|

ANCIENT LOG BASICS

ANCIENT LOG BASICS

Ancient logs are a great mystery to most people because they are

not seen often and are usually discarded as useless. This latter

opinion is far from the truth. Modern computer software for petrophysical

analysis can glean considerable amounts of reservoir property

data from these old logs, especially when the work is calibrated

with core data and modern logs in nearby offset wells.

The

term "ancient logs" is usually applied to the electrical

survey (ES), microlog (MLC), and gamma ray neutron (GRN) that became available in the early 1930's and were in common use

well into the late 1950's. At this time, induction (IES) and sonic

(SL) logs gradually supplanted the ES and GRN. Early forms of

the laterolog (LL7 and LL3) and microlaterologs (MLLC) were also

developed to replace the ES and MLC in salt mud environments.

In the early 1960's, induction, sonic, and density log

presentations were fairly primitive by today's standards, and

some people consider them to be ancient logs also. A brief

description of all logging tools, including ancient logs, can be

found in the Tool Theory section of this Handbook.

By

the mid 1960's, compensated neutron and density logs (scaled in

porosity units), as well as borehole compensated sonic logs, were

beginning to augment porosity determination. By the mid 1970's,

"ancient" logging tools disappeared from most parts of

the World,

but ancient tools are still run in China, the former Soviet Union

republics,

and other areas that could not afford newer technology.

To

put this in perspective, here is a brief history timeline.

DEVELOPMENTS

IN WELL LOGGING

|

| |

1869

First temperature log Lord Kelvin

1883 Single electrode resistivity log patented by Fred

Brown

1912 First surface resistivity survey (Conrad Schlumberger)

1927 First multi-electrode electrical survey in a wellbore

(in France)

1929 First electrical survey in California (also Venezuela,

Russia, India)

1931 First SP log, first sidewall core gun

1932 First deviation survey, first bullet perforator

1933 First commercial temperature log

1936 First SP dipmeter

1937 First electrical log in Canada (for gold in Ontario)

1938 First gamma ray log, first neutron log

1939 First electrical log in Alberta

1941 Archie's Laws published, first caliper log

1945 First commercial neutron log

1947 First resistivity dipmeter, first induction log

described

1948 First microlog, first shaped charge perforator

1948 Rw from SP published

1949 First laterolog

1952 First microlaterolog

1954 Added caliper to microlog

1956 First commercial induction log, nuclear magnetic

log described

1957 First sonic log, first density log

1960 First sidewall neutron log (scaled in porosity

units)

1960 First thermal decay time log

1961 First digitized dipmeter log

1962 First compensated density log (scaled in density/porosity

units)

1962 First computer aided log analysis, first logarithmic

resistivity scale

1963 First transmission of log images by telecopier

(predecessor to FAX)

1964 First measurement while drilling logs described

1965 First commercial digital recording of log data

1966 First compensated neutron log

1969 First experimental PE curve on density log

1971 First extraterrestrial temperature log Apollo 15

1976 First desktop computer aided log analysis system

LOG/MATE

1977 First computerized logging truck

1982 First use of email to transmit data via ARPaNet

(predecessor to Internet)

1983 First transmission of log data by satellite from

wellsite to computer center

1985 First resistivity microscanner

|

|

Many

newer tools have evolved from the older ones since 1985. Various

authors have specified alternate dates for these events - I have

usually chosen the earliest.

Since

the well files of the world are full of these ancient logs, we

must learn to glean what we can from them. This article is a self

contained coverage of how to analyze ancient logs to obtain shale

volume, porosity, water saturation, permeability, and average

reservoir properties. Methods that were once common in pre-computer

days have been excluded because we now have better ways to do

the same job.

ELECTRICAL

SURVEY (ES LOG)

ELECTRICAL

SURVEY (ES LOG)

The names and curve complement on older logs take a little study.

The table below lists the curves available and a useful name for

each. The illustrations following the table show typical log presentations

from this era. Presentations were far from standard and it may

take a little research to sort out who is where.

|

Schlumberger

and Lane Wells |

| Curves |

Units |

Abbreviations |

| |

|

|

| 16"

normal |

ohm-m |

R16,

SN, or RESS |

| 64"

normal |

ohm-m |

R64,

LN, or RESD |

| 18'

8" lateral |

ohm-m |

R18,

LT, or RLAT |

| *

32" limestone |

ohm-m |

R32

or RESM |

| spontaneous

potential |

mv |

SP |

| |

|

|

| OR |

|

|

| 10"

normal |

ohm-m |

R16,

SN, or RESS |

| 40"

normal |

ohm-m |

R64,

LN, or RESD |

| 15'

0" lateral |

ohm-m |

R18,

LT, or RLAT |

| spontaneous

potential |

mv |

SP |

| |

|

|

| Halliburton

and Welex |

|

|

| *

Point Source |

ohm-m |

Z,

or POINT |

| *

16" normal |

ohm-m |

2Z16",

SN, or RESS |

| *

57" normal |

ohm-m |

2Z57",

2Z5', SN, or RESS |

| *

64" normal |

ohm-m |

2Z64",

SN, or RESS |

| *

81" normal |

ohm-m |

2Z81",

2Z7', LN, or RESD |

| *

16' 0" lateral |

ohm-m |

3Z16',

LT, or RLAT |

| *

9' 0" lateral |

ohm-m |

3Z9',

LT, or RLAT |

| *

16' 0" inverse lateral |

ohm-m |

3iZ16,

LT, or RLAT |

| *

9' 0" inverse lateral |

ohm-m |

3iZ9',

LT, RLAT |

| *

32" limestone |

ohm-m |

4Z32"

or RESM |

| *

spontaneous potential |

mv |

SP |

| |

|

|

|

Note:

Halliburton inverse lateral is same electrode configuration

as Schlumberger lateral (blind spot at bottom of zone).

Lateral and normal spacings could vary. Point resistivity

is un-calibrated (even though a scale is shown) and

cannot be used quantitatively.

Restrictions:

Hole fluid should not be extremely resistive or extremely

conductive. Fresh muds, little invasion, hole size

constant are best.

Special

Features: No longer available. Replaced by generations

of induction logs. Lateral is not usually used for

quantitative work. 16" normal is used as a shallow

resistivity in conventional log analysis math, and

64" normal is used as a deep resistivity. Both

can be corrected manually for borehole and bed thickness

effects if desired. A "Limestone curve"

is a symmetrical lateral curve, usually 32 inch spacing.

Curve complement, electrode spacing, and log layout

varied considerably between service companies, location,

and era. All ES logs could have an amplified short

normal, usually 5 times more sensitive than main curve.

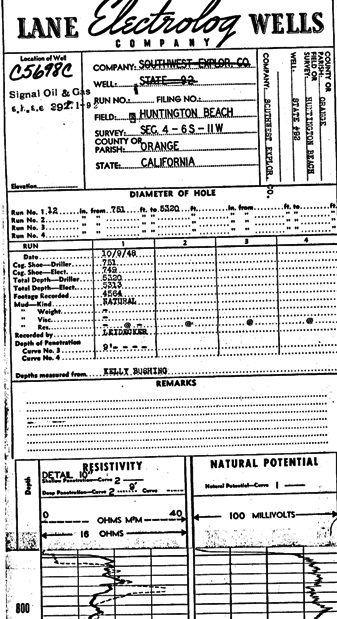

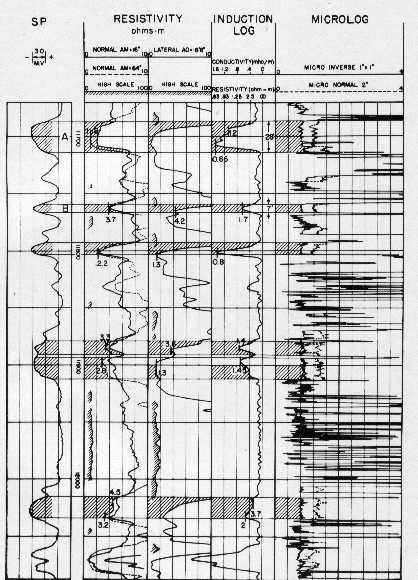

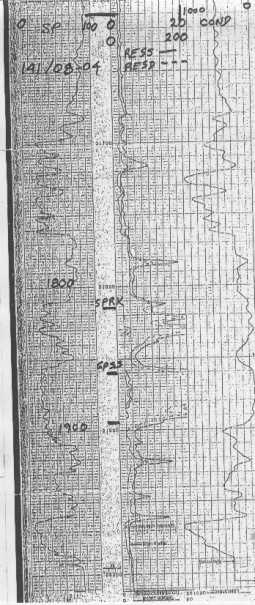

Schlumberger ES Log from 1953. Note neat scale

and curve name section (10inch and 40 inch normals

and 18'8" lateral)

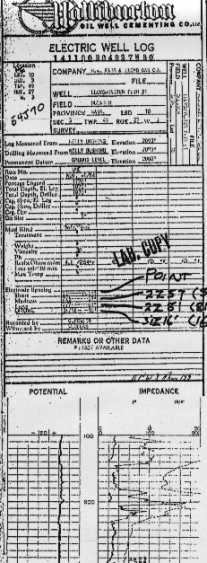

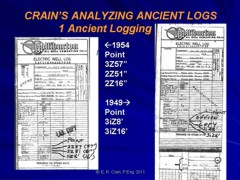

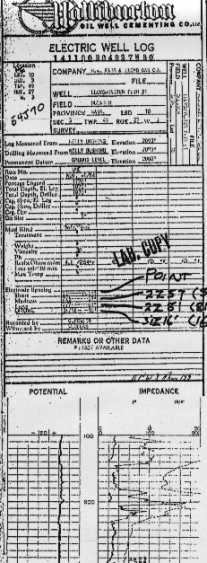

Halliburton ES logs from 1954 (left) and 1949

(right). Note curve names buried in body of header

or in depth track, odd scale on Point Resistivity,

and varying curve complement and spacings.

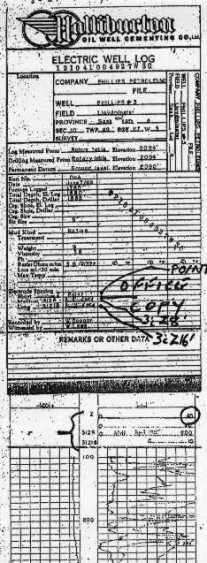

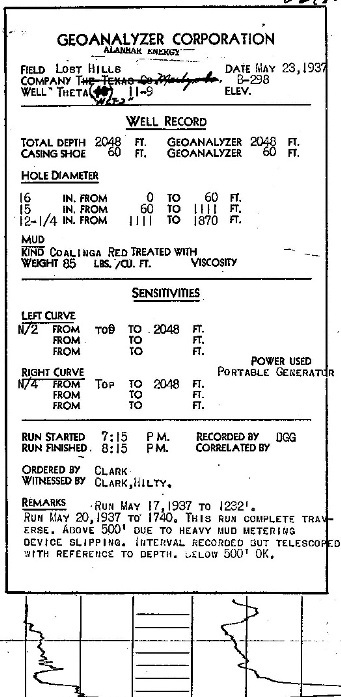

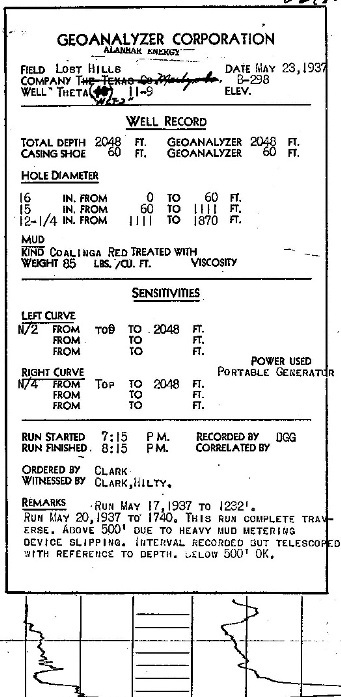

GeoAnalyzer Log from 1937 (left0 has unscaled SP in

left track and unscaled single-point resistivity in

righthand track. The curves were never named on the

log heading to avoid prosecution for patent

infringement. Lane Wells Electrolog from

1948 (right) has scaled SP in righthand track and 9

foot lateral with single-point resistivity in left

track. Lateral curve is scaled 0 to 40 ohm-m and

single-point is 16 ohms across the track, with no

zero value. Single-point resistivity cannot be used

quantitatively but is useful for bed boundaries and

relative resistivity values (high vs low).

ES

Normal curves are symmetrical; Lateral curves are not

and have a “blind spot” equal to the electrode

spacing AO (usually 18’8”). This blind spot occurs at

either the top or the bottom of a resistive reservoir, depending

on the electrode arrangement. ES

Normal curves are symmetrical; Lateral curves are not

and have a “blind spot” equal to the electrode

spacing AO (usually 18’8”). This blind spot occurs at

either the top or the bottom of a resistive reservoir, depending

on the electrode arrangement.

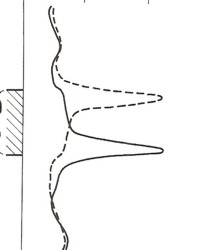

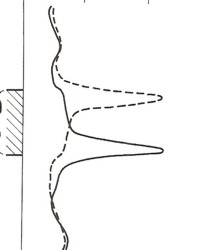

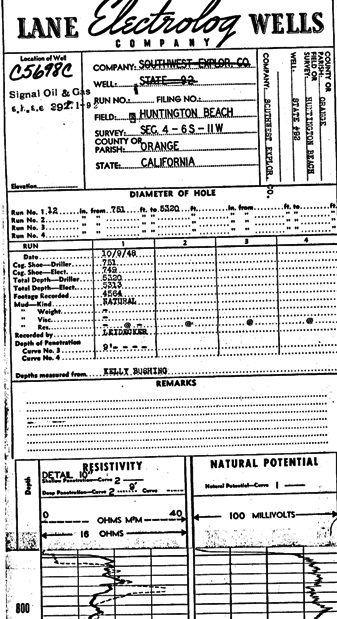

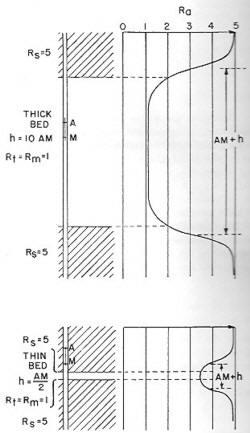

Lateral curve in resistive bed, solid line is original

electrode arrangement; dashed curve is inverse

arrangement with blind spot at base of reservoir

Note:

Halliburton inverse lateral is same electrode

configuration as Schlumberger lateral (blind spot at

bottom of zone). Lateral and normal spacings could vary.

Point resistivity is uncalibrated (even though a scale

is shown) and cannot be used quantitatively.

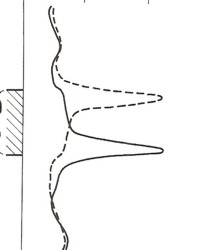

Bed boundaries on ES Normal curves must be adjusted for

the electrode spacing. Resistive beds appear too thin

and conductive beds too thick by an amount equal to the

AM distance (16”, or 64”) as shown below.

Bed boundaries on 64 inch normal ES curve

shows that bed thickness is short by a distance equal to

AM (64 inches) on resistive beds and too thick by 64

inches in conductive beds. Note that resistive beds

thinner than the tool spacing look conductive and vice

versa for conductive beds.

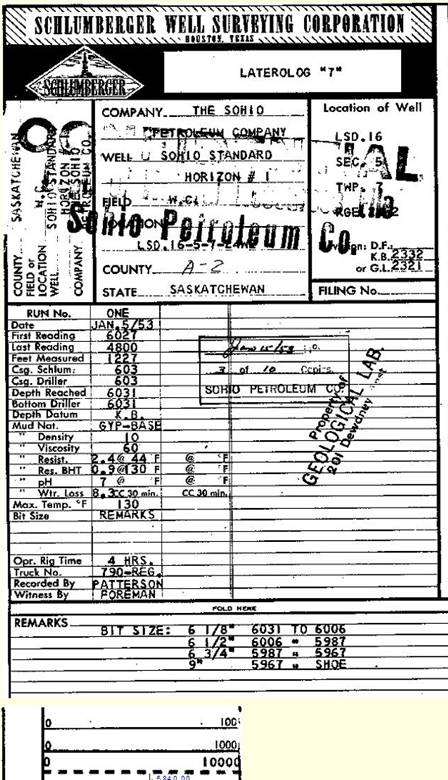

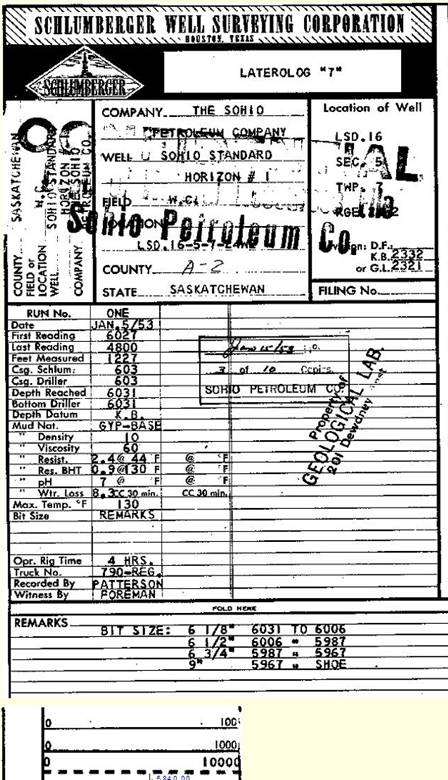

Laterolog (LL7 or LL3)

Laterolog (LL7 or LL3)

Curves Units Abbreviation

deep laterolog resistivity ohm-m RLL or RESD

* gamma ray API GR

* spontaneous potential mv SP

Restrictions:

Needs conductive mud, preferably very salty, The mud

resistivity should be less than formation resistivity.

SP is recorded 28 feet off depth - it may or may not

be spliced on depth - if it is, 10 foot and 50 foot

grid lines will not line up with rest of log. Note

hybrid scale on resistivity is common. Restrictions:

Needs conductive mud, preferably very salty, The mud

resistivity should be less than formation resistivity.

SP is recorded 28 feet off depth - it may or may not

be spliced on depth - if it is, 10 foot and 50 foot

grid lines will not line up with rest of log. Note

hybrid scale on resistivity is common.

Special

Features: Good in salty mud systems. No longer available.

Replaced by newer generations of laterologs. Also

called Guard Log or Focused Log. RLL curve is used

as a deep resistivity.

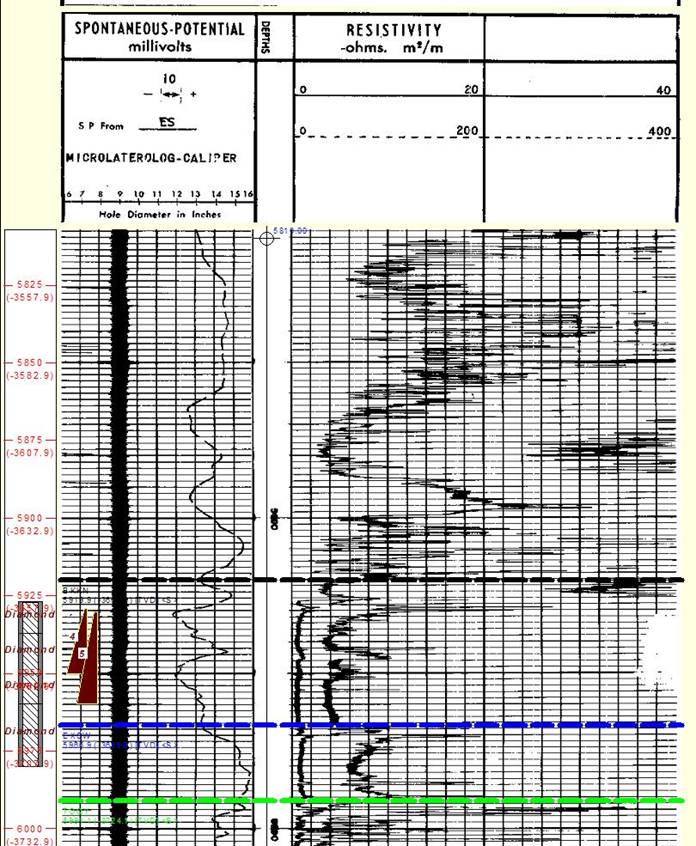

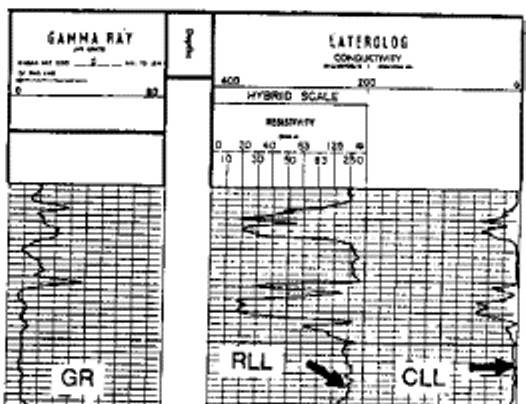

Laterolog with three linear resistivity scales

Laterolog with three linear resistivity scales

Laterolog with hybrid scale |

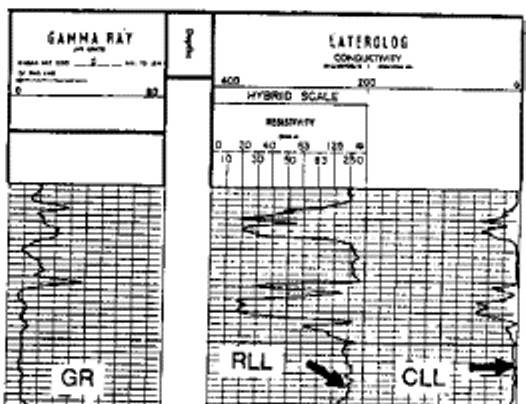

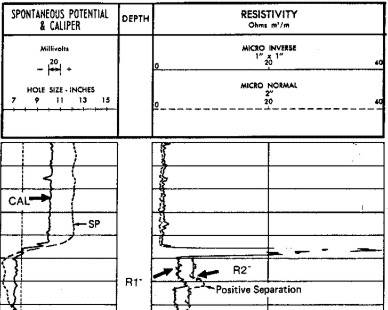

Microlog (MLC)

Microlog (MLC)

| Curves |

Units |

Abbreviation |

| |

|

|

| one

inch lateral resistivity |

ohm-m

R1 |

|

| two

inch lateral resistivity |

ohm-m |

R2 |

| *

caliper |

in

or mm |

CAL |

| *

gamma ray |

API |

GR |

Restrictions:

The MLC is severely affected by mud cakes thicker

than 2 inches, and by rough or large hole.

Special

Features: Still available. Combinable with microlaterolog.

The microlog and microlaterolog electrode pads are

mounted on opposing arms of the two-arm caliper linkage.

The microlog shows permeable zones by positive separation

of R1 and R2 - dashed curve reads greater than solid

curve - except in heavy oil and tar sands. Both tools

can be run separately if requested. Used primarily

in fresh mud. Can also be run with density log. R1

and R2 can be used as shallow resistivity (RESS) in

computer programs.

Microlog

showing positive separation Microlog

showing positive separation

(R2 > R1. dotted curve > solid curve) indicating

permeable zones.

Comparison of ES, IES, and MLC in sand - shale sequence

(shaded areas are relatively clean sandstones) - note separation

between curves on MLC. Colour the separation bright red and count

your net sand. Compare to net sand from SP or resistivity.

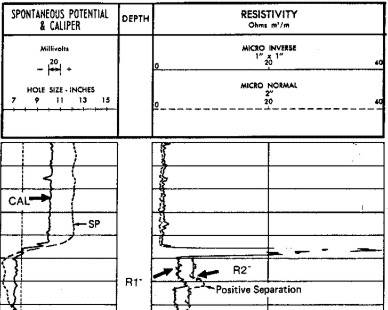

Microlaterolog (MLLC)

Microlaterolog (MLLC)

| Curves |

Units |

Abbreviation |

| |

|

|

| microlaterolog

resistivity |

ohm-m |

RMLL

or RESS |

| caliper |

in

or mm |

CAL |

| *

gamma ray |

API |

GR |

Restrictions:

The MLL is severely affected by mud cake thicker than

3/8 inch.

Special

Features: The microlog and microlaterolog pads are

mounted on opposing arms of the two-arm caliper linkage.

Both tools can be run separately if requested. Used

primarily in salty mud. RMLL can be used for a shallow

resistivity curve (RESS). Newer tools are proximity

log or micro-spherically focused log. Special

Features: The microlog and microlaterolog pads are

mounted on opposing arms of the two-arm caliper linkage.

Both tools can be run separately if requested. Used

primarily in salty mud. RMLL can be used for a shallow

resistivity curve (RESS). Newer tools are proximity

log or micro-spherically focused log.

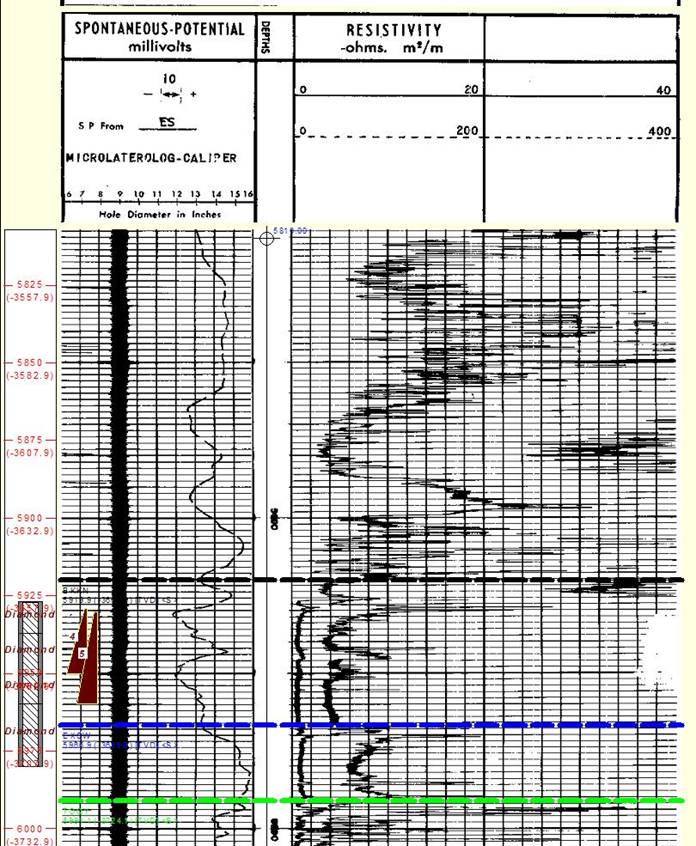

Microlaterolog on linear scale. Low resistivity

indicates porosity, shale, fractures or rough hole.

|

Gamma Ray Neutron (GRN)

Gamma Ray Neutron (GRN)

|

Curves |

Units |

Abbreviation |

| |

|

|

| *

neutron counts |

api

or cps |

NCPS

or NEUT |

| *

gamma ray |

api

or ug Ra equiv/ton |

GR |

| *

casing collar |

mv |

CCL |

Restrictions:

Neutron count rate affected by borehole fluid, hole

size, centering, and rock type. Porosity derivation

is therefore approximate and charts used must be specific

to the tool type and borehole environment. Restrictions:

Neutron count rate affected by borehole fluid, hole

size, centering, and rock type. Porosity derivation

is therefore approximate and charts used must be specific

to the tool type and borehole environment.

Special

Features: Gamma ray and neutron curves could be run

separately or combined on same log. Still used for

cased hole depth control. Replaced by compensated

neutron logs scaled in porosity units. This tool is

not normally used for quantitative porosity although

it is used when no other logs are available in the

well. Can be used in air, gas, or liquid filled holes

and can be logged through casing. Older logs were

very insensitive and suffered from large statistical

variations (poor repeatability).

|

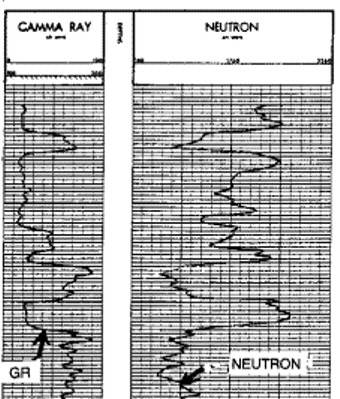

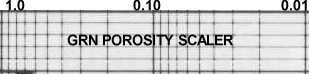

|

Logarithmic scaler for reading porosity from an un-scaled

neutron log. Draw vertical line on log at low porosity point (say

porosity = 0.05) and another line at high porosity point (usually

a shale - say porosity is 0.30). Align scaler between the two

lines, setting 0.05 on scaler at low porosity line, and 0.30 on

scaler on high porosity line. Skew scaler to obtain good fit.

Mark other porosity points on log. Enlarge or reduce scaler in

copier to fit smaller or larger logs. High and low porosity points

are a matter of good judgment tempered by core or log analysis

results from modern wells.

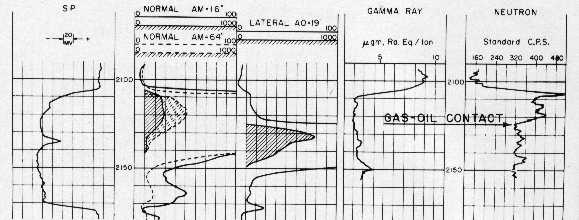

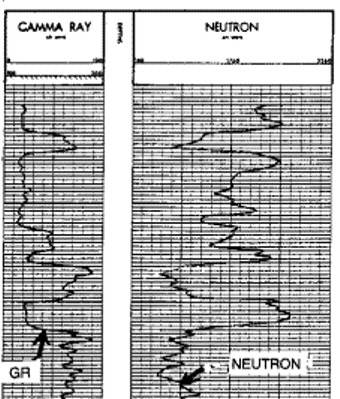

Typical GRN log with gamma ray (GR) and un-scaled neutron

log (NEUT). Use the scaler to draw a porosity scale on this log. Typical GRN log with gamma ray (GR) and un-scaled neutron

log (NEUT). Use the scaler to draw a porosity scale on this log.

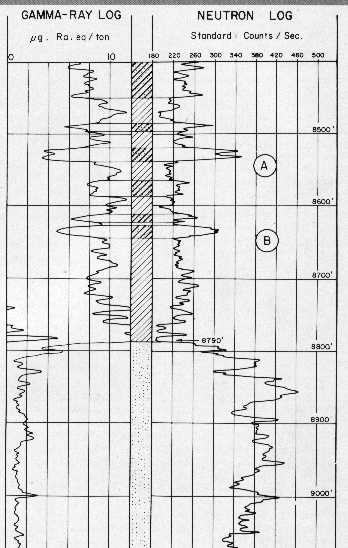

ES and GRN in gas over oil over water - Note 18'8"

blind spot on lateral curve, which explains why we

don't use it

for quantitative work in computer programs. The blind spot on

this lateral curve is at the

top of the zone. This is the original

electrode arrangement. It was soon inverted to put the blind spot

on the bottom of the zone (inverse lateral arrangement). Also

note backup scale on 16" and 64"

normal. Draw oil-water

contact on this log.

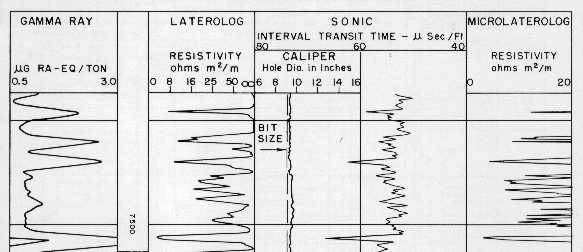

Laterolog (LL3), old style sonic (SL), and microlaterolog

(MLLC) - note hybrid resistivity scale on LL and thin porosity

streaks on MLLC not seen by other logs. Colour shale beds grey,

colour porous streaks red.

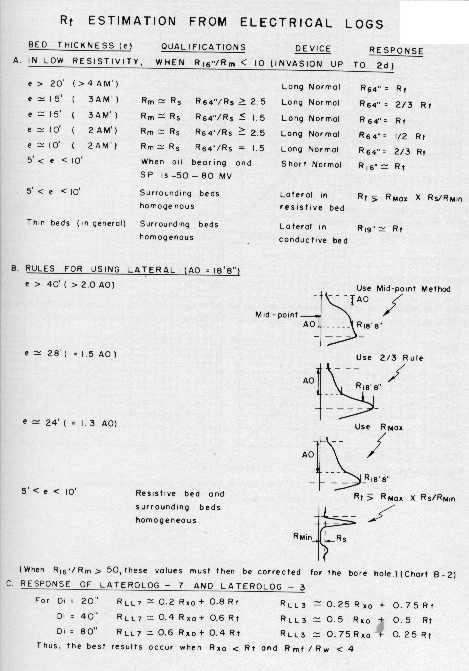

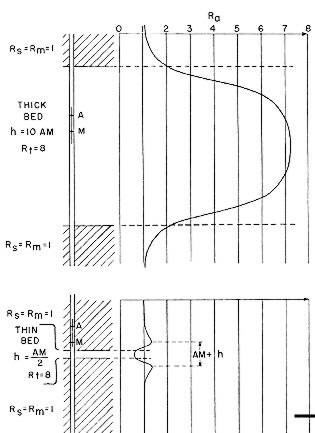

There

are special rules for picking the formation resistivity from the

long normal (RESD in this book, Rt in most of the literature).

These are empirical rules that work reasonably well and circumvent

the need for bed thickness and borehole corrections. The rules

are shown in the top half of of the illustration below..

Rules for estimating RESD (Rt) from long normal

(R64) and lateral (R18)

The

lateral curve on an ES log is not symmetrical and leaves a blind spot

at the top or bottom of a resistive bed (pay zones). The normal

practice in most parts of the world is to run the electrode

arrangement, called the inverse lateral, that puts the blind spot on

the bottom of the reservoir. The blind spot is the thickness of the

tool spacing, 18'8" for typical tools. The blind spot shows low

resistivity when it ought to show high resistivity, so the bottom 19

feet of the pay zone looks wet. If the other electrode arrangement

is used, the top 19 feet look wet, as illustrated at right.

Inverse lateral

(dotted curve) and original lateral (solid curve)

showing blind spot at bottom and top of reservoir respectively.

The

lateral curve can be used for handpicked data by following

the special rules shown above. Because

the lateral curve has a blind spot over the top or bottom of every resistive

zone, it cannot be used in computer aided log analysis unless it

is pre-processed with resistivity inversion software. However,

even this sophisticated software is a poor solution, as it tends to

draw a straight line through the blind zone, which you or I could do

faster and cheaper with a red pencil.

Shale Volume

Shale Volume

Shale is an imprecise term used to describe a rock composed of

clay, silt, and bound water. The clay type and silt composition

can vary considerably from one place to another. These can be

determined from appropriate cross plots of PE, thorium, and potassium

logs. The bound water volume varies with clay type, depth of burial,

and burial history. Some shales have not lost as much water as

others at similar depths and are called over-pressured shales.

Most shales are radioactive due to potassium and thorium, and

sometimes due to uranium.

In

ancient wells, the logs available for shale calculation are more

limited than in modern wells. The usual curves are gamma ray,

spontaneous potential, and shallow resistivity. Many ancient wells

have been re-logged through casing with gamma ray, neutron, and

thermal neutron decay (TDT) logs. There may even be modern logs

such as spectral gamma ray, sonic (compressional and shear), compensated

neutron, even resistivity. There may be a large number of suitable

curves to choose from. Density logging through casing is exceedingly

rare, so the density neutron crossplot method for shale volume

will be unavailable.

Shale

volume estimation is the first calculation step in a log analysis.

All other calculations depend on the shale volume being known

from this step.

STEP

1: Calculate shale volume from all available methods:

1: Vshg = (GR - GR0) / (GR100 - GR0)

2: Vshs = (SP - SP0) / (SP100 - SP0)

3: Vshr = (logRESS - logRMAX) / (logRSH - logRMAX)

NOTE:

Trim values between 0.0 and 1.0. If too many values fall outside

this range, check the clean and shale parameters. Do not calculate

methods which fail to pass all usage rules listed below.

STEP

2: Adjust gamma ray method for young rocks, if needed:

4: Vshc = 1.7 - (3.38 - (Vshg + 0.7) ^ 2) ^ 0.5

STEP

3: Take minimum of available methods:

5: Vsh = Min (Vshg, Vshs, Vshr, Vshc)

If SP is missing, flat, or noisy, we can calculate a

replacement SP. In hydrocarbon bearing sand shale sequences ONLY,:

6: SPpseudo = - 50 * log (RESS / RSH)

And in water zones ONLY:

7: SPpseudo = - 20 * log (RESS / RESD)

Both constants can be varied. Note the negative sign. By taking the

most negative answer from both equations, a continuous SPpseudo can

be generated without zoning.

RESD

must be from a 64 inch normal or a laterolog (or an old induction

log) which are symmetrical curves, and NOT from a lateral curve,

which has a blind spot on top or bottom of pay zones, depending on

electrode arrangement and spacing.

RESS is usually a 16 inch normal.

Neither technique is useful in salt mud systems.

USAGE

RULES:

USAGE

RULES:

Use uranium corrected gamma ray (CGR) in preference to uncorrected

GR

Do not use GR in radioactive sandstones or carbonates. Use Thorium

curve from NGT for radioactive sandstone, and uranium corrected

GR (CGR) curve for radioactive carbonates.

Do not use SP in fresh water formations, salt mud systems, high

resistivity zones, or in carbonates.

Do not use the nonlinear young rock model unless there is some

evidence that it is needed.

Resistivity method only works in hydrocarbon zones

On older gamma ray logs with no numerical scale, or logs scaled

in ug Ra eqiv/ton, choose an arbitrary scale to match offset logs

(eg 0 to 150 API units).

For SP logs, it is convenient to use a scale of 0 to 100 across

the track, or any arbitrary scale (minus 80 to plus 20 is widely

used).

GR and SP may need bed thickness corrections - see service company

chartbooks.

If

log analysis porosity is too low, calculated shale volume may

be too high (or vice versa).

The

shale in the zone may not have the same properties as nearby shales

seen on the log. Therefore, some adjustments to shale properties

might be necessary.

Shale

can be structural, dispersed, or laminated. Shale volume calculations

give averages over several feet. Different distributions will

affect resistivity, porosity, and permeability differently, so

these calculations will be affected by assumptions about distribution.

Special rules for laminated shaly sands are required and are covered

elsewhere.

Porosity

FROM ANCIENT

SONIC LOGS Porosity

FROM ANCIENT

SONIC LOGS

Ancient sonic

logs are those with one transmitter and 1 or 2 receivers, run from

about 1957 to about 1966 when borehole compensated (BHCS) tools were

put into service.

The Wyllie

equation is used to find total porosity. For a dual receiver tool:

8: PHIS = (DTC - DTCMA) / (DTCW - DTCMA)

OR For a single

receiver tool:

8a: PHIS = ((DTC /

SPAN) - DTCMA) / (DTCW - DTCMA)

Where:

SPAN = distance between transmitter and receiver (plus a fudge factor of

10 to 20% to account for the slower sound velocity of the mud

between transmitter and borehole wall and from borehole wall to

receiver). Calibrste to core or offset wells with better data.

NOTE: See CASE 1 below for lack of compaction correction.

Correct sonic porosity for shale

9: PHISSH = (DTCSH - DTCMA) / (DTCW - DTCMA)

10: PHIsc = PHIS - Vsh * PHISSH

11: PHIe = PHIsc

SPECIAL CASES

SPECIAL CASES

CASE 1: Correct

each layer for lack of compaction, ONLY IF DTCSH > 328 (Metric) or

DTCSH > 100 (English)

12a: KCP = Max(1, DTCSH / 100) English

Units (usec/ft)

OR 12b: KCP = Max(1, DTCSH / 328) Metric Units (usec/m)

OR 12c: KCP = PHIsc / PHItrue

13: PHIe = PHIsc / KCP

Where

PHItrue PHIcore or PHIe from

shale corrected density neutron complex lithology porosity model in

an offset well.

CASE 2: Correct

each layer for gas effect, ONLY IF PHIsc > PHItrue and gas is known

or suspected:

14 PHIe = PHIsc * KS

NOTE: It may be necessary to combine

Cases 1 and 2 to obtain a single correction factor.

Ancient

sonic logs are recorded in microseconds per foot.

The oldest tools are single receiver, recorded in microseconds The

total travel tine is usually too

high because of the travel time through the mud. Some present total

travel time from transmitter to receiver, so this value must be

divided by the tool spacing to get usec/ft. Ancient

sonic logs are recorded in microseconds per foot.

The oldest tools are single receiver, recorded in microseconds The

total travel tine is usually too

high because of the travel time through the mud. Some present total

travel time from transmitter to receiver, so this value must be

divided by the tool spacing to get usec/ft.

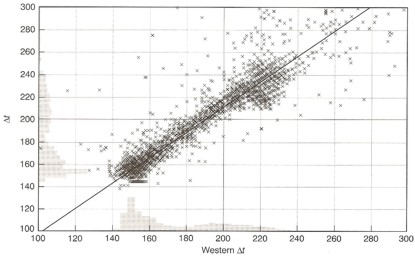

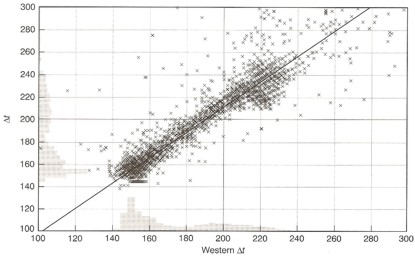

Comparison of

single receiver sonic (Y-axis) with 2-receiver sonic log, showing higher DTC of

single receiver version

Many ancient sonic logs give

unrealistic porosity values, others have chronic cycle skips, mostly

to high values.

Changes in borehole size also

cause spikes on the log, to both the high and low travel time

directions. These are not cycle skips, but are due to the unequal

travel time to each detector through the mud in the brehole.

Example of single

transmitter sonic log with spikes (crosshatched areas) caused by

variations in hole size. These should be edited or trimmed off

before using the log data for porosity calculations. Example of single

transmitter sonic log with spikes (crosshatched areas) caused by

variations in hole size. These should be edited or trimmed off

before using the log data for porosity calculations.

Porosity FROM anCiENT DENSITY logs

Porosity FROM anCiENT DENSITY logs

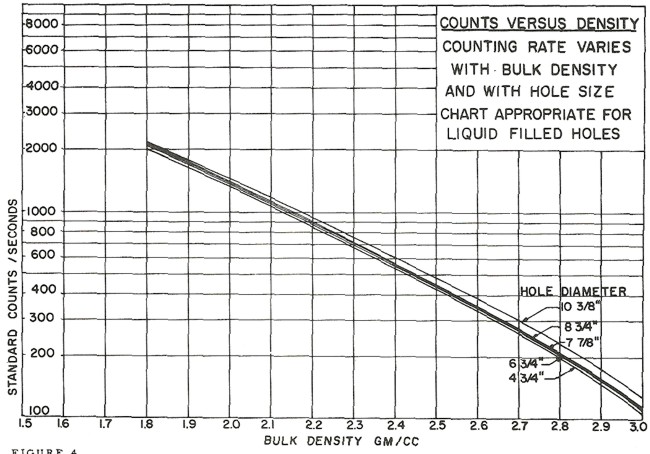

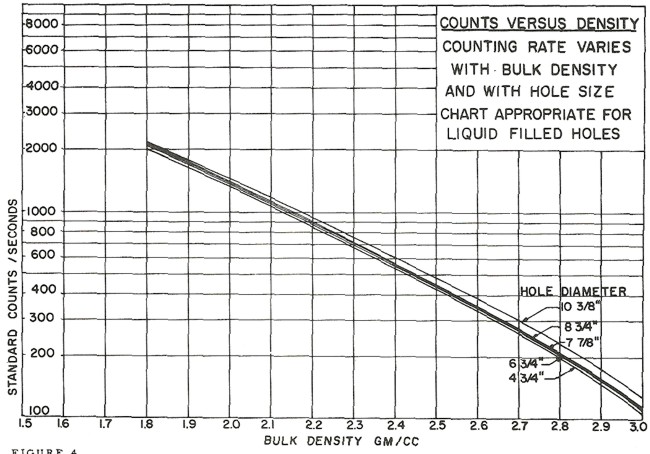

Ancient density logs

are recorded in counts per second. You get to work out

the transform to density using a semi-logarithmic High - Low

porosity technique as described for the neutron log. Here, high

count rate = low density = high porosity. Semi-log crossplots of count rate versus core density or core

porosity will calibrate the method. Charts for some specific tools

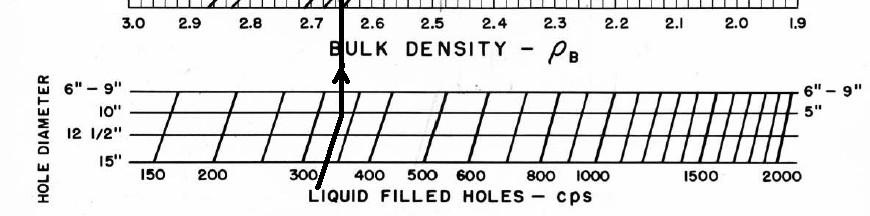

can be found in the literature, such as the one shown below.

Counts per second to density

transform for a Schlumberger PGT-A density tool. Each tool iteration

and each service company requires a specific chart. Density varies

with hole size mud weight, and , An equation for the 8 inch

borehole case is DENScps = -0.88 * LOG(CPS) + 4.71

13: PHID = (DENS - DENSMA) / (DENSW - DENSMA)

Apply density shale correction:

14: PHIDSH = (DENSH - DENSMA) / (DENSW - DENSMA)

15: PHIdc = PHID - Vsh * PHIDSH

These tools are severely affected by hole size, mud weight, mud cake

thickness, source type and strength, source detector spacing, and

detector efficiency. The High-Low calibration method compensates for

all these problems, but available charts do not. In the earliest

versions of these tools, the source strength decayed rapidly, so

count rates definitely need to be normalized on a well by well

basis.

Most density transforms never made it into

published chart books. This one did -

Schlumberger PGT-C or D density count rates to porosity. Additional

charts are available to correct for mud cake thickness and mud

weight, and for air-filled holes. The count rate charts appeared in

1966 chart books, well after they were no longer needed, and

disappeared after 1968. Most density count rate charts are

very hard to find unless you have a good supply of ancient chart

books from 1958 through 1968 - a 10 CD set of ancient chart books was published by Denver

Well Log Society and sold through

SPWLA.

An

alternate to the semi-log High-Low method was used with early

neutron and density logs. This

involves "relative count rate excursions" and service company charts

of these values versus the desired rock property (porosity,

density). The problem, of course, is that you need the chart unique

to each tool and sufficient patience to do the constructions. Below

is the instruction set developed by Lane Wells from their 1964

Technical Bulletin on their Densilog Tool.

Instructions for the "relative

deflection" method for transforming density log count rates to

density, from the 1964 Lane Wells Densilog Technical Bulletin.

Full size response charts are in the same book.

POROSITY FROM ANCIENT NEUTRON LOGS

POROSITY FROM ANCIENT NEUTRON LOGS

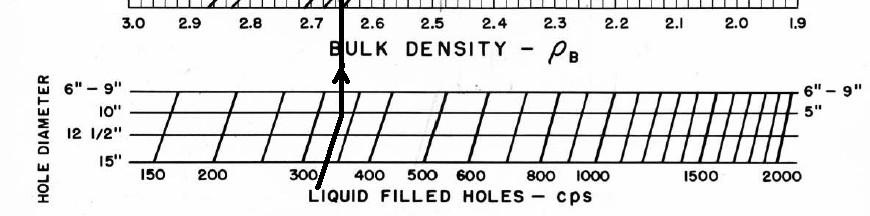

Old style gamma ray neutron (GRN) logs are un-scaled neutron logs

recorded in counts per second or API units. They are common in

ancient wells. The log carries a gamma ray curve (GR) in the left

hand track and a neutron curve (NEUT) in the right hand track.

No borehole or casing corrections have been applied to these logs.

Neutron log deflections to the left (lower count rate) represent

higher porosity.

A

large number of charts for specific tools, spacings, borehole

conditions and rock types were available from service companies,

such as the one shown below. These may no longer be

easily found today, and the semi-logarithmic approach described

below works well except in very low porosity .

GNT-F or G neutron porosity interpretation chart. Hundreds

of such charts exist for dozens of tools for a large range of

hole sizes, mud weights, and casing sizes. most are not

contained in conventional chart books. Some are available on the

Denver Well Log Society CD set sold by

SPWLA.

There were three source types used (RaBe, PuBe, and AmBe) and

several source - detector spacings (15.5 and 18.5 inches were

common), combined with hole size, mud weight, and casing

variations, leading to a plethora of transforms. Some service

companies didn't have a lot of faith in their charts - one used

the term "Strata Index" instead of "Porosity" on the Y-axis.

If

no appropriate chart exists, or if you don't believe in them, it is expedient to use the "High

porosity- Low porosity" method.

1.

Select a high porosity point on the log, usually a shale,

and assign it a porosity based on offset wells with scaled

logs or a local compaction curve. This is PHIHI.

2. Pick the count rate on the neutron log at

this point - this is CPSHI, even though it is a low numerical value.

3. Choose

a low porosity point on the log. Assign this a porosity value,

again based on offset scaled porosity logs or core porosity. This is PHILO.

Tight lime stringers or anhydrite are best but you need some

imagination if there are no truly low porosity streaks.

4. Pick

the corresponding count rate on the log. This CPSLO, even though

it is a larger number than CPSHI.

5. Plot these points on semi-log graph paper as shown

below. Read porosity for any other count rate from the graph.

Example of Porosity from Neutron Counts per

Second - no shale correction

To use this plot in a calculator or computer

instead of on a graph:

16: SLOPE = (log (PHIHI / PHILO)) / (CPSHI - CPSLO)

17: INTCPT = PHIHI / (10 ^ (CPSHI * SLOPE))

17: INTCPT = PHIHI / (10 ^ (CPSHI * SLOPE))

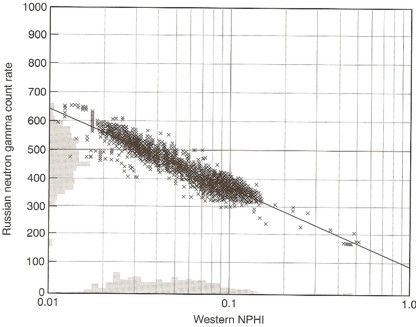

18: PHIn = INTCPT * 10 ^ (SLOPE * NCPS)

Correct scaled neutron porosity for shale effect

19: PHInc = PHIn – Vsh * PHINSH

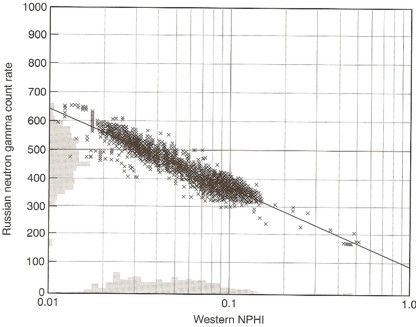

Semi-log

crossplot of count rate versus porosity for a group of Russian log

data

USAGE

RULES:

USAGE

RULES:

Use only if sonic and density log are unavailable or unusable.

Do not use in gas zones - very pessimistic results, correction

for gas difficult.

The neutron log corrected for shale is one of the least accurate

methods in shaly sands and should only be used if no other porosity

data is available. This is common for wells drilled prior to 1957

or for wells logged through casing or drill pipe.

To calibrate to core porosity, adjust PHIHI, PHILO, PHINSH or

Vsh to obtain a better match by trial and error. Appropriate crossplots

may assist.

Scaled

neutron logs are also common in ancient wells, having been run through casing sometime

after the original logs were run. They will have a GR curve and

a neutron porosity curve (PHIN in this Handbook), the latter may

have lithology, borehole, or casing corrections already applied.

If it does not have these corrections, service company charts

are used to apply the corrections. Read the log heading carefully

to determine what has already been done.

CAUTION:

In dolomite zones, many so-called compensated cased hole neutron

logs did not present a rational value for porosity. This appears

to have been fixed in recent years. Always compare results in

carbonates with offset open hole logs or core data.

Porosity

FROM ES and Micrologs

Porosity

FROM ES and Micrologs

There are a number of techniques for handling ancient logs like

the old electrical survey (ES) and microlog (MLC). The ES log

has 3 resistivity curves, the long normal or 64 inch normal (LN),

the short normal or 16 inch normal (SN), and the 18' 8" lateral

curve (not to be confused with a laterolog). The SN curve can

be used as a shallow resistivity log (RESS in this Handbook) and

the LN can be used as a deep resistivity (RESD in this Handbook).

The ES log also has a spontaneous potential (SP) curve used to

find shale volume or water resistivity in sand-shale sequences.

There

are hundreds of charts used to perform borehole and bed thickness

corrections to these curves. For typical fresh mud in an 8 inch

(200 mm) borehole in a bed thicker than 8 feet, these corrections

are small enough to be ignored. Charts for these corrections can

be obtained on request from service companies.

The

simplest porosity from resistivity method is to use the shallow

resistivity and assume that the flushed zone water saturation

is near 1.0.

20: PHIxo = (A / ((RXO / RMF@FT) * (SXO ^ N))) ^ (l / M)

USAGE

RULES:

USAGE

RULES:

RXO is taken equal to the 16 inch normal (R16 or SN) or the microlog

R1 value.

Use only if no other porosity log is available.

Not recommended in heavy oil or tar sands because SXO is low due

to lack of invasion by mud filtrate.

PARAMETERS

PARAMETERS

Sandstones A= 0.62, M = 2.15, N = 2.00

Carbonates A= 1.00, M = 2.00, N = 2.00

Water Zone SXO = 1.00

Oil / Gas Zone SXO = 0.70 - 0.90

Heavy Oil / Tar Sand SXO = 0.10 - 0.35 |

|

The

microlog has two very shallow resistivity curves, the 1 inch (R1

- solid line) and 2 inch (R2 - dashed line). This data can also

be used in the following:

21: IF R2 > R1 (dashed curve is right side of solid curve)

22: THEN PHIml = 0.614 * ((RMF@FT * KML) ^ 0.61) / (R2 ^ 0.75)

23: OTHERWISE PHIml = 0

USAGE

RULES:

USAGE

RULES:

Use only if no other porosity log is available.

Not recommended in heavy oil or tar sands because of lack of invasion

by mud filtrate.

PARAMETERS

PARAMETERS |

|

|

| Mud |

Weight |

KML |

| lb/gal |

kg/m3 |

frac |

|

8 |

1000 |

1.000 |

|

10 |

1200 |

0.847 |

|

11 |

1325 |

0.708 |

|

12 |

1440 |

0.584 |

|

13 |

1550 |

0.488 |

|

14 |

1680 |

0.412 |

|

16 |

1920 |

0.380 |

|

18 |

2160 |

0.350 |

|

Maximum Porosity Method

Maximum Porosity Method

In

ancient wells, there may be no porosity logs of any kind. In addition,

resistivity methods may be ineffective due to lack of invasion

(heavy oil) or thin bed effects. The maximum porosity method is

quite useful in shaly sands, but may not be helpful in a carbonate

sequence. In

ancient wells, there may be no porosity logs of any kind. In addition,

resistivity methods may be ineffective due to lack of invasion

(heavy oil) or thin bed effects. The maximum porosity method is

quite useful in shaly sands, but may not be helpful in a carbonate

sequence.

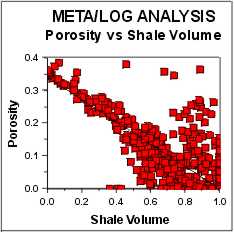

Choosing PHIMAX from a plot of Vsh vs PHIe from offset

well - high porosity at high Vsh on this plot is from bad

density data in rough borehole  . .

Calculate PHImx

24: PHImx = PHIMAX * (1 - Vsh)

If

there is no other porosity calculation method that works, then

PHIe = PHImx.

Bad

hole, bad cement, high shale volume, and statistical variations

can cause erratic results when a scaled or un-scaled neutron log

is used, Values of porosity from any method should be trimmed

by the following:

25: IF PHIe < 0

26: THEN PHIe = 0

27: IF PHIe > PHIMAX * (1 - Vsh)

28: THEN PHIe = PHIMAX * (1 - Vsh)

USAGE

RULES:

USAGE

RULES:

Use always to trim excessive porosity due to wet shales or bad

hole conditions.

Use as a porosity method in shaly sands.

This

material balance prevents the sum of shale volume, porosity, and

rock matrix from exceeding 100%, and prevents porosity in the

sand fraction of a shaly sand from reaching ridiculous values.

It is useful for estimating porosity in shaly sands where only

an SP or gamma ray log is available.

CAUTION:

Bear in mind that this approach provides a porosity value based

only upon the shale content and the analyst's assumed maximum

possible porosity. With offset well data for control this is not

a bad approach for wells with a very limited log suite. It is

often used in computer analysis of ancient logs. Because of its

gross assumptions, a warning note should be annotated on the results,

if the method is used in this manner.

Lithology Lithology

The third step in a log analysis is usually a lithology calculation.

The log suite in an ancient well does not provide data suitable

for such a calculation, unless some modern tools have been run

through casing (such as the dipole shear sonic with a compensated

neutron, or an induced gamma ray spectral log (GST) or equivalent.

In most cases, the lithology description comes from core and sample

descriptions, core analysis grain density, or log analysis in

offset wells.

Water Saturation

- CONVENTIONAL METHODS

Water Saturation

- CONVENTIONAL METHODS

All the usual water resistivity and water saturation

methods covered elsewhere in this Handbook can be used once shale

volume and porosity have been determined. You can chose from anyone

of more than 20 possibilities. I prefer to use the 64 inch Normal

curve in sand shale sequences, as it sees deep enough as a rule, has

sharp bed boundaries in fresh mud and has symmetrical curve shape.

In salt mud or any mud system with high resistivity rocks, use the

laterolog (not the lateral curve) as your deep resistivity. The

laterolog has about a 3 foot bed resolution compared to 5 feet for

the 64" Normal, so use the laterolog if you have a choice.

Prior

to about 1950, there were no laterologs, so you are stuck with ES

curves. In large boreholes or salty mud, environmental corrections

could be large and necessary. You will need appropriate service

company chartbooks or resistivity inversion software. I recommend

the latter, using SP and 16" Normal and the tool dimensions, to

correct the 64" Normal.

If porosity is still doubtful, try the model in the next Section.

Water Saturation and Porosity from Ratio Method

Water Saturation and Porosity from Ratio Method

When no porosity data is available, saturation can be obtained

by comparing the shallow and deep resistivity logs. This formula

is not shale corrected but the chart below is.

Calculate water saturation

29: SWrt = SXO * ((RXO / RESD) / (RMF@FT / RW@FT)) ^ (1 / N)

SWrt

becomes SWe if there is no other method available.

Calculate porosity

30: PHIrt = (A / ((RESD / RW@FT) * (SWrt ^ N))) ^ (l / M)

31: PHIxo = (A / ((RESS / RMF@FT) * (SXO ^ N))) ^ (l / M)

USAGE

RULES:

USAGE

RULES:

Use 64 inch normal or laterolog as RESD, use 16 inch normal or

microlog as RESS.

Do not use lateral as RESD.

Use only if no other porosity log is available.

Do not use in heavy oil or tar sands because SXO is difficult

to estimate.

See below for a graphical solution to this formula, with

additional shale correction if needed.

PARAMETERS

PARAMETERS

Sandstones A= 0.62, M = 2.15, N = 2.00

Carbonates A= 1.00, M = 2.00, N = 2.00

for water zone SXO = 1.00

for hydrocarbon zone with high porosity SXO = 0.60

for hydrocarbon zone with medium porosity SXO = 0.70

for hydrocarbon zone with low porosity SXO = 0.80

for heavy oil and tar sands, SXO = SW = 0.10 to 0.30 |

|

Graphical solution for Ratio method (with shale correction

from SP)

Modern Resistivity Inversion Software

Modern Resistivity Inversion Software

In the last few years, there has been a strong trend towards

inverse modeling of all forms of resistivity logs (including the SP curve). This

is due to the availability of computer code that performs an exact inverse solution

to model the resistivity, similar to that in use for focusing the array induction

log. By programming the tool geometry and extracting bed boundary data from a

shallow, thin bed resistivity log, the inverse model of deep resistivity can

be extracted from all older logging tools. This includes dual induction and dual

laterologs (which are still being run today) as well as the more ancient ES log.

An example of resistivity inversion results for a 18'8" lateral

curve (left) and an older style induction log (middle ) compared

to an array induction log (right). The SP is modeled in all

three cases, and may be the most useful curve of the bunch. The

modeling of the lateral curve gives a straight line through the

blind zone. Modeling the 64 inch normal would probably give more

realistic results.

Case Histories

Case Histories

Once shale volume, porosity, and water saturation are determined

from conventional or ancient methods, permeability, productivity,

net pay, and reserves are found by the normal methods outlined

elsewhere in this Handbook.

Calibrating Ancient to

Modern Logs (Shaly Sand)

Calibrating Ancient to

Modern Logs (Shaly Sand)

One way to test the techniques for ancient logs is to run the

math on a modern log suite and compare results to the same logs

after eliminating all the curves that would not have been available

in ancient times. In this well, we have conventional induction-electrical

and density-neutron logs in a heavy oil well. By assuming that

the induction resistivity is similar to a 64 inch normal and that

the only shale indicator is the SP, we can compare this "ancient"

log suite with the modern version in the identical rock/fluid

sequence using standard computer-aided log analysis.

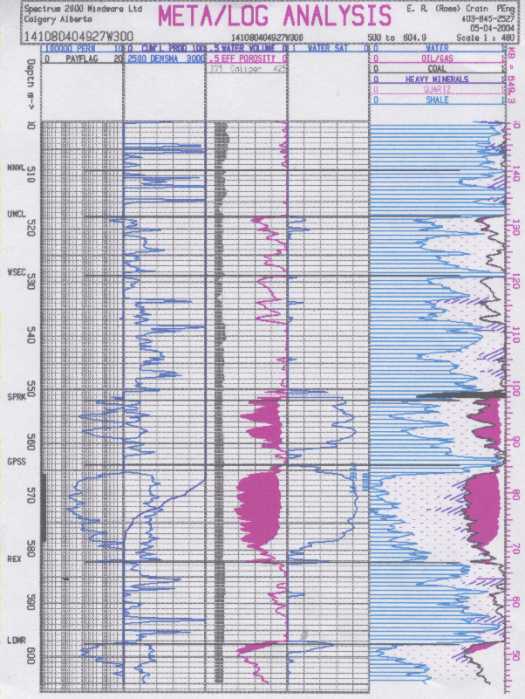

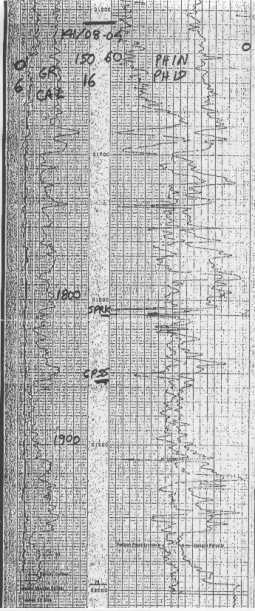

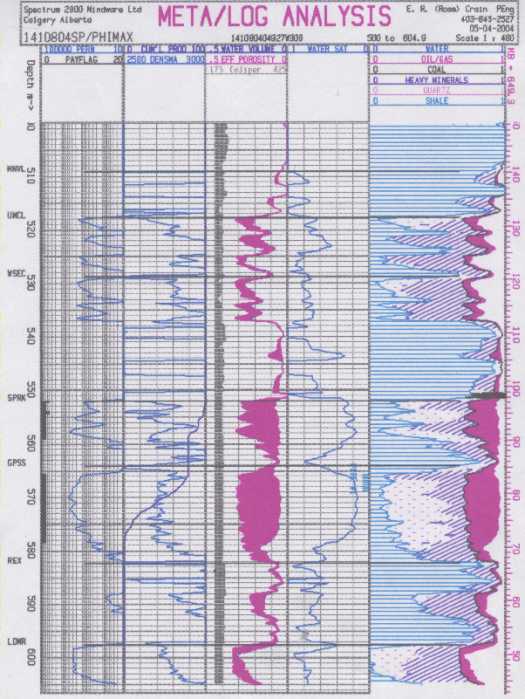

IES and CNL FDC for heavy oil case history 1978

Conventional log analysis using GR, CNL, and

FDC. Pick water contact in GP sandstone. Is there a contact in

the Sparky sandstone? Compare your answer to resistivity log.

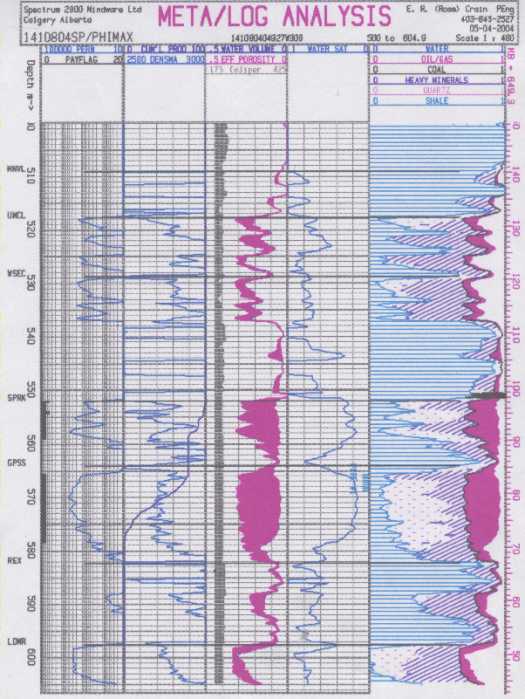

Same well computed with IES, SP, and PHIMAX

= 0.34. Compare to results in previous illustration.

Although

the induction resistivity is focused better than a 64 inch normal,

this example shows that the PHIMAX method is quite suitable in

a shaly sand sequence.

Lake Maracaibo (Shaly Sand)

Lake Maracaibo (Shaly Sand)

This case history is taken from "Quantitative Analysis of

Older Logs For Porosity and Permeability, Lake Maracaibo, Western

Flank Reservoirs, Venezuela" by E. R. (Ross) Crain, P.Eng.

Manuel Garrido, Craig Lamb, P.Geol., Philip Mosher, P.Eng. presented

at GeoCanada 2000, Calgary, AB, May 2000.

During

a project to analyze the log and core data on 150 wells in the

Western Flank Reservoirs offshore in Lake Maracaibo, we developed

a technique to determine accurate values of porosity, water saturation,

and permeability from old ES logs. The depositional environment

is a complicated sequence of superimposed fluvial channels, resulting

in many isolated channels that were not fully drained by nearby

wells. It was therefore necessary to obtain a quantitative reservoir

description for all wells in the project area, even if the log

suite did not lend itself to direct calculation with traditional

log analysis methods.

These

highly detailed reservoir properties from log analysis were augmented

by similarly detailed seismic and stratigraphic correlations,

and integrated together in a reservoir simulator to provide an

accurate historical and predictive model for production optimization.

We would not have been able to do this to a useable level if only

the wells with full porosity log suites were used.

The

method used requires calibration to conventional and special core

data and/or modern porosity log suites. Conventional core analysis

data, electrical properties, and capillary pressure data was provided

in paper form. This data was entered into a spreadsheet database

for processing and was placed in each well file for depth plotting

with the log data. Core data was depth shifted to match well log

depths.

Our

objective was to define a method that would utilize all available

log and core data while providing the most consistent results

between old and new well log suites. A detailed foot-by-foot analysis

was required to allow summations of reservoir properties over

each of many stratigraphic horizons.

Shale

volume (Vsh) was calculated from the gamma ray (GR), spontaneous

potential (SP), and deep resistivity (RESD) responses. The minimum

of these three values at each level was selected as the final

value for shale volume. A unique clean sand and pure shale value

for GR, SP, and RESD were chosen for each zone in each well. A

linear relationship was applied to the Vsh from GR. The resistivity

equation for Vsh is similar to the GR equation, but uses the logarithm

of resistivity in each variable.

Where

a full suite of porosity logs was available, effective porosity

(PHIe) was based on a shale corrected complex lithology model

using PEF, density, and neutron data. The method is quite reliable

in a wide variety of rock types. No matrix parameters are needed

by this model unless light hydrocarbons are present. Shale corrected

density and neutron data are used as input to the model. Results

depend on shale volume and the density and neutron shale properties

selected for the calculation. Therefore, the porosity from this

stage is compared to core porosity where possible, and parameters

are revised until a satisfactory match is obtained.

In

wells with an incomplete suite of porosity logs, we used a model

based on the shale corrected density log, shale corrected neutron

log, or the shale corrected sonic log. Again, a comparison with

core or nearby offset wells with a full log suite is necessary

to confirm shale and matrix parameters.

In

wells without any porosity logs, porosity was based on the shale

corrected total porosity model, where total porosity (PHIMAX)

was derived from offset wells with porosity logs or from nearby

core analysis. The equation used was PHIe = PHIMAX * (1 - Vsh).

This step was the most important contribution to the project as

it integrates all available data in all wells in a consistent

manner.

The

value for PHIMAX was derived from a map of the average of the

total porosity of very clean sands in modern or cored wells. The

map was inspected and a transform created which varied the PHIMAX

value from south to north through the project area. The effectiveness

of this method is demonstrated by the close match between core

and log analysis porosity in well LMA 11, shown in Figure 1. Another

way to see this relationship is in a crossplot of log derived

shale volume versus core porosity as in Figure 2.

In

modern wells, PHIMAX is also used to limit the porosity results.

This limit is needed because rough hole conditions or sonic cycle

skips can cause erroneous porosity values to be computed. PHIMAX

is computed as above, but modified by adding 0.03 to the result.

This higher value for PHIMAX prevents the reduction of those few

legitimate porosity results which are slightly higher than usual

on the logs.

From

this stage onward, both old and new wells were treated identically,

with water saturation, permeability, and mappable reservoir properties

being derived in a uniform and consistent manner.

Water

resistivity (RW) was varied with depth to account for the temperature

gradient over the computed interval. These values were confirmed

by the obvious water zones in the lower sands in a number of wells.

Care must be taken to segregate swept zones from original water

zones when checking the RW value. Swept zones show residual oil

on log analysis of between 20 and 60 percent. Back calculation

of RW in a swept zone will lead too high a value for RW.

Water

saturation (Sw) was computed with a shale correction using the

Simandoux equation and with the Waxman-Smits equation. Both equations

reduce to the Archie equation when shale volume is zero. Simandoux

and Waxman-Smits methods gave very similar results in this project

area. The resistivity curves used were the long normal from ES

logs, the deep induction, or the deep laterolog.

The

shale resistivity (RSH) needed for these equations was chosen

by observation of the logs and crossplots. RSH was varied from

well to well to account for differences in response between electrical

logs, induction logs, and laterologs in shale. Resistivity anisotropy

and hole size or mud resistivity effects cause these differences.

The range of values used is small, between 4.0 and 5.0 ohm-m.

Values

of A, M, and N of 1.00, 1.80, and 2.00 were input, based on special

core analysis crossplots. The effect of overburden pressure on

M and N was compared to non-overburden data on the plots where

such data was available. The regression lines for M were pinned

at A = 1.0 because the free regression lines vary too much, due

to the small range in porosity of the core plugs.

Saturation

results were confirmed by comparison to porosity vs capillary

pressure water saturation crossplots derived from the special

core data (Figure 3). When this data is missing in a project area,

it is very difficult to refine the saturation calculation. If

a mismatch does occur, the electrical properties and/or RW and

temperature data must be reviewed and modified if possible, to

obtain a better match to capillary pressure data.

Zones

swept by production from older offset wells are evident on all

newer wells in this project. These zones should not be confused

with the original water zones. Swept zones will produce water

if perforated, but contain 20 to 60 percent residual oil. On raw

logs, the difference in resistivity between a swept zone and an

original water zone may be very small (eg 0.4 vs 0.2 ohm-m in

an extreme case).

An

irreducible water saturation (SWir) was calculated based on a

curve fit to the capillary pressure data, using the following:

IF PHIe > 0.10 THEN SWir = 0.20 / (PHIe - 0.10) ELSE SWir =

1.00. This equation represents a skewed hyperbola through the

porosity vs saturation data.

SWir

was also limited by the Simandoux water saturation such that SWir

could not exceed the Simandoux result. This means that SWir is

the lower of the actual log derived water saturation and the SWir

calculated above. The swept zones are most easily seen on depth

plots by comparing SWir to the Simandoux or Waxman-Smits water

saturation. Where large differences occur, the zone is likely

swept.

Crossplots

of core porosity vs core permeability (Figure 4) gave: Perm =

10 ^ (23.0 * PHIe - 3.00). Detailed crossplots of each zone in

each well, composite plots of each zone for all wells, and a composite

plot of all zones in all wells were made. Differences between

zones and between wells were negligible. Regression analysis to

predict permeability from porosity produces a good average permeability

within a zone. It may not always honour every peak and valley

seen on real cores.

Crossplots

of permeability vs capillary pressure water saturation were also

made. These show a semi-logarithmic straight line relationship.

The plots show that water saturation and permeability are closely

related. High water saturations indicate fine grained, more poorly

sorted, lower permeability, and often shalier zones.

Crossplots

of permeability vs residual oil saturation also show a semi-logarithmic

straight line relationship with higher permeability having lower

residual oil saturations. This is a normal occurrence, and allows

a check of the residual oil saturation seen in swept zones by

log analysis.

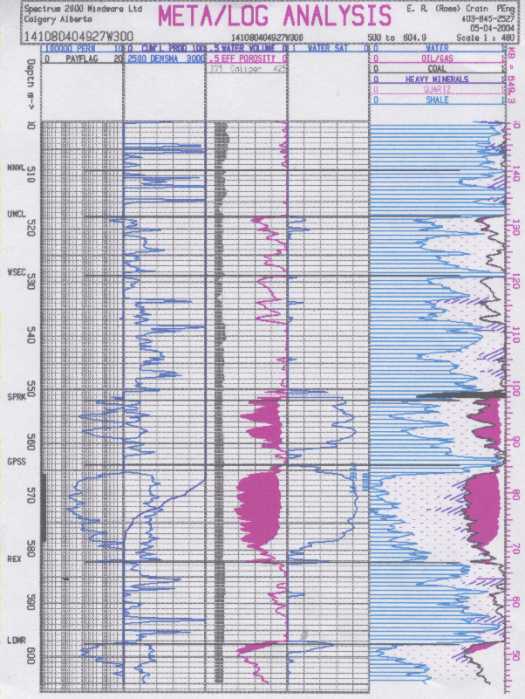

Results of analysis on ancient logs, Lake Maracaibo,

Venezuela. Compare core porosity (black curve in left track) with

porosity from PHIMAX (red curve).

On

older wells, previous work used a two step correlation of oil

saturation (So) times porosity (PHI) to the short normal resistivity

(SN) and mud resistivity (RM), of the form:

1.

ln(RT/RM) = A + B * ln(SN/RM)

2. SOPHI = C + D * ln(RT)

This

method was developed by Dr Ovidio Suarez and is documented in

internal reports provided by the client. The parameters A through

D were derived from correlations with hydrocarbon pore volume

(HPV) estimated from core analysis. The method does not account

for borehole effects, invasion, or variations in grain size, sorting,

or shaliness, all of which influence HPV from this type of correlation.

It also does not generate a porosity value, so results cannot

be compared easily to core data and cannot be used to calculate

permeability. Large differences in results between adjacent wells

were noted, leading to the conclusion that these inconsistencies

should be addressed in our new work.

In

the porosity track of Figure 37.17 (above), the green line is

porosity from SOPHI based on the SWe derived in our study: PHIrt

= SOPHI / (1- SWe). This well shows a good agreement between the

two methods but others do not, because the short normal is not

always a good indicator for RT.

It

should be noted, however, that at the time the method was invented,

it was the best approach available for un-cored intervals, since

modern porosity indicating logs had not yet appeared on the scene.

The

results of this study will lead to a significant change in original

oil-in-place compared to the value determined from a strict use

of the prior petrophysical analysis. In addition, all by-passed

pay zones are identified and can become targets for specific in-fill

wells. The reservoir simulation based on this new reservoir description

will have greater predictive power and will be easier to history

match because both reservoir volume and flow capacity are better

defined.

|

Restrictions:

Needs conductive mud, preferably very salty, The mud

resistivity should be less than formation resistivity.

SP is recorded 28 feet off depth - it may or may not

be spliced on depth - if it is, 10 foot and 50 foot

grid lines will not line up with rest of log. Note

hybrid scale on resistivity is common.

Restrictions:

Needs conductive mud, preferably very salty, The mud

resistivity should be less than formation resistivity.

SP is recorded 28 feet off depth - it may or may not

be spliced on depth - if it is, 10 foot and 50 foot

grid lines will not line up with rest of log. Note

hybrid scale on resistivity is common.

Special

Features: The microlog and microlaterolog pads are

mounted on opposing arms of the two-arm caliper linkage.

Both tools can be run separately if requested. Used

primarily in salty mud. RMLL can be used for a shallow

resistivity curve (RESS). Newer tools are proximity

log or micro-spherically focused log.

Special

Features: The microlog and microlaterolog pads are

mounted on opposing arms of the two-arm caliper linkage.

Both tools can be run separately if requested. Used

primarily in salty mud. RMLL can be used for a shallow

resistivity curve (RESS). Newer tools are proximity

log or micro-spherically focused log. Restrictions:

Neutron count rate affected by borehole fluid, hole

size, centering, and rock type. Porosity derivation

is therefore approximate and charts used must be specific

to the tool type and borehole environment.

Restrictions:

Neutron count rate affected by borehole fluid, hole

size, centering, and rock type. Porosity derivation

is therefore approximate and charts used must be specific

to the tool type and borehole environment. Ancient

sonic logs are recorded in microseconds per foot.

The oldest tools are single receiver, recorded in microseconds The

total travel tine is usually too

high because of the travel time through the mud. Some present total

travel time from transmitter to receiver, so this value must be

divided by the tool spacing to get usec/ft.

Ancient

sonic logs are recorded in microseconds per foot.

The oldest tools are single receiver, recorded in microseconds The

total travel tine is usually too

high because of the travel time through the mud. Some present total

travel time from transmitter to receiver, so this value must be

divided by the tool spacing to get usec/ft.

17: INTCPT = PHIHI / (10 ^ (CPSHI * SLOPE))

17: INTCPT = PHIHI / (10 ^ (CPSHI * SLOPE))