|

ELASTIC CONSTANTS BASICS

ELASTIC CONSTANTS BASICS

Well logs are often used to determine the

mechanical properties of rocks. These properties are often called

the elastic properties or elastic constants of rocks. The subject

matter and practice of calculating these rock properties is often

called "rock physics".

The best known

elastic constants are the bulk modulus of compressibility, shear

modulus, Young's

Modulus (elastic modulus), and Poisson's Ratio. The dynamic elastic

constants can be derived with appropriate equations, using sonic log

compressional and shear travel time along with density log data.

Elastic constants

are needed by five distinct disciplines in the petroleum industry:

1. geophysicists interested in using logs to improve

synthetic seismograms, seismic models, and interpretation of seismic

attributes, seismic inversion, and processed seismic sections.

2. production or completion engineers who want to determine

if sanding or fines migration might be possible, requiring special

completion operations, such as gravel packs

3. hydraulic fracture design engineers, who need to know

rock strength and pressure environments to optimize fracture

treatments

4. geologists and engineers interested in in-situ stress

regimes in naturally fractured reservoirs

5. drilling engineers who wish to prevent accidentally

fracturing a reservoir with too high a mud weight, or who wish to

predict overpressured formations to reduce the risk of a blowout.

Mechanical properties are used to

design hydraulic fracture stimulation programs in oil and gas wells,

and in the design of mines and gas storage caverns. In this

situation, the mechanical properties are derived in the laboratory

or from well log analysis, calibrated to the lab results.

In seismic petrophysics, these same mechanical properties are called

seismic attributes. They are derived by inversion of time-domain

seismic data, calibrated to results from well log analysis, which in

turn were calibrated to the lab data. The vertical resolution of

seismic data is far less than that of well logs, so some filtering

and up-scaling issues have to be addressed to make the comparisons

meaningful.

The main purpose for finding these

attributes is to distinguish reservoir quality rock from

non-reservoir. The ultimate goal is to determine porosity,

lithology, and fluid type by "reverse-engineering" the seismic

attributes. The process is sometimes called "quantitative seismic

interpretation". In high porosity areas such as the tar sands, and

in high contrast areas such as gas filled carbonates,, modest

success has been achieved, usually after several iterative

calibrations to log and lab data. Something can be determined in

almost all reservoirs, but how "quantitative" it is may not be

known.

There are many other types of

seismic attributes related to the signal frequency, amplitude, and

phase, as well as spatial attributes that infer geological structure

and stratigraphy, such as dip angle, dip azimuth, continuity,

thickness, and a hundred other factors. While logs may be used to

calibrate or interpret some of these attributes, they are not

discussed further here.

ELASTIC CONSTANTS DEFINITIONS

ELASTIC CONSTANTS DEFINITIONS

The elastic constants of rocks are defined by the

Wood-Biot-Gassmann Equations. The

equations can be transformed to derive

rock properties from log data. If

crossed dipole sonic data is available, anisotropic stress can

be noticed by differences in the X and Y axis displays of both

the compressional and shear travel times. When this occurs, all

the elastic constants can be computed for both the minimum and

maximum stress directions. This requires the original log to be

correctly oriented with directional information, and may require

extra processing in the service company computer center.

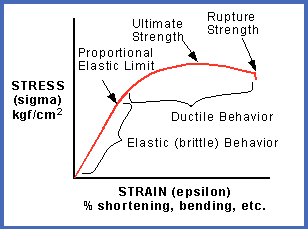

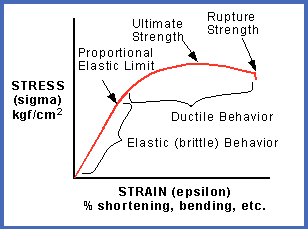

Elasticity is a property of matter,

which causes it to resist deformation in volume or shape.

Hooke's Law, describing the behavior of elastic materials,

states that within elastic limits, the resulting strain is

proportional to the applied stress. Stress is the external

force applied per unit area (pressure), and strain is the fractional

distortion which results because of the acting force.

The modulus

of elasticity is the ratio of stress to strain: The modulus

of elasticity is the ratio of stress to strain:

0: M = Pressure / Change in Length = {F/A}

/ (dL/L)

This is identical to the definition of Young's Modulus. Both

names are used in the literature so terminology can be a bit

confusing.

Different types of deformation can result,

depending upon the mode of the acting force. The three elastic moduli are:

Young's Modulus

Y (also abbreviated E in various literature),

1: Y = (F/A) / (dL/L)

Bulk Modulus

Kc,

2: Kc = (F/A) / (dV/V)

Shear Modulus

N, (also abbreviated as u (mu))

3: N = (F/A) / (dX/L) = (F/A) / tanX

Where:

F/A = force per unit area

dL/L, dV/V, dX/L = fractional strains of length,

volume, and shape, respectively.

Note: dX/L can be represented by tanX.

Poisson's Ratio

PR (also abbreviated v (nu)), is defined

as the ratio of strain in a perpendicular direction to the

strain in the direction of extensional force, Poisson's Ratio

PR (also abbreviated v (nu)), is defined

as the ratio of strain in a perpendicular direction to the

strain in the direction of extensional force,

4: PR = (dX/X) / (dY/Y)

Where:

X and Y = original dimensions

dX and

dY = changes in X and Y directions respectively, as

the

deforming stress acts in Y direction.

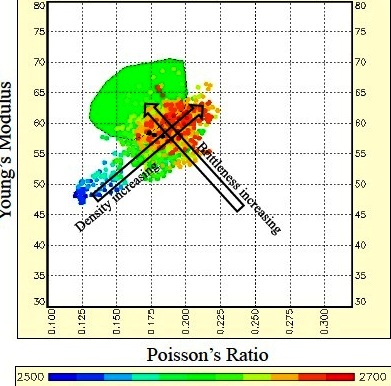

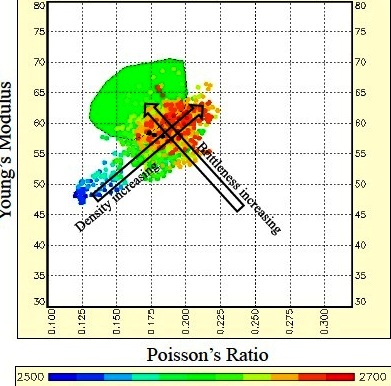

Young's Modulus vs Poison's Ratio: Brittleness increases

toward top left, density increases toward top right, porosity plus

organic content and depth decrease toward bottom left. PR values

less than 0.17 indicate gas or organic content or both. (image

courtesy Canadian Discovery Ltd)

All of these

moduli can be derived directly from well logs and indirectly from

seismic attributes:

5: N = KS5 * DENS / (DTS ^ 2)

6: R = DTS / DTC

7: PR = (0.5 * R^2 - 1) / (R^2 - 1)

8: Kb = KS5 * DENS * (1 / (DTC^2) - 4/3 * (1 / (DTS^2)))

9: Y = 2 * N * (1 + PR)

Lame's Constant Lambda, (also abbreviated

λ) is a

measure of a rocks brittleness, which is a function of both Young's

Modulus and Poisson's Ratio:

10:

Lambda = Y * PR / ((1 + PR) * (1 - 2 * PR))

OR 10A: Lambda = DENS * (Vp^2 - 2 * Vs ^ 2)

Some people prefer different abbreviations: Mu or u

for shear modulus, Nu or

v

for Poisson's Ratio, and E for Young's Modulus. The abbreviations

used above are used consistently trough these training materials.

In the seismic industry, it is common to think in terms of

velocity and acoustic impedance in addition to the more classical

mechanical properties described above.

The compressional to shear velocity ratio is a good

lithology indicator:

11. R = Vp / Vs = DTS / DTC

Acoustic impedance:

12: Zp = DENS / DTC

13: Zs = DENS / DTS

Where:

DTC = compressional sonic travel time

DTS = shear sonic travel time

DENS = bulk density

KS5 = 1000 for metric units

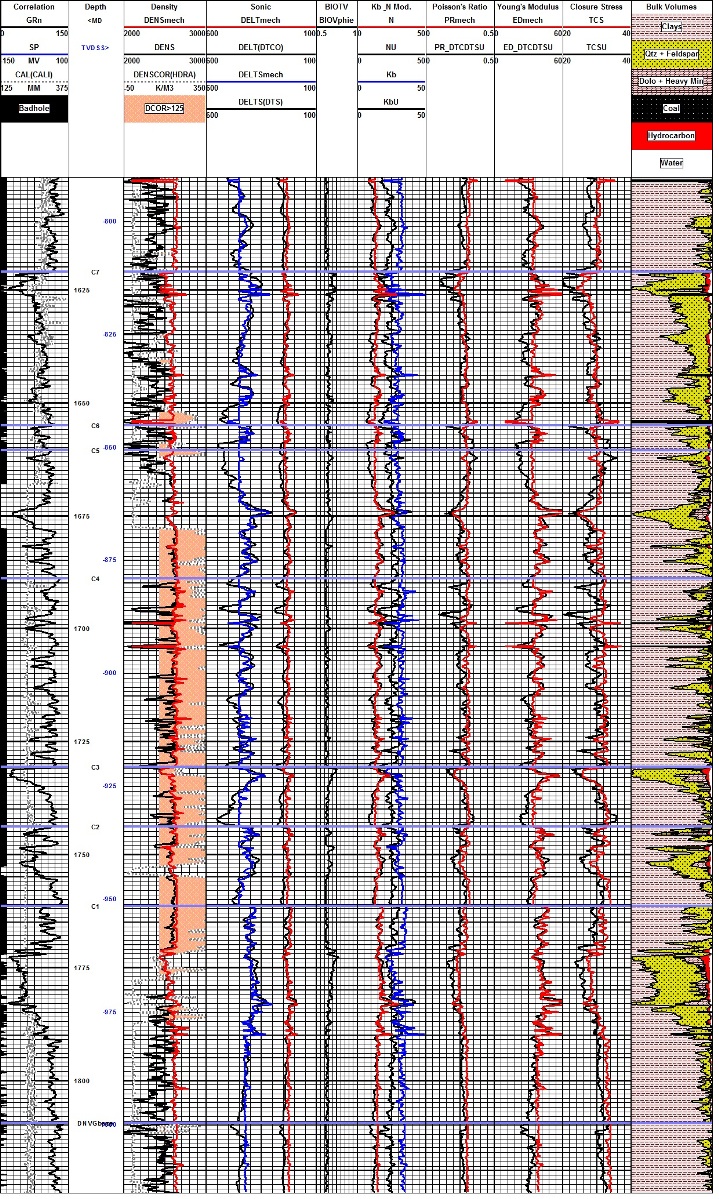

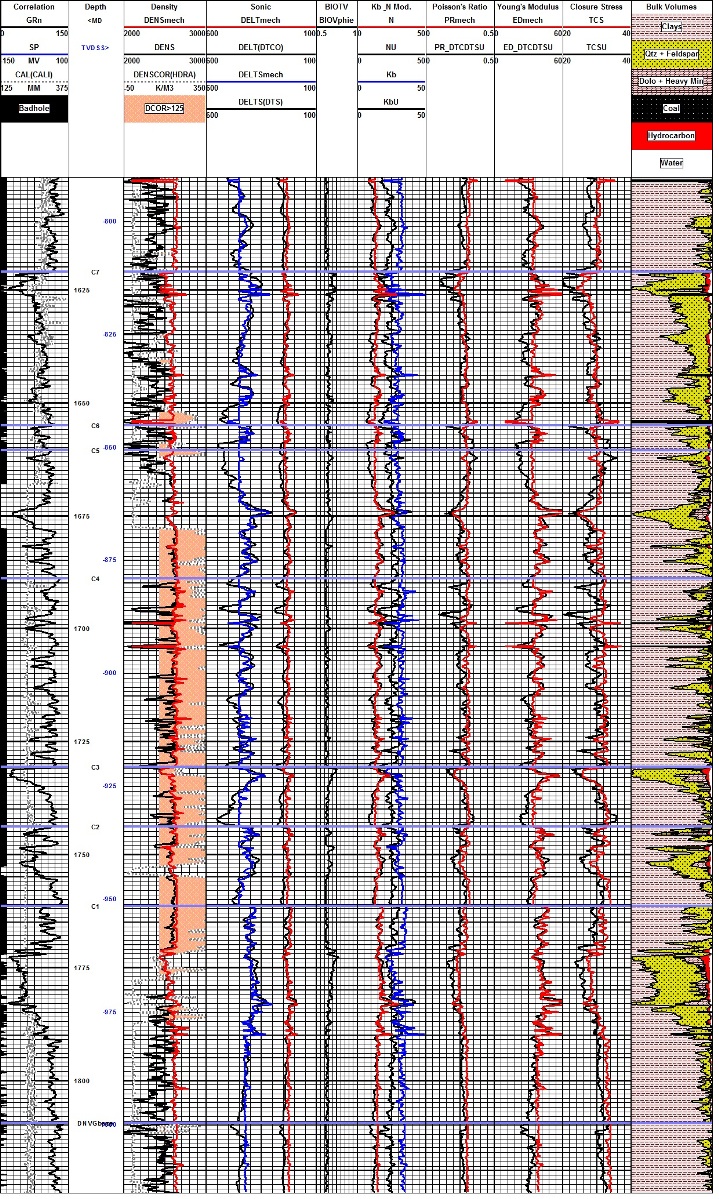

An example of a log analysis for mechanical rock properties

(elastic constants) is shown below. Coloured dots represent lab

derived data, and illustrate the close match obtained betwee log

analysis and lab measured data.

Dynamic elastic properties calculated from density and sonic log

data, showing close match to dynamic data from lab measurements

(coloured dots). Lab data is from table shown above. Note synthetic

sonic and density plotted next to measured log curves (Tracks 2 and

3), showing reasonably small differences due to minor borehole

effects. Synthetic curves can repair worse logs or even replace

missing curves.

ELASTIC CONSTANTS CROSSPLOTS

ELASTIC CONSTANTS CROSSPLOTS

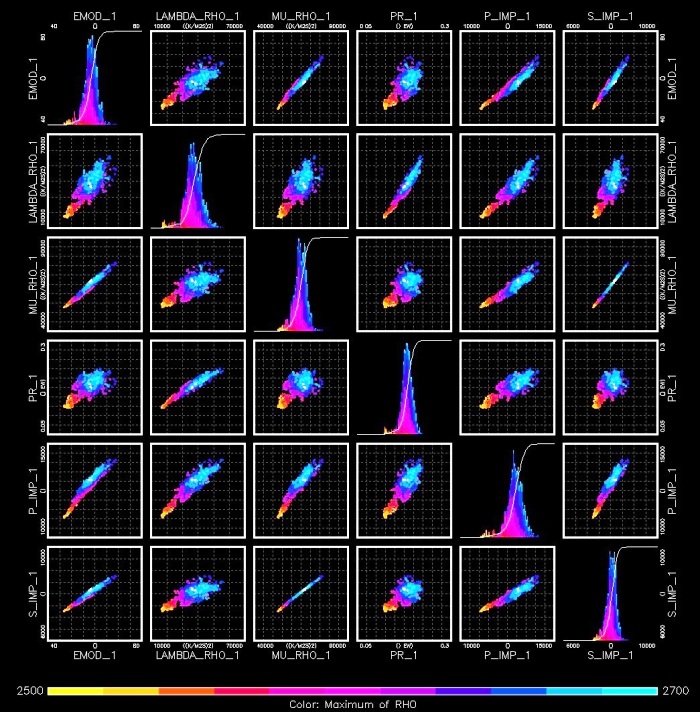

Composite seismic attributes, such as Lame's Constant times

density (Lambda_Rho) and shear modulus times density (Mu_Rho), are

used to normalize attributes to make interpretation easier.

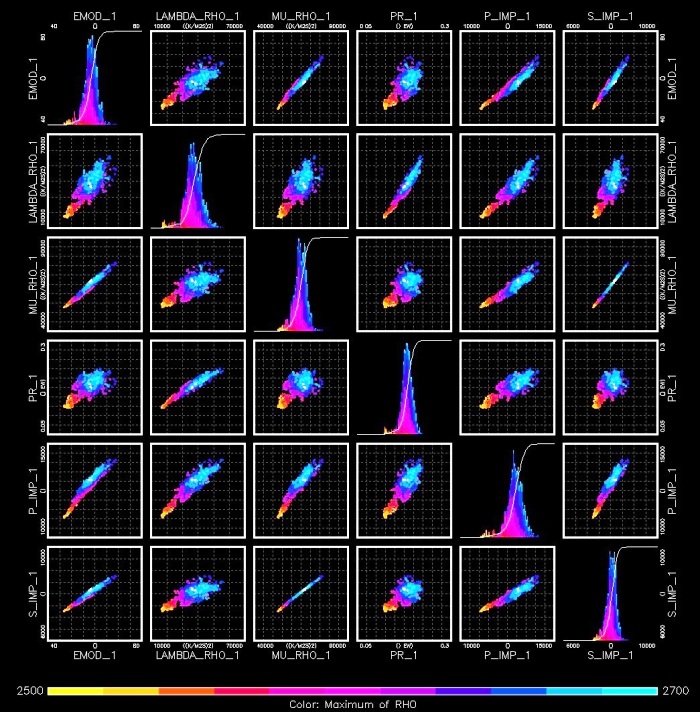

Various crossplots of results are used to

distinguish differences between rock types, as shown below. The

colour code represents depth (red-orange = shallower, blue-green =

deeper)

Crossplots of the elastic constants are used to identify variations

in rock characteristics, by noting changes in the data

distributions. (RHO = density, PR = Poisson's Ratio, MU = shear

Modulus, LAMBDA = Lame's Constant, BMOD = bulk modulus, EMOD =

Young's Modulus, P_IMP = compressional wave acoustic impedance,

S_IMP = shear wave acoustic impedance, (image courtesy Canadian

Discover Ltd)

EFFECTS OF ANISOTROPY

EFFECTS OF ANISOTROPY

The elastic constants are often considered to be uniform in the

three cardinal axes. Under this assumption, a sonic log would read

the same value in all directions. However, in a rock under

horizontal tectonic stress, there is a minimum and a maximum stress

direction, and the acoustic properties vary with that stress. Using

the crossed dipole mode of the dipole shear sonic log, we can

provide acoustic velocity (or travel time) in these two directions.

Example of a dipole shear image log run in crossed dipole

mode. It has two compressional and two shear curves measured

in orthogonal directions. An anisotropy coefficient

can be computed from the difference between the two

compressional curves - note the interval near the top f the log

where the curves separate and the image log gets "shaky",

indicating stress anisotropy. Fractures are indicated

where the high amplitude (red colour on image log) disappears.

Full wave, array, and dipole sonic log presentations

vary widely, depending on age, service company, and intended

use.

Acoustic anisotropy coefficient is defined as:

1: Kani = 0.5 * (Vmax - Vmin) / (Vmax + Vmin)

Where:

Kani = anisotropy coefficient (fractional)

Vmin = minimum acoustic (seismic) velocity (m/sec or ft/sec)

Vmax = maximum acoustic (seismic) velocity (m/sec or ft/sec)

Equation 1 can be rewritten in log analysis terms as:

2: Kani = 0.5 * (DTCmax - DTCmin) / (DTCmax +

DTCmin)

Because of tool rotation, the log curves that represents the

maximum and minimum values trade places, so the best solution is to

take the absolute value of the difference between the two sonic log

curves in the numerator. Some people multiply the anisotropy

coefficient by 100 and display it as a percentage. Typical values

range from zero for no anisotropy to as much as 25% in highly

stressed regions.

An anisotropy coefficient based on resistivity values is

also generated from well logs, but it has nothing to do with stress

assessments. In this case it refers to the differences between

vertical and horizontal resistivity in laminated rocks.:

3: AnisRatio = RESvert / REShoriz

4: AnisCoef = AnisRatio ^ 0.5

The resistivity ratio as defined here is nearly always

greater than 1.0, and some literature uses the inverse of these

terms, maintaining the same nomenclature..

LAB

MEASUREMENT PROCEDURES

LAB

MEASUREMENT PROCEDURES

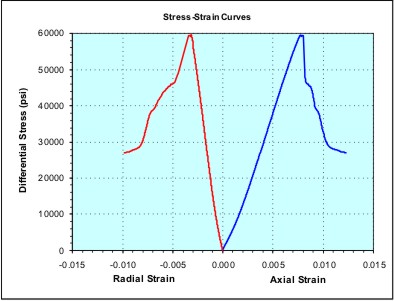

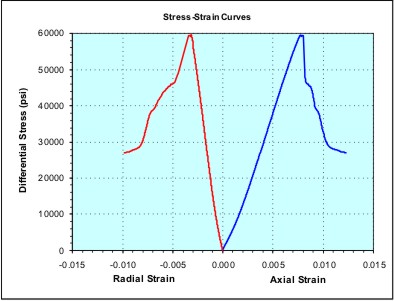

Elastic properties are measured in the laboratory using triaxial

stress tests (static measurements) and by measuring bulk density

and acoustic travel time with a high frequency impulse (dynamic

testing). Both are done under representative overburden

pressure.

The general

procedures for triaxial compressive test are:

1. A right cylindrical plug is cut from the sample core and

their ends ground parallel according to International Society for

Rock Mechanics (ISRM) and American Society for Testing and Materials

(ASTM) standards. A length to diameter ratio of 2:1 is recommended

to obtain representative mechanical properties of the sample, which

is also recommended by ASTM and ISRM. Physical dimensions and

weight of the specimen are recorded and the specimen is saturated

with simulated formation brine.

2. The specimen is then placed between two plates and a heat-shrink

jacket is placed over the specimen.

2. The specimen is then placed between two plates and a heat-shrink

jacket is placed over the specimen.

3. Axial strain and radial strain devices are mounted in the

endcaps and on the lateral surface of the specimen, respectively.

4. The specimen assembly is placed into the pressure vessel and

the pressure vessel is filled with hydraulic oil.

5. Confining pressure is increased to the desired hydrostatic testing

pressure.

6. Measure ultrasonic velocities at the hydrostatic confining

pressure.

7. Specimen assembly is brought into contact with a loading

piston that allows application of axial load.

8. Increase axial load at a constant rate until the specimen fails

or axial strain reaches a desired amount of strain while confining

pressure is held constant.

9. Reduce axial stress to the initial hydrostatic condition after

sample fails or reaches a desired axial strain.

10. Reduce confining pressure to zero and disassemble sample.

|

Depth

(m) |

Confining

Pressure (psi) |

Compressive

Strength (psi) |

Static

Young's

Modulus

(x106 psi) |

Static

Poisson's

Ratio |

|

XX51.50 |

3850 |

63359 |

8.70 |

0.40 |

|

XX61.15 |

3850 |

56831 |

5.75 |

0.36 |

|

XX71.15 |

3850 |

56026 |

5.79 |

0.34 |

|

XX05.20 |

3850 |

50910 |

5.08 |

0.39 |

Static elastic properties

measured with triaxial stress test

|

Depth |

Bulk |

Ultrasonic

Wave Velocity |

Dynamic

Elastic Parameter |

|

|

m |

Density

g/cc |

Compressional

ft/sec usec/ft |

Shear

ft/sec |

usec/ft |

Young's

Modulus (x106 psi) |

Poisson's

Ratio |

Bulk Modulus

(x106 psi) |

Shear

Modulus (x106 psi) |

|

XX51.50 |

2.81 |

20161 |

49.60 |

10760 |

92.94 |

11.39 |

0.30 |

9.53 |

4.38 |

|

XX61.15 |

2.57 |

15829 |

63.18 |

9555 |

104.66 |

7.68 |

0.21 |

4.46 |

3.16 |

|

XX71.15 |

2.66 |

17226 |

58.05 |

10299 |

97.10 |

9.30 |

0.22 |

5.57 |

3.81 |

|

XX05.20 |

2.64 |

16451 |

60.79 |

9763 |

102.43 |

8.31 |

0.23 |

5.10 |

3.38 |

Dynamic elastic properties

measured with ultrasonic impulse in the lab. Note differences

between static and dynamic values. Elastic properties from log

analysis models match lab dynamic data better than static data.

Dynamic elastic properties calculated from density and sonic log

data, showing close match to dynamic data from lab measurements

(coloured dots). Lab data is from table shown above. Note synthetic

sonic and density plotted next to measured log curves (Tracks 2 and

3), showing reasonably small differences due to minor borehole

effects. Synthetic curves can repair worse logs or even replace

missing curves.

Examples of Mechanical Properties Logs

Examples of Mechanical Properties Logs

The format and curve complement of Mechanical Properties Logs vary widely between service

companies and age of log. Some logs have Metric depths but the moduli are in English units. Some are vice versa. Here are some

examples.

Example of log reconstruction in a shaly sand sequence (Dunvegan).

The 3 tracks on the left show the measured gamma ray, caliper,

density, and compressional sonic. Original density and sonic are

shown in black, modeled logs are in colour. Shear sonic is the model

result as none was recorded in this well. Computed elastic

properties are shown in the right hand tracks. Results from the

original unedited curves are shown in black, those after log editing

are in colour. Note that the small differences in the modeled logs

compared to the original curves propagate into larger differences in

the results, especially Poisson's Ratio (PR), Young's Modulus (ED),

and total closure stress (TCS).

Mechanical properties log with lithology/porosity track at

the right. This analysis was run to find out if sanding might

occur during production from the oil zone. High bulk modulus and

low sher modulus suggest sanding is like. Stress failre (shaded

black in Track 1) shows where sanding is most likely to occur.

|

The modulus

of elasticity is the ratio of stress to strain:

The modulus

of elasticity is the ratio of stress to strain: Poisson's Ratio

PR (also abbreviated v (nu)), is defined

as the ratio of strain in a perpendicular direction to the

strain in the direction of extensional force,

Poisson's Ratio

PR (also abbreviated v (nu)), is defined

as the ratio of strain in a perpendicular direction to the

strain in the direction of extensional force,

2. The specimen is then placed between two plates and a heat-shrink

jacket is placed over the specimen.

2. The specimen is then placed between two plates and a heat-shrink

jacket is placed over the specimen.