|

COILED TUBING (CT) LOGGING BASICS

COILED TUBING (CT) LOGGING BASICS

Coiled tubing (CT) refers to metal piping, normally 1" to 3.25" in

diameter that comes spooled on a large reel. It is used to carry out

operations similar to those run on wireline, as well as drilling,

fracturing, and acidizing operations. The main benefits over

wireline are the ability to pump chemicals through the tubing and

the ability to push the tubing into the hole rather than

relying on gravity. This is especially useful in highly deviated or

horizontal wells. However, for offshore operations, the footprint for

a coiled tubing operation is generally larger than for wireline.

A

CT operation can be performed through the drilling derrick or from a

self contained unit and a derrick truck. On offshore platforms with

no drilling facilities, a self supporting tower can be used instead.

On some offshore wells, a semi-submersible has to be utilized to

support all the surface equipment and personnel, whereas wireline

can be carried out from a smaller and cheaper vessel.

The tool string at the bottom of

the tubing is called the bottom hole assembly (BHA). It can range

from something as simple as a jetting nozzle, for jobs involving

pumping chemicals or cement, to a larger string of logging and

steering tools. CT conveyed logging can use wireline inside the

tubing or memory tools that record the measurements that are then

played back when the tool is retrieved.

A coiled tubing operation

in progress

Before the invention of coiled

tubing rigs, logging tools were sometimes delivered to the bottom of

the hole on the end of drill pipe. The logging tool has to be fitted

to the bottom of the drill pipe, and the logging cable run through

the drill pipe, a very tedious and time consuming process. Logging

tools were often damaged on the way in, as running pipe is a

relatively rough process. Logs were recorded while running into the

hole, just in case, then also logged on the way out. This process is

still done in some parts of the world where coiled tubing rigs are

not yet common.

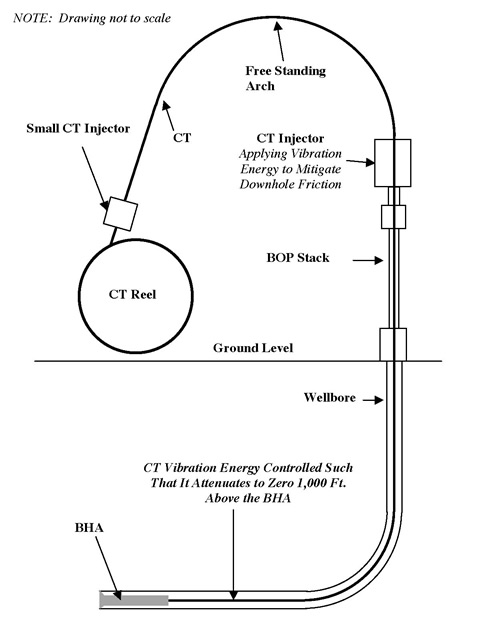

Schematic diagram of a coiled tubing

job into a horizontal well. The Bottom Hole Assembly can be a

logging tool suite, a drilling and steering assembly, or a hydraulic

fracture stimulation setup.

|