|

MUD LOGGING BASICS

MUD LOGGING BASICS

Mud logging, also known as

hydrocarbon well logging or gas logging, entails gathering qualitative and

semi-quantitative data from hydrocarbon gas detectors that record

the level of natural gas brought up in the mud. Chromatographs are

used to determine the chemical makeup of the gas.

Other properties such as drilling rate, mud weight, flowline temperature,

oil indicators, pump pressure, pump rate, lithology (rock type) of

the drilled cuttings, and other data are recorded. Sampling the drilled cuttings,

usually under the direction of the wellsite geologist,

must be performed at predetermined intervals.

The main purpose is to identify all

hydrocarbon indications from the rock samples and from the oil and

gas entrained in the drilling mud. Gas detected in the mud can be

interpreted to be:

1. liberated gas

2. recycled gas

3. produced gas

4. contamination gas

5. trip gas

Only liberated gas indicates a possible prospect; the others merely

confuse the analyst. This data, combined with the gas composition

determined from a chromatograph, assists in the location of oil and

gas zones as they are penetrated. The breakup of the gas shows into

these categories reduces the chance of misinterpretation of a gas

kick on the mud log.

Another important use of these logs

is well safety, since overpressured zones, lost circulation, and

gas kicks will be recognized quickly and remedial action taken.

Total gas in the mud is measured in

units of parts per million, but does not represent the actual

quantity of oil or gas in the reservoir. Total gas is separated in a

chromatograph. The most common gas component is methane (C1). Heavier

hydrocarbons, such as C2 (ethane), C3 (propane), and C4 (butane)

may indicate an oil or a "wet" gas zone. Heavier molecules, up to C7

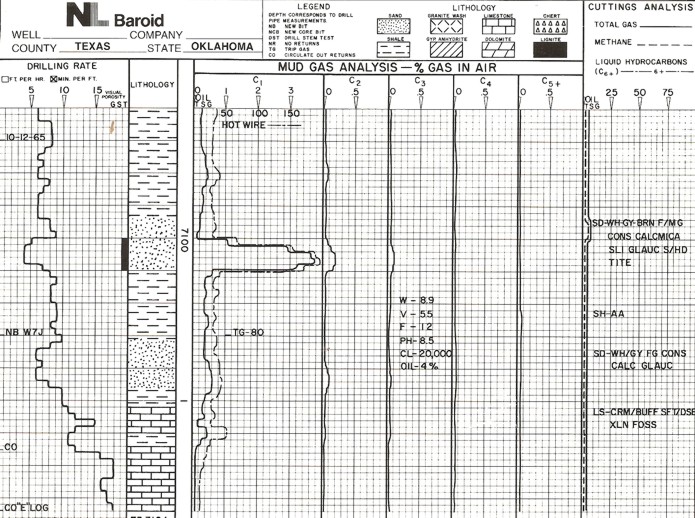

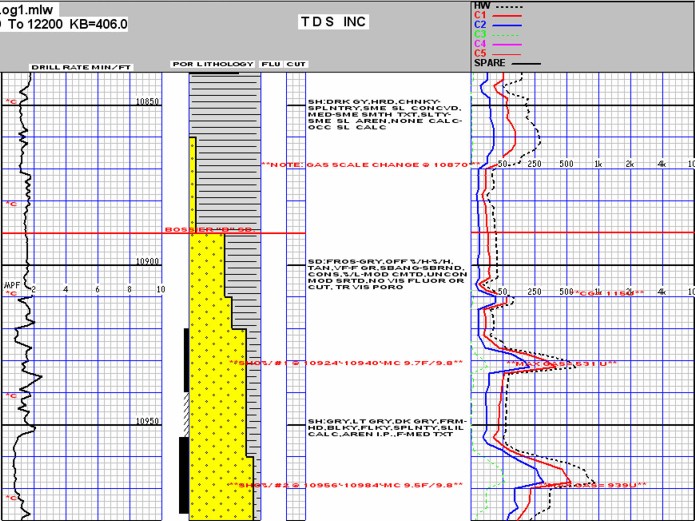

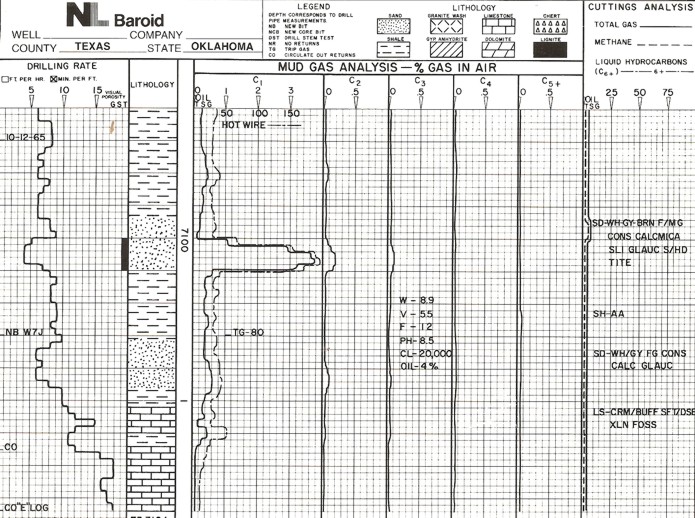

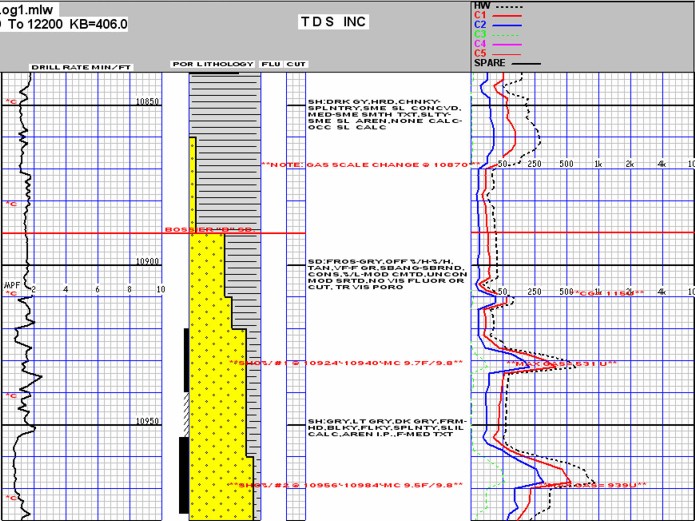

may be recorded. An example of a sample description log

with the gas mud log is shown below.

Modern mud log with drilling mechanics, sample descriptions, and mud

gas readings, showing two

potential gas zones.

Gas in the mud

system may indicate the penetration of either an oil or a gas

reservoir. The first objective is to detect the presence of the gas

with some form of total gas detector. The second step is to break

down the gas into its components with a gas chromatograph to see if

the gas comes from an oil or gas show.

For many years the simple hotwire, or as it is properly called,

catalytic combustion detector, has been the cornerstone of all gas

detection service. This device was the first mechanical replacement

for canaries in mines and is characterized by its simplicity and

reliability.

Several other detecting devices have been utilized from time to time

including the mass spectrometer, infrared analyzers, thermal

conductivity, and gas chromatographs. Regardless of which gas detecting instrument is used,

they are all limited by the amount of gas in the mud that can be

extracted and fed into the instrument.

If gas is seen on the log in quantities larger than the average

background, the question arises, "Is this a significant increase and

does it indicate a gas or oil zone?" Similarly, "How much

fluorescence in the cuttings indicates an oil zone?" The simple and

quick answer to both of these questions is, "We don't know, yet!"

Generally

speaking, extremely dry gas should give mostly C1 and not much C2, C3, or C4.

If ratios are presented on the log, each of C1/C2, C2/C3, C1/C4, and

C1/C5 will be greater than 50. Wetter gas will have ratios between

20 and 50. Oil zones will have ratios between 2 and 20. Local

knowledge should be used to refine these cutoffs. Generally

speaking, extremely dry gas should give mostly C1 and not much C2, C3, or C4.

If ratios are presented on the log, each of C1/C2, C2/C3, C1/C4, and

C1/C5 will be greater than 50. Wetter gas will have ratios between

20 and 50. Oil zones will have ratios between 2 and 20. Local

knowledge should be used to refine these cutoffs.

Spectroscope waveforms on computerized gas

mud logging unit (Illustration courtesy

of

Petro Log

International, Inc.

Usually,

there is enough empirical control from offset well histories to make a positive interpretation,

but there are so many variables involved that

this is not always possible immediately. After drilling is completed, the mud

log, sample log, open hole logs, and drill stem tests are used to

come to a final analysis.

These results are used on the next hole in

the same area as guides to more immediate interpretation on that

well. To achieve the best possible interpretation, it is vital to

integrate all of these tools at the very earliest point in the

evaluation process. Integration of all the petrophysical data is the

key to success.

To be useful, any log must be calibrated. Mud logs are no exception,

and most modern mud logs have been calibrated to a local or API

standard. However, many older

logs in the well file have not. This makes it even more difficult to

determine what the gas kicks mean.

LAG TIME

LAG TIME

Depth information is obtained from the driller's log, which records

depth versus the time of day. However, these depths cannot be used

directly. We wish the mud log data to be presented at the depth of

the drill bit, but the mud log measurements are made at the surface.

The time it takes for the mud to move from the bit to the surface

must be accounted for in positioning samples and gas kick data on

the log. This time is called the lag time and depends on the

velocity of the mud in the annulus between the drill pipe and the

rock. This in turn depends on the mud pump speed and displacement,

which are usually constant

for reasonable periods of time.

The lag time can

vary from a few minutes in an air drilled hole, to hours in a deep

mud filled hole. If lag time is much shorter than expected or

multiple lags are found, it usually means a leak in the drill pipe

which must be repaired immediately. The most reliable method of

establishing the lag time is to use a tracing material such as oats,

corn, paint, or calcium carbide. Carbide will produce a bubble of

acetylene gas. Typically, a sample of tracing material is introduced

into the drill pipe during a connection and circulated down through

the bit jets and back up the annulus. The use of calcium carbide as

a lag tracer has a secondary benefit. It permits verification that

the entire gas detection system is functioning. Since it is

necessary for the gas detector to extract, pump to the logging unit,

and sense the acetylene gas, it verifies the integrity of the entire

system.

This is only part of the story, as the time it takes the tracer to

go down the inside of the drill pipe must first be calculated from

the pump displacement, pump speed, pipe diameter, and pipe length.

The calculated downward time is deducted from the total measured

time to find the lag time.

GAS

DETECTION METHODS GAS

DETECTION METHODS

The total gas detector provides the basic quantitative indication as

to how much gas is being extracted from the drilling mud by the gas

trap. Total gas detection and analysis equipment in use throughout

the world

incorporates one of two standard detectors, the catalytic filament

detector, also called a hotwire detector, and the hydrogen flame ionization

detector.

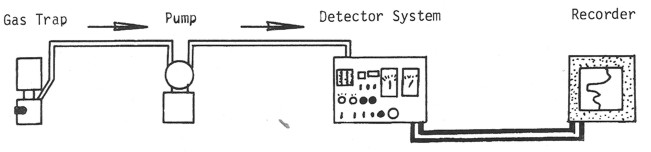

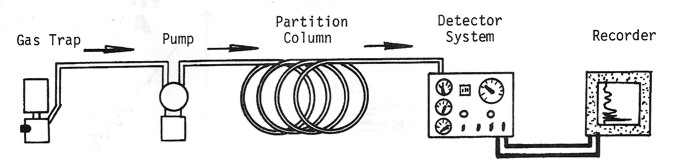

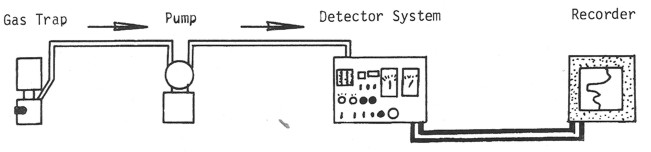

Schematic diagram of a mud gas detection system for total gas.

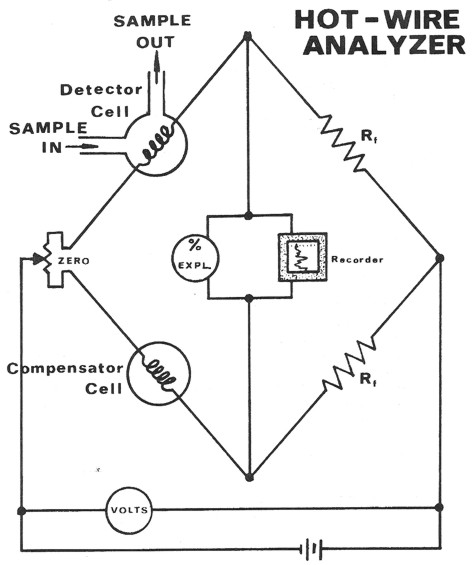

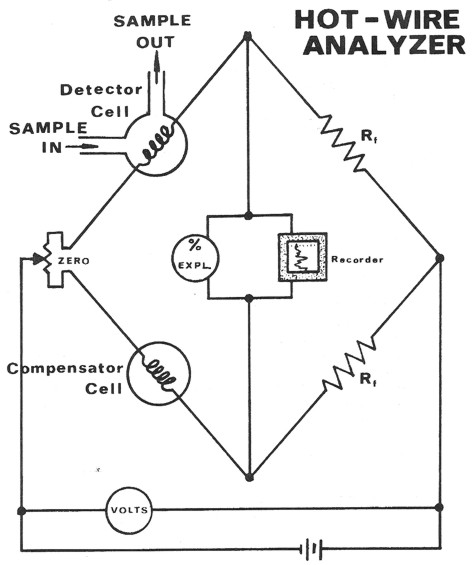

The hotwire operates on the principle of catalytic combustion of

hydrocarbons in the presence of a heated platinum wire at gas

concentration below the lower explosive limit. The increasing heat

due to combustion causes a corresponding increase in the resistance

of the platinum wire filament. This resistance increase is measured

through the use of a Wheatstone bridge circuit and recorded as

"units of gas".

The common hotwire detector responds to all combustible gases. It is

limited in its range since there must be sufficient oxygen present

in the sample mixture to enable all of the hydrocarbons present to

be catalytically oxidized by the platinum filament.

Schematic diagram of hotwire gas detector

The hydrogen flame ionization detector functions on the

principle of hydrocarbon molecule ionization in the presence of a

very hot hydrogen flame. These ions are subjected to a strong

electrical field resulting in a measurable current flow, which is

then amplified and recorded as "units of gas".

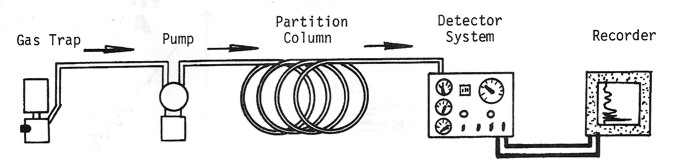

Detailed analysis of the hydrocarbon mixture is usually performed by

a gas chromatograph. The principal difference between a total gas

detector and a gas chromatograph is the partition column, which

breaks the gas stream into its component parts.

Most oilfield gas chromatographs are rapid sampling, batch

processing instruments that provide an accurate proportional

analysis of the paraffin series of hydrocarbons from methane through

pentane.

Occasionally, special features are built into chromatographs to

enable them to identify and measure hydrogen and various air

components. The information produced by the chromatograph is

reported in units or in mole percent of each component of the gas

detected.

Schematic diagram of gas spectrometer, showing retention chamber to

segregate the gases.

Gas chromatograph columns vary in design, but have several

characteristics in common. They start with a long, small diameter,

metal tube which is filled with a particulate material. This filling

material is referred to as the solid phase or support phase. Its

purpose is to provide a large surface area within the column. In

many instances, a liquid phase is laid down over the surface of each

of these grains or particles in order to increase its surface

activity. It is desirable to have highly active surface

characteristics so that there is a strong attraction between the

various gas molecules and the surface of the support material.

The degree of attraction between the active surfaces of the column

and the different gases passing through varies as a result of

different physical and chemical characteristics. By selecting the

proper column, it is possible to separate almost any suite of gases.

Typically, oilfield chromatographs are designed to separate the

paraffin series of hydrocarbons at room temperature, using air as

a carrier.

The carrier gas applies the energy required to

keep the molecules of a gas mixture moving through the column. It

flows at a constant rate. Since each different molecule is

attracted in different degrees to the the surface active material in the

column, they will be propelled at different rates.

The time of transit for a given gas to pass through a particular

column under specified flow conditions is referred to as the

retention time. Retention time is the principle method of

identifying various gases in a mixture. Since each column has

different permeability characteristics, it is necessary that known

gas standards be passed through the column and that their retention

times be established if this analytical method is to be reliable.

The partition column separates a slug of gas into its components by

delaying the passage of the heavier compounds. The amount of each

component must still be detected by devices similar to the total gas

detectors, or other more elaborate devices. Some are as

simple as measuring the gravity of the gas coming out. Other common

types involve measuring combustion ratios, thermal

conductivity, and carbon content.

Since the retention times and response characteristics of each

chromatograph are unique, it is necessary that standard blends of

calibration gases be introduced into the instrument on a regular

basis to establish the instrument's response characteristics.

Once the response graph has been established for a particular

instrument, then raw readings can be easily entered into the graph

and read out in percent. With modern computer controlled equipment,

the conversion factors are applied automatically.

Operators are often interested in detecting hydrogen sulfide for

personnel safety or to initiate treatment to prevent deterioration

of drilling equipment. Hydrogen sulfide in drilling mud has an

erratic and detrimental effect on the continuous gas detector. H2S

is easy to detect, however, and can be removed from the gas sample to

prevent adverse effects without influencing hydrocarbon detection. A

preset alarm indicator on the continuous H2S detector announces the

presence of potentially dangerous concentrations. A quantitative

determination of H2S in the air from any sample point may also be

made for personnel safety and recorded on the driller's console and

on the log. Operators are often interested in detecting hydrogen sulfide for

personnel safety or to initiate treatment to prevent deterioration

of drilling equipment. Hydrogen sulfide in drilling mud has an

erratic and detrimental effect on the continuous gas detector. H2S

is easy to detect, however, and can be removed from the gas sample to

prevent adverse effects without influencing hydrocarbon detection. A

preset alarm indicator on the continuous H2S detector announces the

presence of potentially dangerous concentrations. A quantitative

determination of H2S in the air from any sample point may also be

made for personnel safety and recorded on the driller's console and

on the log.

Non-combustibles gases, such as helium, carbon dioxide and nitrogen,

can be detected. Carbon dioxide may be detected in conjunction with

logging for hydrocarbons on the continuous gas detector. By applying

the steam still reflux unit and gas chromatography techniques,

quantitative analyses for other non-combustible gases can be made.

MUD LOG EXAMPLES

MUD LOG EXAMPLES

Mud log from early 1980's.

|

Generally

speaking, extremely dry gas should give mostly C1 and not much C2, C3, or C4.

If ratios are presented on the log, each of C1/C2, C2/C3, C1/C4, and

C1/C5 will be greater than 50. Wetter gas will have ratios between

20 and 50. Oil zones will have ratios between 2 and 20. Local

knowledge should be used to refine these cutoffs.

Generally

speaking, extremely dry gas should give mostly C1 and not much C2, C3, or C4.

If ratios are presented on the log, each of C1/C2, C2/C3, C1/C4, and

C1/C5 will be greater than 50. Wetter gas will have ratios between

20 and 50. Oil zones will have ratios between 2 and 20. Local

knowledge should be used to refine these cutoffs.

Operators are often interested in detecting hydrogen sulfide for

personnel safety or to initiate treatment to prevent deterioration

of drilling equipment. Hydrogen sulfide in drilling mud has an

erratic and detrimental effect on the continuous gas detector. H2S

is easy to detect, however, and can be removed from the gas sample to

prevent adverse effects without influencing hydrocarbon detection. A

preset alarm indicator on the continuous H2S detector announces the

presence of potentially dangerous concentrations. A quantitative

determination of H2S in the air from any sample point may also be

made for personnel safety and recorded on the driller's console and

on the log.

Operators are often interested in detecting hydrogen sulfide for

personnel safety or to initiate treatment to prevent deterioration

of drilling equipment. Hydrogen sulfide in drilling mud has an

erratic and detrimental effect on the continuous gas detector. H2S

is easy to detect, however, and can be removed from the gas sample to

prevent adverse effects without influencing hydrocarbon detection. A

preset alarm indicator on the continuous H2S detector announces the

presence of potentially dangerous concentrations. A quantitative

determination of H2S in the air from any sample point may also be

made for personnel safety and recorded on the driller's console and

on the log.