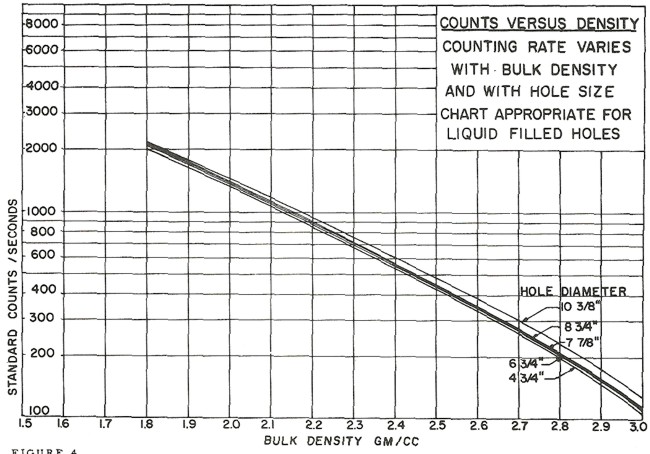

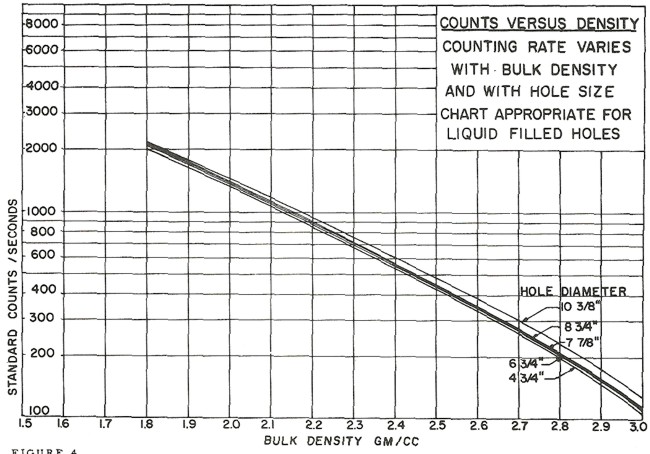

Density is derived with a semi-logarithmic transform. If no

appropriate tool specific chart is available the High Low

porosity technique as described for the neutron log is used.

Here, high count rate = low density = high porosity. Semi-log crossplots of

count rate versus core density or core porosity will calibrate the

method. These tools have a single detector and are not compensated

for borehole effects. Slim hole versions were widely used in strat

holes and in mineral exploration projects. Charts for some specific

tools can be found in the literature, such as the one shown below.

The uncompensated density log produces a single log curve scaled

in counts per second. Some independent logging contractors can

provide a log scaled in porosity or density units. Some

tools were run with a gamma ray log.

Counts per second to density transform for a Schlumberger PGT-A

density tool. Each tool iteration and each service company requires

a specific chart. Density varies with hole size, mud weight, and mud

cake thickness.

Single detector

density tools are severely affected by hole size, mud weight, mud cake

thickness, source type and strength, source detector spacing, and

detector efficiency. The High-Low calibration method compensates for

all these problems, but available charts do not. In the earliest

versions of these tools, the source strength decayed rapidly, so

count rates definitely need to be normalized on a well by well

basis.

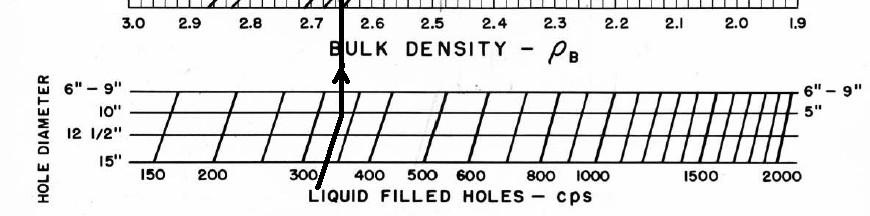

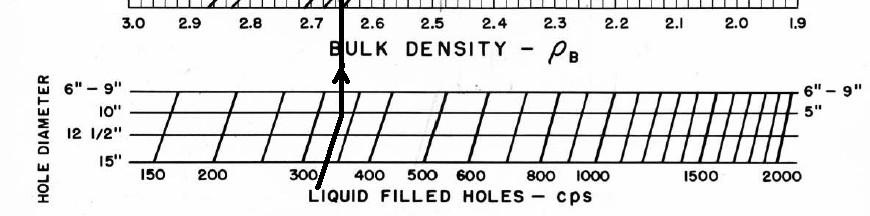

Most density transforms never made it into

published chart books. This one did -

Schlumberger PGT-C or D density count rates to porosity. Additional

charts are available to correct for mud cake thickness and mud

weight, and for air-filled holes. The count rate charts appeared in

1966 chart books, well after they were no longer needed, and

disappeared after 1968. Most density count rate charts are very hard

to find unless you have a good supply of ancient chart books from

1958 through 1968 - a 10 CD set of ancient chart books was

COMPENSATED DENSITY LOG (FDC)

COMPENSATED DENSITY LOG (FDC)

The

borehole compensated formation density logging tool emits gamma rays from a chemical source at the

bottom of the tool The gamma rays enter the surrounding

rocks where some are absorbed. Some gamma rays survive to reach

scintillation counters mounted about 18 and 24 inches above the

source. The number of gamma rays arriving at the far detector is

inversely proportional to the electron density of the rock, which in

turn is proportional to the actual rock density. Data from the

closer detector is used to correct for borehole effects.

Porosity

can be derived from density and can be presented as a percent or as

a decimal fraction on the log. This porosity may still contain

artifacts from shale and minerals not accounted for by the logging

computer, so this porosity is NOT a final answer.

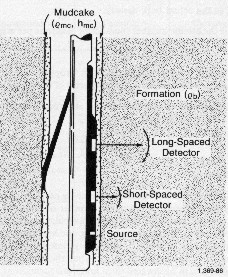

A typical density logging tool is shown

at the right.

The tool is pressed against one side of the borehole by

a back-up arm that also serves to measure a diameter of the

borehole. Two detectors at fixed spacings from the source are

shown. The source is well-shielded from the two detectors and

only scattered gamma radiation is detected. The intensity of

the scattered radiation will be dominated by the density variations

along the path from source to detector. A typical density logging tool is shown

at the right.

The tool is pressed against one side of the borehole by

a back-up arm that also serves to measure a diameter of the

borehole. Two detectors at fixed spacings from the source are

shown. The source is well-shielded from the two detectors and

only scattered gamma radiation is detected. The intensity of

the scattered radiation will be dominated by the density variations

along the path from source to detector.

If there is no stand-off (of mud or mudcake) between the tool face and the formation, and if the

tool is properly calibrated, then the apparent density from

both detectors will be the same and equal to the true formation density.

If they are different, there must be mud between the tool face

and the rock.

If there is some standoff, a correction

to the density from the long spaced detector can be generated

from the difference between the apparent density seen by the

far and the near detectors. The actual correction function

can be determined empirically by placing the density device

in a number of formations to measure the apparent long-spaced

and short-spaced densities for various thicknesses of mudcake

of a variety of densities. Computer modeling has augmented

these laboratory studies.

In addition

to the density and optional porosity curves, a caliper and gamma

ray curve are also presented, along with the density correction

curve. Note that the correction has already been applied to the

recorded density data by the computer in the logging truck.

LITHO-DENSITY LOG (LDT) LITHO-DENSITY LOG (LDT)

The litho density logging tool and

the log display look very similar to the older version, except

for the addition of one new log curve, the photo electric effect

(PE or PEF).

The energy of the returning gamma rays is a function of the PEF

of the rock, which is indicative of mineralogy. To measure PEF,

the detectors were changed to measure both gamma ray count rates

for the density measurement and also the gamma ray energy levels

for the PEF measurement.

Most modern two-detector density devices

use multiple energy windows to derive the density, the photoelectric

factor, and the correction curve. In one

three-detector wireline version, the combination of multiple

detectors and multiple energy windows produce on the order

of a dozen counting rate measurements at each depth. Each counting rate can be described

by a forward model relating the rate to the five important

parameters of density logging: formation density, formation

photoelectric factor, mudcake density, mudcake photoelectric

factor, and the thickness of the mudcake.

For more detail on the physics of the

PEF measurement, see

Density Theory.

The log curves presented are the same as the older FDC log, with

the PEF added.

ADVERSE BOREHOLE CONDITIONS

ADVERSE BOREHOLE CONDITIONS

Standoff caused by rough or large borehole leads to useless

density data if the problem is severe enough. The density correction

curve, the caliper curve, and the density curve itself help to flag

these intervals. Because the backup arm exerts considerable

pressure, mudcake thickness is not usually an issue, but that same

pressure forces the measuring skid into the large diameter of an

oval borehole. This occurs in stressed regions. The large diameter

has the worst borehole condition so we get the worst possible

density log.

In the mid 1970's a 90 degree offset tool was developed to

reduce the chance of logging the large diameter of the borehole. It

consisted of a second backup arm at 90 degrees to the original,

pressured a little higher, that forced the tool skid into the

smaller diameter. This led to the concept of the dual axis, or X and

Y axis calipers. Later development led to a dual density tool,

essentially two complete density logs on the same tool string,

positioned at 90 degrees from each other, resulting in reasonable

complete log coverage in stressed boreholes.

CAUTION: Do not use density data when you suspect standoff

problems. A reasonable guide would be a density correction more than

0.15 gm/cc (150 kg/m3) is highly suspect and greater than 0.20 gm/cc

is useless. If density porosity is greater than neutron porosity,

and no gas is expected in the rock, the density is probably useless

(provided the logs were run on a porosity scale appropriate for the

mineralogy). Noisy, hashy, or impossibly high density porosity

probably indicates a bad log, even when the caliper and correction

curve show no problems. The density skid is about 2 feet long so

there can be significant breakouts within that distance that the

caliper cannot see.

DUAL DENSITY LOG AND 90 DEGREE OFFSET TOOL

DUAL DENSITY LOG AND 90 DEGREE OFFSET TOOL

Some areas are heavily stressed and stress release

during drilling causes oval boreholes or large breakouts in the

maximum stress axis of the borehole. The skid and backup arm of the

density log often end up in this axis so we end up logging the bad

side of the borehole. Another strong-arm caliper set at 90 degrees

to the density caliper forces the density skid into the

good side of the borehole, resulting in better log quality.

Some operators ran several logging passes in an effort to get the 90

degree offset tool to log most of the interval on the good side of

the hole.

The 90 degree technique is still used but doesn't always succeed.

An alternative was called the dual density

log. There were literally two density tools coupled together, one

above the other at 90 degrees so that while one tool was facing the

bad side of the borehole, the other was facing the good side. Thus

two independent density logs were run simultaneously.

During data processing, the computer code was adapted to take the

maximum of the two density corves, eliminating most of the bad data.

Cable torque forces the tool set to rotate in a stepwise fashion as

it travels up the borehole. There may be minor bad hole effects at

these spots. I am not sure such a combo could be run today.

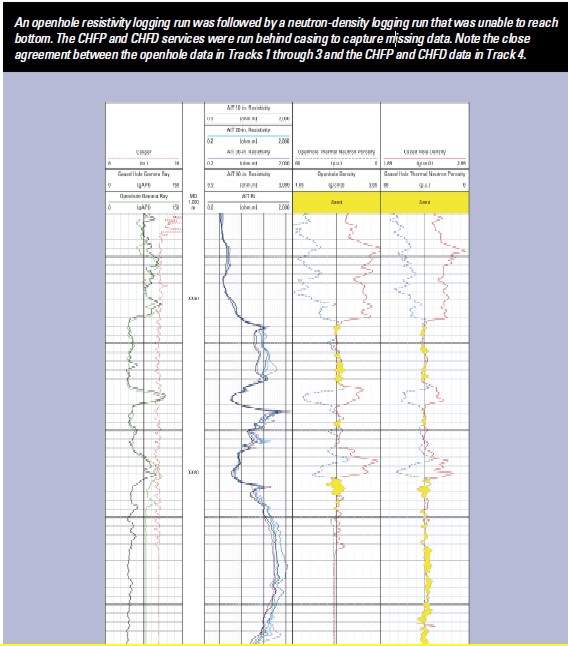

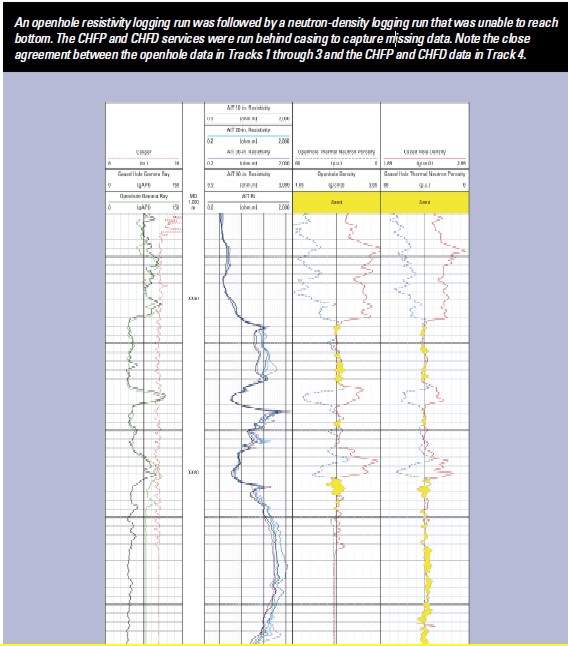

Cased Hole Formation Density (CHFD)

Cased Hole Formation Density (CHFD)

Cased hole formation density logs make accurate formation density

measurements in cased wells. A chemical gamma ray source and

three-detector measurement system are used to make measurements in a

wide range of casing and borehole sizes. The density measurement

made by the three detector system is corrected for casing and cement

thickness.

The

density data are used to calculate porosity and determine the

lithology. The combination of density and neutron data is used to

indicate the presence of gas.

Applications

■ Porosity determination

■ Lithology analysis and identification of minerals

■ Gas detection

■ Hydrocarbon density determination

■ Shaly sand interpretation

■ Rock mechanical properties calculations

■ Determination of overburden pressure

■ Synthetic seismogram for correlation with seismic

DENSITY POROSITY LOGS

DENSITY POROSITY LOGS

Density is proportional to porosity, shale content,

and matrix rock type, just as for the sonic log. Both are also

affected by the fluid in the formation and both must be run

in a liquid filled borehole, although the liquid does not have

to conduct electricity.

Compensated density log presentation

showing density (solid line), density porosity on a

limestone

scale (dashed line), and density correction, plus gamma ray

and caliper in Track 1.

The density log can be presented in units of density,

that is, grams per cc or Kilograms per cubic meter. Some log

presentations portray the density data as its equivalent porosity,

translated with a particular lithology assumption. Some show

both density and density porosity, as in the image above.

The scales are usually called Sandstone or Limestone

scales to reflect the assumption that was made to create them.

Dolomite scales also exist on a few logs. The relationships

are:

1: PHID = (DENS - KD6) / (KD7 - KD6)

2: DENS = PHID * KD7 + (1 - PHID) * KD6

Where:

KD6 = 2.65 for Sandstone scale (English)

KD6 = 2.71 for Limestone scale (English)

KD6 = 2.87 for Dolomite scale (English)

KD6 = 2650 for Sandstone scale (Metric)

KD6 = 2710 for Limestone scale (Metric)

KD6 = 2870 for Dolomite scale (Metric)

KD7 = 1.00 for English units

KD7 = 1000 for Metric units

Because some logs do not have a density scale, you

may have to translate the recorded log into density units so

that it can be used, for example to calculate acoustic impedance

for a seismic application.

To use data from a density log, you must correctly

identify both the scale type, lithology assumption, and the

two end point values. Other log curves are often present, such

as the density correction, compensated neutron, gamma ray,

caliper, bit size, cable tension, and photoelectric effect. You have to choose the correct curve from

among those presented. Editing for bad hole and casing effects

will be mandatory if the log is to be used to generate a synthetic

seismogram. The density data should not be used for any purpose

if the density correct is larger than 0.200 gm/cc (200 kg/m3).

CAUTION: The use of an inappropriate porosity scale on a

combination density - neutron log presentation can be EXTREMELY

misleading. For example, sandstone rock recorded on a limestone

scale will cause the density porosity to be higher than the neutron

porosity by as much as 6 to 8% (0.06 to 0.08 decimal fraction). This

is often interpreted to indicate the presence of gas, leading to

very expensive completion mistakes. The density - neutron crossover

needs to be considerably greater than 8% to indicate gas in this

situation. Similarly, a log run on dolomite scale through a

limestone rock will show up to 12% porosity crossover, just because

of the inappropriate scale, not because of gas. Use the PE curve to

determine lithology, then interpret the crossover correctly. PE near

2 = sandstone, PE near 3 = dolomite, PE near 5 = limestone.

DENSITY INTERFACE LOG and SONAR LOGS

DENSITY INTERFACE LOG and SONAR LOGS

Storage caverns are created on

purpose in salt beds to store gas or oil near points of demand to

help meet peak loads. They must be tested before use and monitored

during use with specialized logging tools.

Density interface logs are used to look for fluid

interfaces in existing oil or gas storage caverns. Sonar logs are

used to find the distance to the cavern wall in a 360 degee survey

that helps determine the cavern volume. Pressure tests are used to

check cavern an wellbore integrity. 3-D seismic surveys are run

prior to cavern construction to locate faults and fractures aboce

and below a proposed cavern site. 3-D seismic may also be used in

exicting salt solution mines before conversion to hydrocarbon

storage.

You don't need a very sophisticated

or well calibrated density logging tool to do this work. A single detector tool recording

its response in counts per second (cps) will do the job. They can be

run on slick line with a memory device or on wireline in real time.

The logs may be non-standard in presentation and may not be recorded

in digital files in LAS format.

During the initial mechanical interface test

(MIT) of a gas storage cavern, the survey is run in time-lapse mode.

With some water in the cavern, nitrogen is injected under pressure

and held for at least 24 hours. If the water level changes or

pressure drops more than 10 psi,

the test has failed. Remedial action, if possible, must be

undertaken before the cavern can be used to store gas. During

operation of the cavern, the objective is to observe the water--gas

contact depth in the cavern, along with the reservoir pressure, to

monitor remaining gas volume.

The original cavern volume is determined by a

sonar log. This device maps the travel time of sound from the tool

to the cavern wall and back again. By pinging the sonar in varying

directions, a map of the distance to the walls can be made at

various depths in the cavern. The survey ends up as a 3-D image of

the cavern, which is used for routine gas volume modeling.

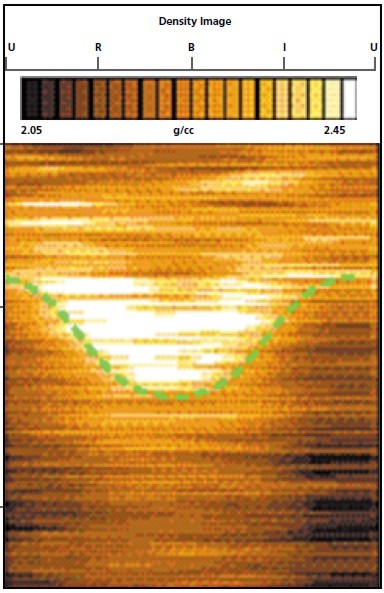

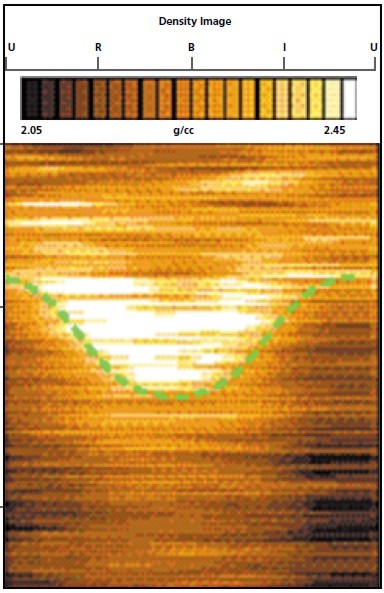

LWD DENSITY IMAGE LOG

LWD DENSITY IMAGE LOG

Logging while drilling (LWD) offers many alternatives that can be

displayed as an image log. The example at right is a density image

log. Low density values are shaded dark and can be interpreted as

porosity or shale. A gamma ray log run with the drill string helps

distinguish between these alternatives. White colours represent low

porosity or tight rocks.

The LWD density tool is a focused source and detector set, similar

in concept to an open hole density logging tool. As it

rotates, it scans the borehole wall to form the image. Data is

stored in memory downhole, while only the composite density curve is

sent uphole, where it is displayed in standard well log format

along with any other LWD curves available in the tool string.

DENSITY LOG CURVE NAMES DENSITY LOG CURVE NAMES

Formation Density Log Uncompensated Type (DL)

Formation Density Log Uncompensated Type (DL)

| Curves |

Units |

Abbreviations |

| density

count rate |

cps |

DCPS |

| *

gamma ray |

API |

GR |

| *

caliper |

in

or mm |

CAL |

Formation Density Log Compensated Type (FDC)

Formation Density Log Compensated Type (FDC)

| Curves |

Units |

Abbreviations |

|

density |

gm/cc

or kg/m3 |

RHOB or DENS |

|

gamma ray |

API |

GR |

| *

porosity from density |

%

or frac |

DPHI

or PHID |

| *

formation factor from density |

frac |

FD |

| caliper |

in

or mm |

CAL |

| *

density correction |

gm/cc

or kg/m3 |

DRHO |

This log was often presented on the same log

display as the compensated neutron log, and more rarely

in the right hand track on a dual induction log.

Litho-Density Log (LDT)

Litho-Density Log (LDT)

| Curves |

Units |

Abbreviations |

|

density |

gm/cc

or kg/m3 |

RHOB or DENS |

|

gamma ray |

API |

GR |

| *

porosity from density |

%

or frac |

DPHI

or PHID |

| *

formation factor from density |

frac |

FD |

| caliper |

in

or mm |

CAL |

| *

density correction |

gm/cc

or kg/m3 |

DRHO |

| photo

electric cross section |

cu |

PE |

This log was often presented on

the same log display as the compensated neutron log,

EXAMPLES OF DENSITY LOGS

EXAMPLES OF DENSITY LOGS

Density logs presented with other log curves - neutron - density

(top right) and induction -

density (bottom left).

Typical display format for

PE-density porosity-neutron porosity log on a sandstone scale. The

density correction curve may appear on the left or right side of the

wide track. A density scale of 1.65 to 2.65 gm/cc may be used

instead of the density porosity scale.

|