|

LOGGING

WHILE DRILLING BASICS LOGGING

WHILE DRILLING BASICS

Logging while

drilling (LWD) is a technique of conveying well logging tools

downhole as part of the bottom hole assembly (BHA) while the well is

being drilled. LWD tools

transmit partial or complete measurement results to the surface via

a drilling mud-pulser or other improved techniques (Real Time Data).

Complete measurement results can be downloaded from LWD tools after

they are pulled out of the hole (Memory Data Logging). Sometimes all or

portions of the wellbore are logged or re-logged while pulling out

of the hole. This is referred to as logging while tripping.

The

first patent for an LWD tool appeared in 1932, for a tool that was a

mimic of an ES log. Developed by J. C. Karcher , President opf

Geophysical Services Inc (GSI) at the time, it used an insulated rod

inside each drill pipe secion to conduct power and transmit the

resistivity measurement to the surface. The electrodes were on an

insulated mandrill above the but. It was not very reliable and not

widely used. The

first patent for an LWD tool appeared in 1932, for a tool that was a

mimic of an ES log. Developed by J. C. Karcher , President opf

Geophysical Services Inc (GSI) at the time, it used an insulated rod

inside each drill pipe secion to conduct power and transmit the

resistivity measurement to the surface. The electrodes were on an

insulated mandrill above the but. It was not very reliable and not

widely used.

One of Karcher's LWD resistivity logs, circa 1930 One of Karcher's LWD resistivity logs, circa 1930

Many other attempts

during the 1930's through the 1960's demonstrated potential, but

were not commercially successful. Measurement While Deilling (Mud

Logging), discussed elsewhere in this Handbook, became possible in

the 1950's and gained widespread use in the 1960's onward.

Real commercial tools

arrived in the 1970's, mostly for geosteering applications. In the

1980's, more variety of measurements, including GR, resistivity, and

neutron became available. By the 1990's nearly every measurement

that could bne made by wireline in open hple, could now be made

while drilling.

Aside from the real time measurements,

LWD offers another significant advantage - there is very little

drilling fluid invasion at the time of logging, so logs are less

affected by this problem. Borehole conditions may also be better

than is the case for wireline logging.

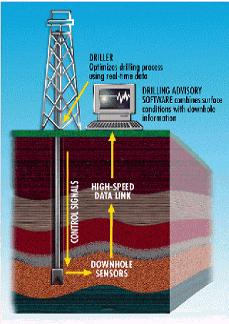

The LWD concept

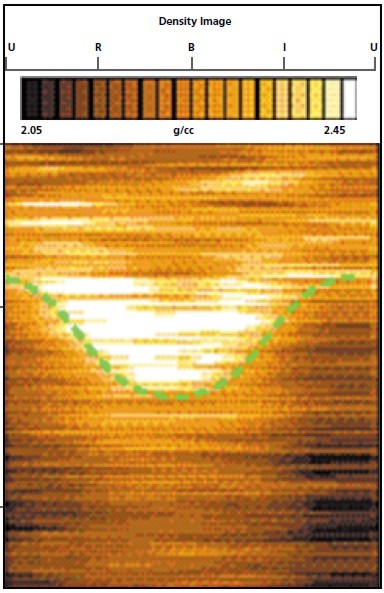

LWD density image log (not available as a wireline log), black is

low density (shale or porous), LWD density image log (not available as a wireline log), black is

low density (shale or porous),

white is high density (tight).

Measurement While Drilling (MWD) Is a term used to

describe drilling related measurements made at the

surface or made downhole and transmitted to the

surface while drilling a well. The terms MWD and LWD

are sometimes used interchangeably, but we like to

think of LWD as the process of obtaining information

about the rocks (porosity, resistivity, etc) and MWD

as obtaining information about the progress of the

drilling operation (rate of penetration, weight on

bit, wellbore trajectory, etc). MWD today often

refers to geosteering measurements made to help

decide on changes to the wellbore path.

The measured

results are stored in LWD and MWD tools and some of

the results can be transmitted digitally to surface

using mud-pulse telemetry. Certain

MWD systems have the capability of receiving encoded

control commands which are sent by turning on and

off mud pumps and/or changing the rotation speed of

the drill pipe. These messages allow the drill bit to be

steered in a desired direction

LWD technology was

developed originally as an enhancement to the earlier MWD technology to completely or partially replace

wireline logging operation. With the improvement of the technology

in the past decades, LWD is now widely used for drilling (including

geosteering), formation evaluation, especially for high angle wells.

In frontier areas, deep water offshore, and critical wells anywhere,

the real time log data as the well is drilled may be critical to the

success and economics of the well.

LOGGING WHILE DRILLING TOOL STRING (BOTTOM HOLE ASSEMVLY - BHA) LOGGING WHILE DRILLING TOOL STRING (BOTTOM HOLE ASSEMVLY - BHA)

Schematic drawing of a typical LWD tool string with multiple

sensors.

Over the years, a

majority of the conventional wireline measurements have been made

available in LWD. Certain new measurements are available only in LWD,

for example density imaging logs. The following is a

list of available measurement in LWD:

Natural gamma ray

Spectral gamma ray

Azimuthal gamma ray

Gamma ray close to drill bit.

Density and photoelectric index

Neutron porosity

Borehole caliper

Ultra sonic azimuthal caliper

Density caliper

Attenuation and phase shift resistivities at different transmitter

spacings

and frequencies

Resistivity at the drill bit

Deep directional resistivities

Compressional slowness

Shear slowness

Density borehole images

Resistivity borehole images

Formation tester and sampler

Formation pressure

Nuclear magnetic resonance

Seismic while drilling

Vertical seismic profile

LOGGING WHILE DRILLING EXAMPLES LOGGING WHILE DRILLING EXAMPLES

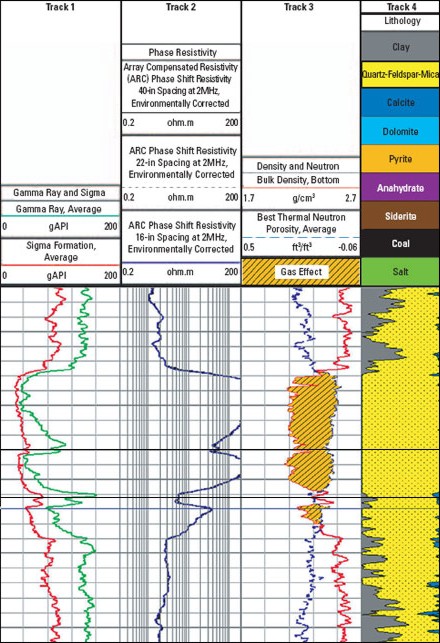

Resistivity, density, neutron, gamma ray, and capture cross

section (sigma) recorded while drilling. The sigma curve (scaled

in GR units in Track 1) shows the lower part of the sand to be

clean, even though the GR is somewhat radioactive (confirmed by

constant density neutron crossover). Gas crossover

is more obvious on LWD logs as there is little flushing of

moveable hydrocarbons due to limited time for drilling fluid

invasion. If the LWD is run while tripping or on a wiper

trip, invasion can be deeper, and may vary from one run to

another.

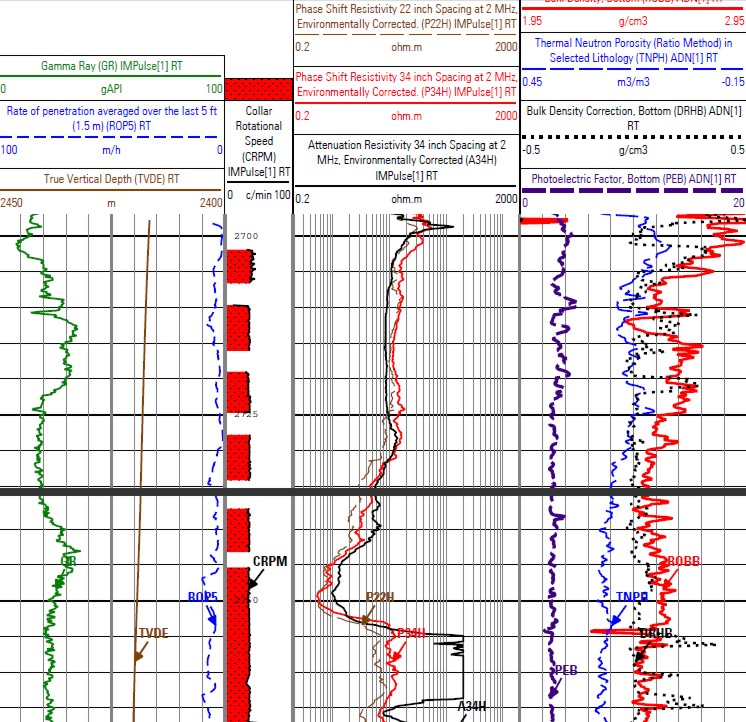

LWD log in horizontal well. GR and true vertical depth

(TVDE) in Track 1, resistivity in Track 2, porosity and PE

curves in Track 3. The low resistivity below the heavy

black line on the log indicates that the well dropped below the

oil water contact (TVD > 2418 +/-). Much of the horizontal leg

beyond this point is in or near the water.

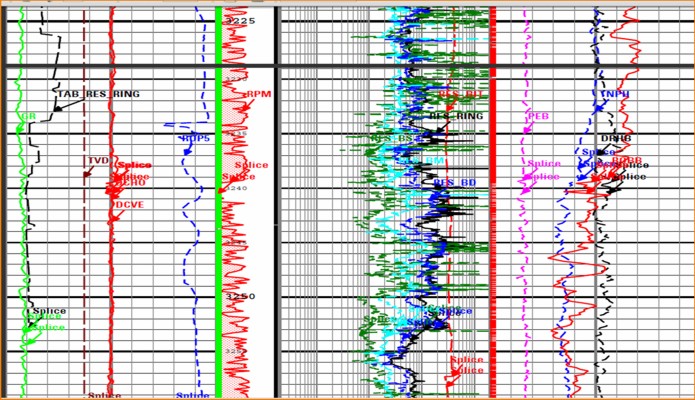

This LWD example shows GR, TVD, and caliper in Track 1, with drilling

characteristics such as rate of penetration, torque at the bit,

and bit RPM. Track 2 gives shallow, medium, and deep resistivity

- separation between the curves and spikes to the left indicate

fractures in an oil reservoir. PE, density and neutron curves

are in Track 3. These logs were run in short "wiper trip" segments and

spliced in the computer - each curve is spliced at a different

depth because of their position in the tool string. Some curves

may not splice perfectly due to changes in the invasion profile

over time.

|