The real-time Measurement-While-Drilling (MWD)

screen showing a display of the pressure pulses sent

from the tools downhole (upper left), the data

transmission being decoded (lower left), as well as

a display of the drilling depth information (lower

right), and a display of the various parameters

(upper right).

The primary use of real-time surveys is in

directional drilling. For the directional driller to

steer the well towards a target zone, he must know

where the well is going, and what the effects of his

steering efforts are.

MWD tools can also provide information about the

conditions at the drill bit. This may include:

Rate of penetration

Rotational speed of the drill string

Smoothness of that rotation

Type and severity of any vibration downhole

Downhole temperature

Torque and weight on bit, measured near the drill bit

Mud flow volume

Use of this information can allow the operator to

drill the well more efficiently, and to ensure that

the MWD tool and any other downhole tools, such as

mud motors, rotary steerable systems, and LWD tools,

are operated within their technical specifications

to prevent tool failure.

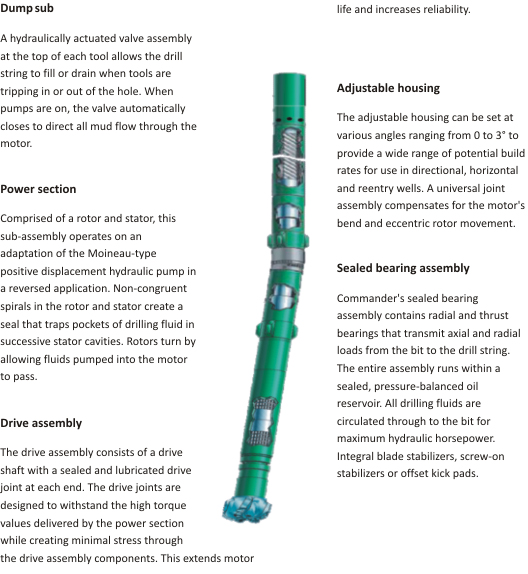

A typical MWD tool

string with steerable drilling motor.

MWD / LWD TELEMETRY SYSTEMS

MWD / LWD TELEMETRY SYSTEMS

Mud pulse

telemetry is the most common method of data

transmission used by MWD tools. Downhole, a valve is

operated to restrict the flow of the drilling mud

according to the digital information to be

transmitted. This creates pressure fluctuations

representing the information. On surface, the

received pressure signals are processed by computers

to reconstructs the transmitted information. The

technology is available in three varieties -

positive pulse, negative pulse, and continuous wave.

Positive pulse tools briefly close and open the

valve to restrict the mud flow within the drill

pipe. This produces an increase in pressure that can

be seen at surface. Negative pulse tools briefly

open and close the valve to release mud from inside

the drill pipe out to the annulus. This produces a

decrease in pressure that can be seen at surface.

Continuous wave tools gradually close and open the

valve to generate sinusoidal pressure fluctuations

within the drilling fluid. Any digital modulation

scheme with a continuous phase can be used to impose

the information on a carrier signal. The most widely

used modulation scheme is continuous phase

modulation.

When under-balanced drilling is used, mud pulse

telemetry is unusable because a compressible gas is

injected into the mud. This causes high signal

attenuation which drastically reduces the ability of

the mud to transmit pulsed data. In this case, it is

necessary to use electromagnetic waves propagating

through the formation or wired drill pipe telemetry.

Current

mud pulse telemetry technology offers a bandwidths

of up to 40 bits per second. The data rate drops

with increasing length of the wellbore and is

typically as low as 1.5 bps at a depth of 35,000 ft.

Data compression is used to increase the effective

data rate.

Current

mud pulse telemetry technology offers a bandwidths

of up to 40 bits per second. The data rate drops

with increasing length of the wellbore and is

typically as low as 1.5 bps at a depth of 35,000 ft.

Data compression is used to increase the effective

data rate.

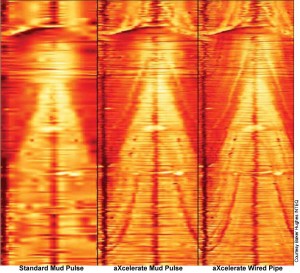

Borehole image log at

three different data

rates: standard mud pulse, accelerated mud

pulse, and wired pipe (left to right)

Electromagnetic telemetry incorporate an electrical

insulator in the drill string. To transmit data the

tool generates an altered voltage difference between

the top part (the main drill string, above the

insulator), and the bottom part (the drill bit, and

other tools located below the insulator). On surface

a wire is attached to the wellhead, which makes

contact with the drill pipe. A second wire is

attached to a rod driven into the ground some

distance away. The wellhead and the ground rod form

the two electrodes of a dipole antenna. The voltage

difference between the two electrodes is the

received signal that is decoded by a computer.

This system generally offers data rates of up to 10

bits per second. In addition, many of these tools

are also capable of receiving data from the surface

in the same way, while mud pulse-based tools rely on

changes in the drilling parameters, such as rotation

speed of the drill string or the mud flow rate, to

send information from the surface to downhole tools.

Making changes to the drilling parameters in order

to send information to the tools generally

interrupts the drilling process, causing lost time.

Wired drill pipe systems use electrical wires built

into every component of the drill string, which

carry electrical signals directly to the surface.

These systems promise data transmission rates orders

of magnitude greater then anything possible with mud

pulse or electromagnetic telemetry, both from the

downhole tool to the surface, and from the surface

to the downhole tool, at data rates upwards of 1

megabit per second,

Retrievable tools, sometimes known as slim tools,

can be retrieved and replaced using wireline through

the drill string. This generally allows the tool to

be replaced much faster in case of failure, and it

allows the tool to be recovered if the drill string

becomes stuck. Retrievable tools must be much

smaller, usually about 2 inches or less in diameter,

though their length may be 20 feet or more. The

small size is necessary for the tool to fit through

the drill string, however, it also limits the tool's

capabilities. For example, slim tools are not

capable of sending data at the same rates as collar

mounted tools, and they are also more limited in

their ability to communicate with and supply

electrical power to other LWD tools.

Collar-mounted tools, also known as fat tools,

cannot generally be removed from their drill collar

at the well site. If the tool fails, the entire

drill string must be pulled out of the hole to

replace it. However, without the need to fit through

the drill string, the tool can be larger and more

capable.

GEOSTEERING WITH MWD DATA

GEOSTEERING WITH MWD DATA

In the process of drilling a borehole, geosteering

is the act of adjusting the borehole trajectory

(inclination and azimuth angles) as the well is

being drilled, so as to reach one or more geological

targets. These changes are based on geological and

position gathered from measurement while drilling

(MWD) techniques.

Models of underground

geological structures are made from available

geological data to plan a well trajectory. A well

plan is a continuous succession of straight and

curved lines representing the geometrical figure of

the expected well path. A well plan is projected on

vertical and horizontal maps.

While the borehole is being drilled according to the

well plan, new geological information is gathered

from MWD or LWD measurements. These usually show

some differences from what was expected from the

model. As the model is continuously updated with the

new geological information and the borehole

position, changes in the trajectory can be initiated

to reach the corrected geological targets.

Geosteering and reservoir description (reservoir

modeling) are intimately linked. There is no point

steering a wellbore if you don't know where to go.

The following examples are taken from a recent

technical presentation "Horizontal Well

Geo-Navigation: Planning, Monitoring and

Geosteering" by Rocky Mottahedeh, P.Eng. P.Geol.

This paper was presented at the Petroleum Society’s

6th Canadian International Petroleum Conference

(56th Annual Technical Meeting), Calgary, Alberta,

Canada, June 7 – 9, 2005. .

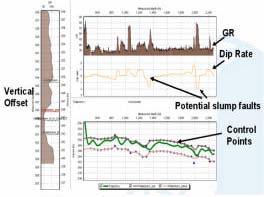

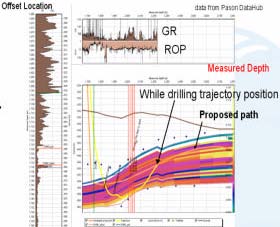

Well trajectory superimposed on a geostatistical

model of the reservoir (left) and MWD GR log and

well path (right) with FR log of vertical offset

well

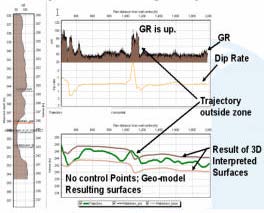

Illustration of steering back into sand after

entering shale (left) and actual versus proposed

trajectory imposed on reservoir model, GR and ROP

help confirm best sand quality (right).