|

Fracture Pressure BASICS

Fracture Pressure BASICS

A major use of

mechanical properties from log analysis is in the design of casing

and mud weight programs for new wells to minimize the chance for

accidental formation breakdown and loss of circulation while

drilling. The critical pressure for formation breakdown in open hole

is called the “fracture pressure”.

A second use is

in the design of hydraulic fracture treatments to improve oil or gas

well performance. The critical pressure in such a design is the

“minimum horizontal stress”. Hydraulic fractures are usually

performed through perforations in well cemented casing. The pressure

required to break a rock in this scenario is lower than in open

hole. Unfortunately, this is often called the “fracture pressure” in

much of the literature, and can easily be confused with the fracture

pressure calculated for open hole situations.

Hydraulic

fracturing is a process in which pressure is applied to a reservoir

rock on purpose in order to break or crack it. These cracks are

called hydraulic fractures. Most hydraulic and natural fractures are

near vertical and increase well productivity significantly.

Hydraulic

fracturing may use sand to prop the fracture open, so it cannot

re-seal itself due to the enormous pressure exerted by the overlying

rock. Some reservoirs have natural fractures; others need to have

fractures added by us. Some wells flow oil and gas at rates that

make fracturing unnecessary.

Fracture

optimization involves designing a fracturing operation that is

strong enough to penetrate the reservoir rock and yet weak enough

not to break into zones where it is not wanted. In addition, a cost

effective design that minimizes time and materials is needed.

The extent of a

hydraulic fracture is a complex relationship between the strength of

the rock and the pressure difference between the rock and the

fracturing pressure. The extent is defined by the fracture

dimensions - height, depth of penetration (wing length or fracture

length), and aperture (width or opening).

One measure of a

rock's strength is Poisson's Ratio. Poisson's Ratio are low (0.10 to

0.30) for most sandstones and carbonates. These rocks fracture

relatively easily. Poisson's Ratio is high (0.35 to 0.45) for shale,

very shaly sandstone, and coal. These rocks are more elastic and are

harder to fracture. Shales are often the upper and lower barrier to

the height of a fracture in conventional sandstone.

A useful

indicator of rock strength is the Fracture Toughness Modulus,

defined as:

1: FTM = ((PR / (1-PR))^2) / N

Shales have a higher FTM than most reservoir rocks.

The lateral extent

of a fracture is primarily determined by Young's Modulus. Stiffer

rocks have higher Young's Modulus and are easier to fracture.

By using

radioactive tracers in the fracturing fluid, the extent of the

fracture can be traced by a gamma ray log. Adequate fracture depth

of penetration (fracture length) is also desired, as is fracture

aperture (fracture width). These are not as easy to determine from

logs as is the fracture height. Different tracer elements are used

during the frac so that a spectral gamma ray log can be used to

determine depth of penetration.

Fracture

pressure is the pressure needed to create a fracture in a rock while

drilling in open hole. Closure stress is the pressure needed to

fracture a rock through perforations in cased hole. In some

literature, closure stress and fracture pressure are used

interchangeably or ambiguously.

Both are

determined by the overburden pressure (a function of depth and rock

density), pore pressure, Poisson's Ratio, porosity, tectonic

stresses, and anisotropy. Breakdown pressure is the sum of the

closure stress and the friction effects of the frac fluid being

delivered to the formation. Breakdown pressure can be considerably

higher than closure stress.

Closure

stress is the pressure at which the fracture closes after the

fracturing pressure is relaxed. It is usually between 80 and 90% of

breakdown pressure. Rocks with high closure stress are harder to

frac (take more horsepower) than the same rocks with lower closure

stress. Shallow shaly sands have high closure stress because they

have high Poisson's Ratio.

Mini-frac (cased hole) or leak-off test (open hole) pressure

test versus time, showing

definitions of pressure terminology

Many

technical papers and computer programs use pressure gradients

instead of pressures to define the calculations. Typical pressure

gradient values are:

Pore

pressure - normal pressure regime

KP1 = 0.433 to 0.460 psi/foot for English units

KP1 = 9.81 to 10.4 KPa/meter for Metric units

Pore

pressure - abnormal pressure regime

KP1 = 0.460 to 1.00 psi/foot for English units

KP1 = 10.4 to 22.6 KPa/meter for Metric units

Overburden

pressure

KP1 = 0.91 to 1.26 psi/foot for English units

KP1 = 20.6 to 28.5 KPa/meter for Metric units

Closure

stress - typical range

KP1 = 0.63 to 0.88 psi/foot for English units

KP1 = 12.0 to 20.0 KPa/meter for Metric units

The

average closure stress in the undisturbed part of the Western

Canadian basin is 16.5 KPa/meter.

Stress regime - no tectonic stress (left), tectonic stress (right)

CALCULATING

CLOSURE and FRACTURE

STRESS CALCULATING

CLOSURE and FRACTURE

STRESS

CASE

1: Isotropic Reservoir (Basic Model)

CASE

1: Isotropic Reservoir (Basic Model)

The stress equations are:

1: KPR1

= PR / (1 – PR)

2: Px = Py = KPR1 * Po + (1 – KPR1) * Pp * ALPHA

3: Pclos = Py

4: Pfrac = 2 * Px

NUMERICAL EXAMPLE:

1.

Typical overpressure case:

Assume PR = 0.20 so KPR1 = 0.25

Assume Po = 1000 psi, Pp = 8000 psi

Assume Porosity = 0.20 so ALPHA = 0.62 + 0.935 * Porosity = 0.80

Pclos = 0.25 * 10000 + .0.75 * 8000 * 0.80

= 2500 + 6000 * 0.80

= 2500 + 4800 = 7300 psi

So closure stress in this example is less than pore pressure. If

porosity were higher, Biot’s constant ALPHA would be closer to 1.0

and closure stress would be greater than pore pressure.

2.

For a tyouxak normal pressure case:

Assume Pp = 4500 instead of 8000 psi

Pclos = 0.25 * 10000 + .0.75 * 4500 * 0.80

= 2500 + 3400 * 0.80

= 2500 + 2700 = 5200 psi

So closure stress is more than pore pressure.

If PR = 0.20 and porosity = 0.00, then ALPHA = 0.00, Pp = 0.0, and

Pclos = 2500, a very counter intuitive result.

Values have been rounded for demonstrarion purposes.

To initiate a frac, you only need to exceed closure stress.

CASE

2: Anisotropic Reservoir (Standard Model)

CASE

2: Anisotropic Reservoir (Standard Model)

The stress equations are:

1:

KPR1 = PR / (1 – PR)

2: Px = KPR1 * Po + (1 – KPR1) * Pp * ALPHA + Pext

3: Py = KPR1 * Po + (1 – KPR1) * Pp * ALPHA

4: Pclos = Py

5: Pfrac = 3 *

Px – Py + Ts

CASE

3: Anisotropic Reservoir (Iverson Model)

CASE

3: Anisotropic Reservoir (Iverson Model)

The stress equations are:

0: KPR1 = (PRyz * PRxy + PRxz) / (1 - PRxy * PRyx)

Assume PRxy = PRxz = PRmax

And PRyx = PRyz = PRmin

Then 1: KPR1

= (PRmin * PRmax + PRmax) / (1 - PRmax * PRmin)

2: Pclos = KPR1 * Po + (1 – KPR1) * Pp * ALPHA + Pext

CASE

4: Anisotropic Fractured Reservoir (Iverson Model)

CASE

4: Anisotropic Fractured Reservoir (Iverson Model)

The stress equations are:

0: KPR1 = (PRy^2 + PRx) / (1 - PRy^2)

Assume PRy = PRmax

And PRx = PRmin

Then 1: KPR1

= (PRmin * PRmax + PRmax) / (1 - PRmax * PRmin)

2: Pclos = KPR1 * Po + (1 – KPR1) * Pp * ALPHA + Pext

CASE

5: Total Stress Equation (Barree Model)

CASE

5: Total Stress Equation (Barree Model)

1:

KPR1 = PR / (1 – PR)

2: Pclos = KPR1 * (Po - ALPHAv * (Pp + Poff)) + ALPHAh

* (Pp + Poff) + Y * STh + Pext

The

usual assumption is that ALPHAv = ALPHA and ALPHAh = 1.00. Poff

accounts for pressure decline in the reservoir due to depletion

from offset wells. STRh and Pext are still assumptions and are

found by calibration to mini-fracs.

Where:

Px = stress in the maximum stress direction (psi or KPa)

Py = stress in the minimum stress direction (psi or KPa)

Po = overburden pressure (psi or KPa)

Pp = formation (pore) pressure (psi or KPa)

PR = Poisson’s ratio (fractional)

PRmax = Poisson’s ratio calculated with minimum DTS (fractional)

PRmin = Poisson’s ratio calculated with maximum DTS (fractional)

ALPHA = Biot’s elastic constant (fractional)

ALPHAh = horizontal Biot’s elastic constant (fractional)

ALPHAv = vertical Biot’s elastic constant (fractional)

Pext = unbalanced tectonic stress (psi or KPa)

STRt = tensile strength (psi or KPa)

Pclos =

formation closure stress in cased hole (psi or KPa)

Pfrac = formation fracture pressure (psi or KPa)

(Pf/D) = fracture pressure gradient (psi/ft or KPa/meter)

Y = Young's Modulus (psi)

STRh = regional horizontal strain (microstrains)

Poff = Pore pressure offset (psi)

When

formation stress is isotropic (equal in all directions),

the tectonic stress (Pext) is zero and Px equals Py.

Some previous authors have ignored Biot’s Constant

ALPHA in their equations. Since ALPHA = 1.0 only rarely,

leaving ALPHA out of the equation is not a good idea for

real rocks when the zone is porous. Tensile strength (Ts)

of most rocks is low or zero so the term is usually ignored.

In all the above cases, the fracture pressure for a zero

porosity case can be calculated by setting ALPHA = 0 and

PR = PRo. When ALPHA = 0, there is no contribution from Pp

(pore pressure) as there are no pores to transmit this pressure

against the frac fluid.

If

crossed dipole sonic data is available, anisotropic stress can

be noticed by differences in the X and Y axis displays of both

the compressional and shear travel times. When this occurs, all

the elastic constants can be computed for both the minimum and

maximum stress directions. This requires the original log to be

correctly oriented with directional information, and may require

extra processing in the service company computer center.

Sample fracture pressure gradient log

Calibrating Fracture Pressure Gradient

Calibrating Fracture Pressure Gradient

Because

so many assumptions are made in computing elastic constants and

pressure gradients, calibration is essential. If all the corrections

for frequency, gas, dynamic to static, anisotropy, and so on are

performed first, the correction factors may be relatively small.

The cause for error may even become apparent and the correction

might be made to Poisson's Ratio or overburden pressure. However,

the more usual case is that the cause is unknown. Because

so many assumptions are made in computing elastic constants and

pressure gradients, calibration is essential. If all the corrections

for frequency, gas, dynamic to static, anisotropy, and so on are

performed first, the correction factors may be relatively small.

The cause for error may even become apparent and the correction

might be made to Poisson's Ratio or overburden pressure. However,

the more usual case is that the cause is unknown.

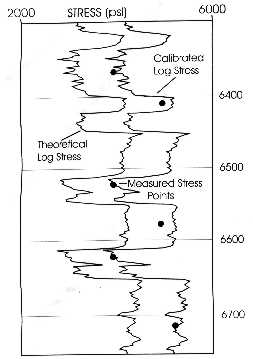

A

common correction method is to compare log analysis stress profiles

with individual results from single or multiple mini-fracs. The

correction may be a linear shift of the log derived curve, such

as the example in the log at the right.

Mini-fracs

or leak-off tests should be run to verify that the computed fracture

pressure is close to the leak-off pressure. These tests are also

called pump-in tests. If they are not equal, then

there is anisotropy or tectonic stress (Pext). Alternatively,

some of the data or assumptions that went into calculating Po,

Pp, Pfrac, PR, or ALPHA might be wrong. The math should be iterated

to obtain a good match to the mini-frac without resorting to unreasonable

gradients or rock properties.

Leak-off pressure test versus time

Fracture pressure gradient log showing shift to match

measured

closure stress (black dots).

An

alternative fracture pressure approach ignores all the log derived

data. Since the calculation must be calibrated anyway, why not

calibrate directly to available mini-fracs, and ignore the log

data? Mike Cleary proposed the following equation:

19: Pfrac = A * Po + B * Pp + C

Where:

A, B, C are constants derived from regression with pressures from

mini-fracs.

This

approach only works when sufficient tests exist over a moderate

depth range. It is of course useless where there is no test data.

It also loses a lot in translation, since the underlying physics

is hidden from view.

Because

of the major improvements in measuring shear sonic travel time

that have occurred in the last 10 years or so, and the recognition

and measurement of anisotropy in acoustic properties, many of

Cleary's complaints about elastic properties from acoustics have

disappeared. His ABC method may not need to be invoked as often

as in the past.

My

advice is try the log analysis method first if decent modern data

is available. Calibrate results to mini-fracs. Try and find the

sources of errors and fix them. When there is no decent log data,

use Cleary's ABC approach.

Calculating Fracture Extent

Calculating Fracture Extent

Programs for fracture design are commonly called "frac height"

programs, but fracture extent (width) and fracture aperture are

also vital results. The math for this software is a little complicated

for this Chapter, and we assume you have a commercial software

product to perform the work. Accurate elastic constants and pressure

values derived as in previous Sections will be needed, and calibration

will still be required.

The modern use of the elastic properties and fracture pressure

gradient data in the computer creates some very impressive colour

displays to present the hydraulic fracture design to potential

customers. The same data can be entered into 3-D

modeling programs and compared to real frac jobs to assist in

frac job optimization.

FracHite log (left)

FracHite log (left)

|

Fracture optimization model

Fracture optimization model

|

Gamma Ray Logging to Confirm Fracture Placement

Gamma Ray Logging to Confirm Fracture Placement

To determine where a hydraulic fracture really goes into a formation,

some of the propping material can be coated with radioactive tracer

materials. After the fracture stimulation treatment is finished,

a standard gamma ray log is run to locate the tracer elements.

A base log must be run before the fracture stimulation to make

comparison easy.

The

fracture height determined from observation of the gamma ray log

is used in type-curve-fit or simulation software, with the treatment

placement pressure curve, to calculate fracture length (depth

of penetration). The fluid plus proppant volume is used in the

simulation to calculate fracture width (aperture).

Some

fracturing companies use a spectral gamma ray logging tool to

locate different radioactive tracer elements that have been applied

to different sized propping materials. The finer sized proppants

will show the deepest penetration, with coarser material being

deposited closer to the wellbore. The spectralog gives a 3-D image

of the fracture length, height, and width (aperture). These tracers

have very short half-lives (hours or days) so no permanent radioactive

signature is created).

Post-frac radioactive tracer log with natural gamma ray in

Track 1 recorded before stimulation. Tracer log in Tracks 2 and

3 shows some placement into both sets of pwefs, but alsp above

upper perfs, possibly due to channel in cement behind casing.

The

gamma ray curve amplitude is a qualitative indicator of fracture

width (a

perture) since the quantity of radioactivity is proportional

to the volume of proppant that carries the tracer elements.

Note

that after a period of production from any reservoir, there may

be a permanent radioactive anomaly caused by precipitation of

uranium salts. A gamma ray log run in this situation helps to

identify where fluid flow is occurring. Some remedial action may

be possible if flow is not as expected. Some naturally fractured

reservoirs show this anomaly before production. In this case,

the precipitation occurred during migration of the hydrocarbon.

If

a producing or naturally fractured reservoir is to be hydraulically

fractured, a baseline gamma ray log should be run before the job.

The post-frac tracer log should be compared to this baseline,

rather than the original open hole gamma ray log.

Determining Fracture Orientation

Determining Fracture Orientation

As mentioned above, when formation pressure is isotropic (equal

in all directions), the tectonic stress is zero and Pfrx equals

Pfry. In this situation, the borehole is round and spalling of

the formation is either non-existent or equal in all directions.

In stressed regions, such as in the Rocky Mountains, the borehole

will erode to an oval shape. The minimum diameter shows the direction

of maximum stress and the maximum diameter shows the direction

of minimum stress..

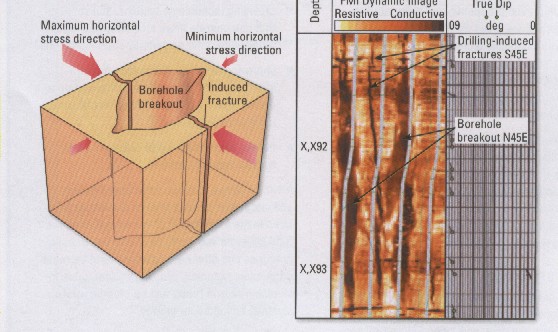

Borehole shape indicates stress direction –

maximum stress in direction of minimum hole

diameter. Formation microscanner and dipmeters have oriented caliper data.

Many

modern logs have an X and Y axis caliper, but not all of them

are oriented to true north. When directional data is recorded,

as with dipmeters and many modern resistivity tools, the X and

Y orientations are known, Statistical plots are helpful in choosing

the dominant direction).

Borehole diameter indicates stress direction -

this example is from India where the minimum

stress direction

is NE - SW.

A

hydraulic fracture will usually penetrate the formation in a plane

normal to minimum stress, or parallel to the plane of maximum

stress. Any stress anisotropy (tectonic stress) will cause the

fracture to be other than vertical. A

hydraulic fracture will usually penetrate the formation in a plane

normal to minimum stress, or parallel to the plane of maximum

stress. Any stress anisotropy (tectonic stress) will cause the

fracture to be other than vertical.

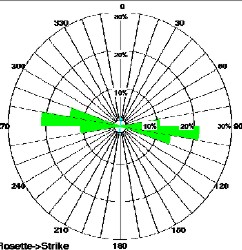

Natural

fractures take the same directions as hydraulic fractures, indicated

again by the borehole shape. In addition, the high angle dips

seen on an open hole dipmeter or image log, will also indicate this preferential

direction. Since most hydraulic fracture jobs are run in casing,

it is not possible to run a dipmeter or caliper survey to find

the orientation of a hydraulic fracture. The preferential direction

can be predicted from previous open hole data. Dipmeter and caliper

data can be displayed on rose diagrams to illustrate preferential

directions.

If

an azimuthal gamma ray log existed, the fracture orientation could

be located by a tracer survey. I am not aware that such a tool

exists, but it would not be difficult to design one..

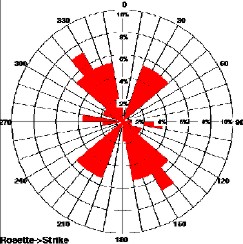

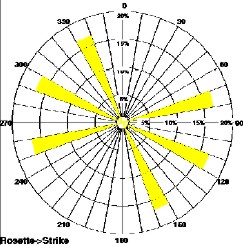

Azimuth frequency (rose diagram) plots show direction of

dips seen on dipmeter and image logs. When steep dips caused by

fractures are isolated from lower angle bedding dips, the

direction of maximum stress xan be determined. In this case, the

direction is N30E. Azimuth frequency (rose diagram) plots show direction of

dips seen on dipmeter and image logs. When steep dips caused by

fractures are isolated from lower angle bedding dips, the

direction of maximum stress xan be determined. In this case, the

direction is N30E.

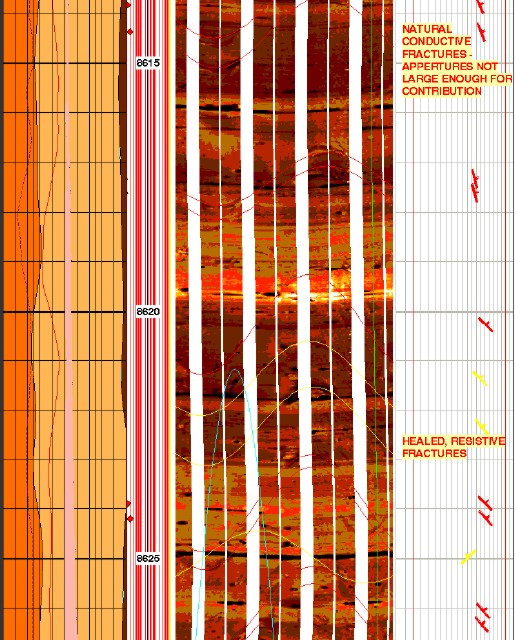

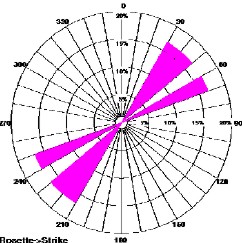

Stress

direction is not constant over geological time scales. Differences

in the direction of induced fractures (present day stress

direction), open fractures (some time ago), healed fractures (older

than open fractures), and small faults (could be any age) will help

to show the stress history of a region. An example log and rose

diagrams are shown below.

Image log in fractured reservoir: gamma ray (left track, shaded

red), image track (middle) with open fractures (red sine waves and

healed fractures (yellow sine waves), dip track (right) shows red

amd yellow dip angle and azimuth. There are no induced fractures in

this short interval. Bedding planes are near horizontal. Imagine

trying to locate these steep dips without the aid of a computer.

.

Induced fractures (top left) show current stress direction. Open

fractures (top right) show stress direction when fractures were

created, healed fractures (lower left) show different direction at

an earlier phase in geological time, and micro faults (lower right)

shows another stress regime was present when the faults occurred.

The

newest dipole shear sonic log is also an azimuthal tool with dipole

sources set at 90 degrees to each other. The example below shows the shear images for the X and Y directions. This

log can be run in open or cased hole.

Dipole shear image log shows directional stress

- the Fast Direction is centered on

90 degrees (east - west) which

is also the maximum stress direction.

Resistivity and acoustic image logs also provide assistance in locating fracture orientation before the well

is cased.

|