Petrophysical Training

Licenses

|

PERFORATING BASICS

PERFORATING BASICS

Portions of this page are from Petroleum Engineer's Handbook

(PEH) online version.

A

perforation, in the context of oil or gas production, refers

to a hole through the casing and cement sheath into the

reservoir rock, allowing fluids to flow into the wellbore.

The depth interval to be perforated is determined by the

results of a competent petrophysical analysis of potential

reservoirs, aided by local field experience and regional

geological knowledge.

Perforations are created in a wellbore by specially designed

explosives carried by a perforating tool, sometimes called a

perforating gun.

Where possible, perforating tools are run on wireline. After

placing the perforating tool at the desired depth,

electrical signals from the surface fire the explosives. In

deviated and horizontal wells, coiled tubing may be used to

convey the tool. Newer technologies allow the tools to be

run on slickline, using embedded fiber optic lines to

trigger tool operation. Less commonly, they can be run on

tubing or as part of the casing string.

There are two main types of wireline perforators. One

uses black powder with steel bullets, developed in the 1930s, to

“shoot” holes through the casing. The other, using shaped charges

developed from military “armour-piercing” science, became available

after 1946; this is the most common perforating tool today.

Typical tools create holes of 6 to 24 inches in depth by about 1/2

inch in diameter, with shaped charges giving deeper penetration.

Shots are spaced a few inches to a foot apart, often 4 shots per

foot (4 spf) or 13 shots per meter (13 spm).

The bullet gun creates some microfractures around the perforation

in the rock, increasing near wellbore permeability. Shaped charges

reduce near wellbore permeability, so a small acid or hydraulic

fracture stimulation is often applied to mitigate this drawback.

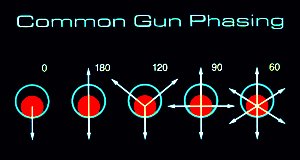

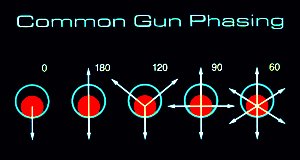

The radial angle between the shots is called the phasing. The most

common phasings are 0°, 180°, 120°, 90°, and 60°. A hundred or more

perforations can be made in a single run into a well.

Alternatives to explosives also were implemented, normally with an

abrasive slurry of material such as frac sand and a carrier liquid.

Abrasive perforating methods are slower, require a rig, and contain

several wear points in the treating equipment.

Planning,

tool selection, and wellsite implementation are critical steps to a

successful perforating job. Planning,

tool selection, and wellsite implementation are critical steps to a

successful perforating job.

The following tool descriptions are highly condensed from a

Wikipedia article, with some editing for clarity.

Bullet gun perforators

Bullet gun perforators

Projectiles (bullets) from these perforating tools

must penetrate the casing, cement, and formation. Penetration is

easiest in low alloy, thin wall pipe. Penetration in higher strength

casing and harder formations is more difficult in most cases and not

feasible in others. When successful, the bullet creates a very round

entrance hole but may create a hole with sharp internal burrs.

Perforation length drops sharply with increasing formation

strength, with extremes of 15 inches in soft chalk to only 2 to 3

inches in dolomite. In contrast to shaped-charge perforating,

however, bullets often shatter the rock rather than smoothly push

back and compact the rock in their path. The shattering can be a

definite advantage when the cracking improves the permeability next

to the perforation.

Shaped charge perforators

Shaped charge perforators

These perforators come in two basic flavours:

retrievable hollow carriers and expendable strip carriers.

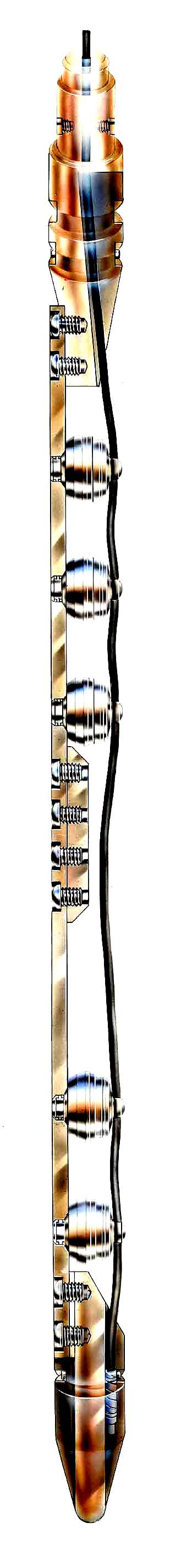

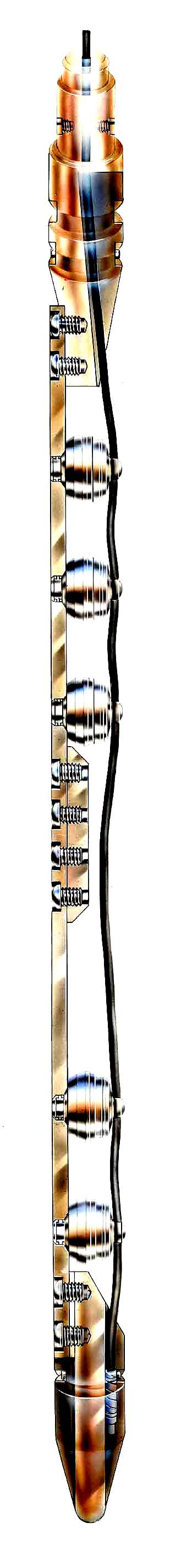

<== Expendable

shaped charge carrier (left), Hollow shaped charge carrier (right)

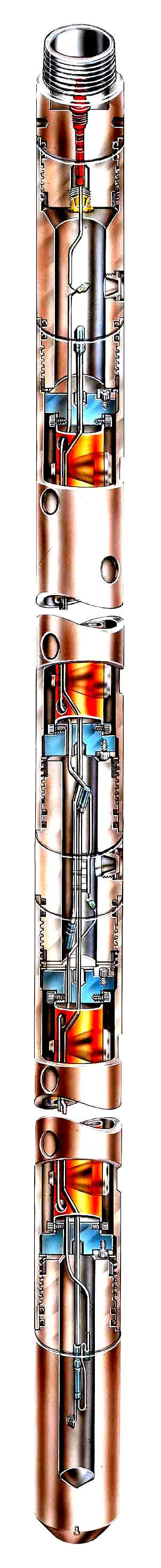

Retrievable hollow carrier perforators are tubes that contain the

shaped charges and ignition system, and can be run either on

wireline or tubing. They can carry large charges and the tool mass

absorbs some of the recoil, minimizing casing damage. The carrier

contains most of the debris from the charge and alignment system,

leaving little trash at bottom hole.

They can be small size, able to pass through tubing and

restrictions, or larger sizes that are run through casing, conveyed

by either wireline, work string, or the production tubing. Both

reusable and single use tools are offered.

Hollow carriers, depending on their diameter and design, may be

loaded with 1 to 27 shots/ft and have all the commonly used phase

angles, as well as specialty phasings.

On larger diameter, thick wall hollow carriers, there is much less

distortion caused by the shots than on the small, thin wall through

tubing tools. In wells with tight clearance between carrier and

tubulars, the amount of distortion of the tool should be determined

from the service company before use. Some tools have shallow

scallops at the shot locations so that shot distortion will not

exceed the nominal tool diameter.

Expendable Strip Perforators have shaped charges that are exposed to

well fluids and pressures. They are popular for through tubing

applications, but are more vulnerable to damage. Without the bulk of

the hollow carrier body, larger charges can be run through any given

small or buckled tubing restriction.

The charges are linked together by a common strip, wire/cable, or a

linked body design. The expendable tools force the casing to endure

a much higher explosive load during firing because the recoil is not

contained in a sacrificial shell as in a hollow carrier. Casing

splits are sometimes seen after perforating in cased holes with poor

cement or low-strength casing.

Expendable tools are used because their perforating performance is

significantly better than hollow-carrier tools in the smaller

diameters.

When the charges are fired, some or all the linking materials, as

well as the charge capsule remnants, are left in the hole.

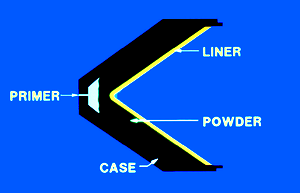

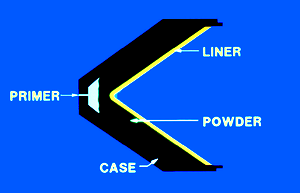

Shaped

charge concepts

Shaped

charge concepts

The shaped charge or “jet” perforator

uses a small amount of high explosive and a carefully shaped case

and liner to create a focused pressure wave that is highly effective

in piercing steel, cement, and rock. The jet is formed through a

highly critical but reliable sequence of events, beginning with the

firing of the initiator or detonator cap, which ignites the

detonation cord running through each shaped charge, followed by the

initiation of each charge.

As the explosive front moves through the charge, it

strikes the apex of the liner deforming the liner and fluidizing

part of its mass into a focused jet that punches a hole through the

material in its path.

As the jet forms, it stretches out with the jet tip approaching

speeds of 6100 m/s (21,000 ft/sec), and the tail of the jet

traveling at approximately 3,000 m/s (11,000 ft/sec). The jet is not

hot and does not burn or melt anything; it can pierce a book leaving

no scorch marks, just compressed paper around the hole.

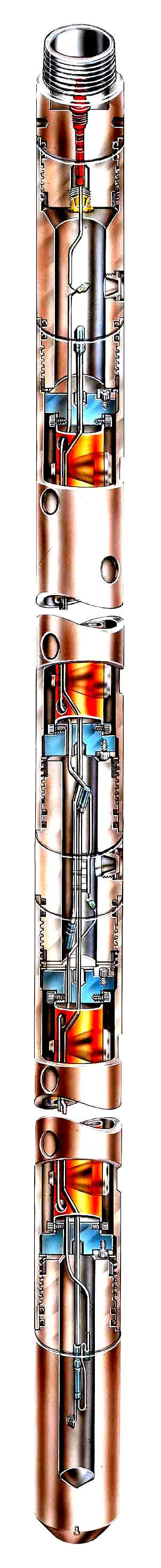

Shaped Charge

Carrier

Parts of a shaped charge (left), X-ray of a 20-g charge (middle),

Jet formation (right)

Detonator safety systems

Detonator safety systems

Once on depth, charges are fired

by an initiator or detonator. Any wireline conveyed, hollow carrier

perforator should have a detonator system that will not allow the

charges to fire if the gun is completely or partially filled with

water. If a water filled hollow-carrier gun is fired, the outer body

shell may rupture and result in a fishing or milling job.

Specialized detonators have methods of preventing wet (fluid filled)

gun firing, as well as offering a number of other safety benefits

ranging from resisting stray currents, such as static and radio

energy, to pressure switches that put the tool in safe mode to

prevent accidental surface firing.

Although the standard explosive detonator, also called a blasting

cap, is a mainstay of the construction industry, it is not well

suited to the petroleum industry. Instead, the resistor detonator is

used, incorporating resistors that reduce the possibility of

discharge from low-power electrical signals.

Abrasive perforating methods

Abrasive perforating methods

Abrasive perforating uses high

volume flow of abrasive laden fluid to erode through the target pipe

or cut it off when the nozzle or tubing string is rotated. Abrasive

impingement of hard particles such as sand on steel can cut through

0.25 to 0.3 in. of casing in a matter of minutes. Perforations in

the casing or even 15 × 1.2 cm (6 in. × 0.5 in.) slots can be formed

within 10 to 20 minutes per slot.

Abrasive methods often use a shaped nozzle that focuses the stream

on the steel surface. The nozzle helps preserve energy, shorten

cutting time, and decrease the effect of clearance distance, but the

nozzle wears with use.

Perforation depths formed by abrasives are typically short because

the returning fluid and solids interfere with the ability of high

pressure fluids to access deeper targets. Depths of 2.5 to 23 cm (1

to more than 8 in.) have been measured in tests performed with

backpressure.

Abrasive perforating in surface targets often produces quicker

cutting and deeper perforation depth, but these tests are not a

valid representation of tool performance in a well. Adding

backpressure on any type of a jetting tool rapidly diminishes its

performance.

Required equipment includes a rig with tubing large enough for the

required rate with minimal friction drop. A fixed nozzle for

perforating or a rotating nozzle for abrasive cutoff is the main

bottomhole assembly.

|

|

Planning,

tool selection, and wellsite implementation are critical steps to a

successful perforating job.

Planning,

tool selection, and wellsite implementation are critical steps to a

successful perforating job.