|

PIPE RECOVERY BASICS

PIPE RECOVERY BASICS

Portions of this page are from Petroleum Engineer's Handbook

(PEH) online version.

Pipe recovery refers to a type of wireline operation to

assist

retrieval of drill pipe, tubing, or production casing

that is stuck in the hole. In this situation, the drilling

rig or pulling unit is unable to retrieve the pipe out of

the hole and a mitigation process called pipe recovery has

to be utilized. Pipe can become stuck in a well bore in both

open hole drilling operations as well as work-over

operations in cased hole. The goal of pipe recovery is to

retrieve as much pipe as possible to save the operator the

expense of replacing pipe and reduce the amount of lost hole

/ depth of well. Pipe recovery needs to be quick and precise

in the determination of free pipe vs stuck pipe. Every

minute a rig is down not operating is lost money to an oil

and gas operator.

Mitigation of stuck pipe is a step-by-step process:

1. Run free point indicator log on wireline to find top of stuck

pipe; this is the depth above which the pipe must be cut off so that

the free pipe can be retrieved.

2. Choose appropriate pipe cutting tool for the situation.

3. Run pipe cutter on wireline to a depth above free point depth

and cut the pipe.

4. Pull free pipe out of the hole.

5. Optional: run drill pipe with appropriate overshot to attempt

to retrieve remaining stuck pipe.

Close coordination between oil company engineer, rig crew, and

wireline crew is a critical part of a successful pipe retrieval

project.

Causes Of Stuck Pipe

Causes Of Stuck Pipe

Situations that cause pipe to become stuck in open hole are:

Blowout: when the hydrostatic pressure of the drilling mud is lower

than the formation pressure, it is possible for formation fluids and

debris to move up the hole. This action creates an increase in pipe

friction and can wedge the pipe, causing it to become stuck in the

hole.

Differential Pressure: when the hydrostatic pressure of the drilling

mud is higher than the formation pressure, fluid begins to flow into

the formation. This causes the pipe to be sucked to the borehole

wall and unable to move.

Sloughing Hole: this happens when the stability of the borehole is

weak and breaks down. Once it breaks down, gravity goes to work

pulling the well debris down the wellbore, wedging the pipe in the

hole.

Swelling Formation: the formation reacts with the wellbore

fluids,acting like a sponge and swelling outward,, pinning the pipe

in the borehole wall.

Crooked or Bent Pipe: during drilling operations the pipe becomes

fatigued, causing the pipe to bend and torque up. This creates a

situation where the pipe pins itself on the walls of the well bore

and unable to rotate or be pulled out of the hole.

Key-seating: when the drill string becomes buried into the wellbore

walls in a deviation point or in a dog-leg area. Good indication of

this is the rig can push pipe in the hole but when pulling up it

starts pulling tight. If severe enough, the pipe will not be able

to move either direction. Example of this is pulling a rope over the

edge of a dirt hole. The more you pull on it the deeper the rope

cuts into the edge of the hole.

Common cased hole sticking issues:

Wrap Around: dual string completions, two strings of production

tubing are run in the hole with a dual packer to produce from

multiple intervals without comingling during production. When a work

over rig attempts to pull one string, they are unable to do so due

to the two strings wrapped together on bottom near the packers. The

pipe is unable to pull free from the packer.

Mud on back-side: when attempting to pull a single well completion,

the mud on the backside of the tubing has dried or settled out. This

creates a situation that is like having the pipe cemented in the

hole. The pipe is unable to move, and it is not possible to

circulate out due to density. Even if circulation hole is put in

pipe in area, you will be unable to pump in to remove debris.

Packer Seal: in a workover operation, the operator attempts to pull

the production string out of the packer. It is not uncommon in

older wells for the tubing to become affixed to the packer and

unable to move.

Collapsed Casing: as the name implies, the casing collapses due to

external strain or fatigue of the pipe. This pinches the production

string, not allowing the pipe to be moved.

Cemented String: in some older production practices, the tubing

string was cemented in place. The only way to remove is to perform

Pipe Recovery operation.

Junk: this pertains to a wide variety of possible causes. Often

debris from the well head installation wedges or pinches the pipe to

the casing wall. Some examples: bolts, wrenches, and other well bore

debris falling on top of the packer. Holes in production string can

allow formation debris to build up on the backside of the production

tubing.

Free point Indicator ToolS

Free point Indicator ToolS

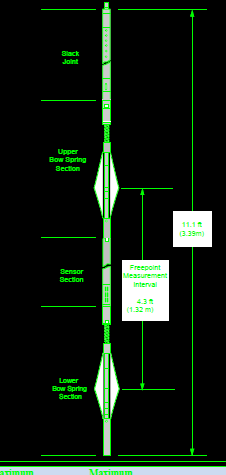

The free point tool is composed of several measurement components:

Casing collar locator (CCL),

Strain gauge to measure pipe stretch when an attempt is made to pull the

pipe,

Another to measure rotation or torque when an attempt is made to rotate

the pipe,

The

tool has an upper and lower part, each with motorized, spring

loaded, or magnetic anchors. The two parts are connected by a slack joint.

Relative motion, vertically or rotationally, between the two parts

is recorded by the sensors and sent uphole to the surface recorder.

Relative motion when tool is anchored, and rig is attempting to pull

or rotate the pipe, indicates free pipe. The

tool has an upper and lower part, each with motorized, spring

loaded, or magnetic anchors. The two parts are connected by a slack joint.

Relative motion, vertically or rotationally, between the two parts

is recorded by the sensors and sent uphole to the surface recorder.

Relative motion when tool is anchored, and rig is attempting to pull

or rotate the pipe, indicates free pipe.

Since this is a station-by-station measurement, common practice is to

take a reading near surface. With this set of stretch and rotation

data, and the pipe specs, an initial estimate of free point depth is

made. The tool is then run downhole from surface to some depth below

estimated free point, logging the casing collars on the way down.

Once the tool is in the stuck depth intervao, the

station-by-station

operation is performed moving uphole until the depth of 100% free pipe is determined more

precisely. This is the depth at which the pipe cutter will

be set after the free point tool is pulled out of the hole and laid

down. Some tools can be combined with back-off shots, saving rig

time.

Altermate tool designs may be in ose in some areas. An acoustic tool

identical to a cement bond log (CBL) may be used for drill pipe or

casing. As for cement, low amplitude at the receiver means stuck

pipe, high amplitude means free pipe.

Another type uses sensors that measure the changes in the pipe's

magnetic properties when stretch or torque are applied. It provides

fast and precise free-point location without the repetitive stop and

set measurements of traditional free point indicators..

Back-off / String Shots

Back-off / String Shots

Back-off is the preferred method of freeing a drill string from a

stuck bottom hole assembly. It is the least destructive to the down

hole assembly and allows for multiple options for recovery if

desired. The basic concept is to simply unscrew the pipe at a

desired depth of 100% free pipe. The driller will apply “Left Hand

Torque” to the drill string and lock in with the tongs while holding

the string in the elevators. This is based on pipe type, torque

specs, collar connections, and desired back-off depth. A wireline

“string shot” is prepared based on the parameters for the current

operation. A specific amount of prima-cord is run in the hole to the

desired depth and detonated. This creates a hammer affect releasing

the tension in the collar and allowing the pipe to unscrew, freeing

the pipe and making it possible to move the pipe out of the hole,

once the wireline is pulled out of the hole and laid down.

Casing and Pipe Cutting Tools

Casing and Pipe Cutting Tools

Casing cutters come in a variety of types and sizes to suit the

situation. Here is a brief description of the common varieties.

Jet Cutter

Jet Cutter

A jet cutter is a radial shaped charge, allowing a blast to be

created in a 360deg direction to cut the pipe or tubing. Generally,

the tool diameter is close to the internal diameter of the pipe to

be cut.

Example

of a Jet cutter tubing cut.==> Example

of a Jet cutter tubing cut.==>

Considerations:

** What pipe am I cutting? Best tool for the purpose?

If you are cutting light weight drill pipe and or tubing a jet

cutter will work well.

** Is the bottom hole assembly going to be fished?

The standard jet cutter will flare the pipe outward due to the

explosive pressure created, making fishing operations difficult and

require an extensive remedial operation prior to fishing. Several

pipe trips will be required to dress off or mill the top of the fish

enough to allow an over shot to be run. If fishing and a jet cutter

is preferred, consider a Premium cutter. This cutter will cut the

pipe cleanly with minimal amount of pipe distortion, making it

easier to fish with a burn over mill and over shot to dress off top

prior to latching fish.

** Will I be able to maintain tension on the drill string /

production string during cutter ops?

Standard cutters require tension on the pipe to insure a complete

cut. Even then, there are some situations where the pipe will not

be cut completely, and an addition cutter run will be required. If

so, do not cut in same place, move up the hole to fresh pipe to

re-attempt cut.

** Is there enough stand-off distance of the intended string to be

cut?

It is possible for a jet cutter to damage the casing if cutting

pipe that has little to no collar connection stand-off.

** Are there any restrictions inside the assembly that would prevent

the cutter from getting to depth?

The jet cutter is a large diameter tool, specifically designed to

cut the drill pipe/tubing desired. If there are any restrictions,

jewelry, or couplers the ID measurements need to be reviewed before

running in.

Chemical Cutter

Chemical Cutter

A chemical cutter is a controlled high-pressure dispersion of

bromine trifluoride. It creates a highly corrosive environment when

mixed with water, causing a chemical reaction to rust the pipe at an

accelerated rate. There is no debris and no pipe distortion after

cutting, making fishing operations less complicated.

Example

of a Chemical Cutter tubing cut. ==> Example

of a Chemical Cutter tubing cut. ==>

Considerations:

Does not work in mud environments. Sensitive to high hydrostatic

pressures.

Radial Cutting Torch

Radial Cutting Torch

A radial cutting torch is a plasma cutter that creates a clean cut

of various pipe types. It does not require fluid in the well or

clear fluid. It works in almost all fluid systems currently in use

for drilling or production operations. It is a non-explosive tool

and does not require any special shipping restrictions for

commercial air lines. This reduces cost and delays getting tools to

a well site.

Example

of Radial Cutting Torch. ==> Example

of Radial Cutting Torch. ==>

Considerations:

Cost of radial cutting torch. Timing of availability for

application.

Split Shot

Split Shot

The split shot is a linear shape charge designed to split a collar

connection, allowing the pipe to slip out of the box connection.

Magnets are run in conjunction to hold tool in position while cut is

made. It is a great option when ID restriction prevents a

traditional jet cutter from being run, due to the slim design of the

tool. The main drawback is the tool must be positioned across the

collar to be effective.

Example

of a Split shot cut. ==> Example

of a Split shot cut. ==>

Considerations:

** Can a jet cutter be utilized?

** Is well deviated and is it possible to accurately place tool in

desired location?

Severing Tool / Colliding Tool

Severing Tool / Colliding Tool

A severing tool or colliding tool is a last resort application for

cutting pipe. It is primarily used on heavy weight drill pipe or

drill collars. It is completely destructive and blows the pipe apart

(bomb downhole). There is two explosive charges at either end of

the tool. When detonated they both explode creating a shock wave

that meets in the middle section of the tool blasting the pipe in

two.

Example

of Severing Tool ==> Example

of Severing Tool ==>

Considerations:

** Is BHA being left in hole?

Extremely difficult to fish.

|