|

DEPTH CONTROL BASICS

DEPTH CONTROL BASICS

Portions of this page are from Petroleum Engineer's Handbook

(PEH) online version.

Depth is the most

important measurement made in relation to well

log data

acquisition. Accurate depth measurements allows for

information to be compared to the wellbore and across

multiple wells in a field. There are several types of data

from geology, drilling measurements, completion and

production operations that use depth as a normalizing tool.

t allows all the phases of a wells life to be correlated to

the reservoir or zone of interest. Small errors will have a

great impact on the success of a well. Therefore, depth

control during logging, completion, and work over is

critical to make sure it is correct and consistent.

Correlating wireline depths in a shallow well or a vertical

well are normally a simple task to perform. However, as the

depth, deviation, and complexity of the well bore increases,

it is more critical to have a good understanding of the

principles of depth control. Understanding the principles

will allow you to identify issues and corrective actions

that can be taken to insure success.

The main

consideration is appropriate logging speed to reduce variations in

cable tension caused by tool drag. Depth control in a cased hole

operatiom usually involves correlation between one or more cased

hole logs with existing open hole logs. Hence, the speed must be

slow enough that the resolution of events on the gamma ray (GR),

collar locator (CCL), and neutron log (if run) is sufficient to

identify the characteristic log response of the depth interval to be

completed or serviced. Make sure the open hole base log is correct

for the well you are working on.

Collar Locator Log

Collar Locator Log

The two primary cased hole

logging tools used for deoth control are the gamma ray (GR) and the

collar locator (CCL). The GR can be correlated with previous open

hole logs to tie into the reservoir zone of interest. The CCL, run

in tandem with the GR, is used to tie in the drillers pipe tally to

the logger’s depth measurements.

All

collar locators work on the basis of Faraday's law. Each collar

locator (CCL) has a coil with a magnet located at each end. The

magnets create a fairly large magnetic flux which surrounds the

coil. When a CCL is traveling down hole, the changes of pipe mass at

the end of each pipe joint (the pipe collar) disturbs the flux of

the CCL. As the flux changes, a voltage is created in the coil. All

collar locators work on the basis of Faraday's law. Each collar

locator (CCL) has a coil with a magnet located at each end. The

magnets create a fairly large magnetic flux which surrounds the

coil. When a CCL is traveling down hole, the changes of pipe mass at

the end of each pipe joint (the pipe collar) disturbs the flux of

the CCL. As the flux changes, a voltage is created in the coil.

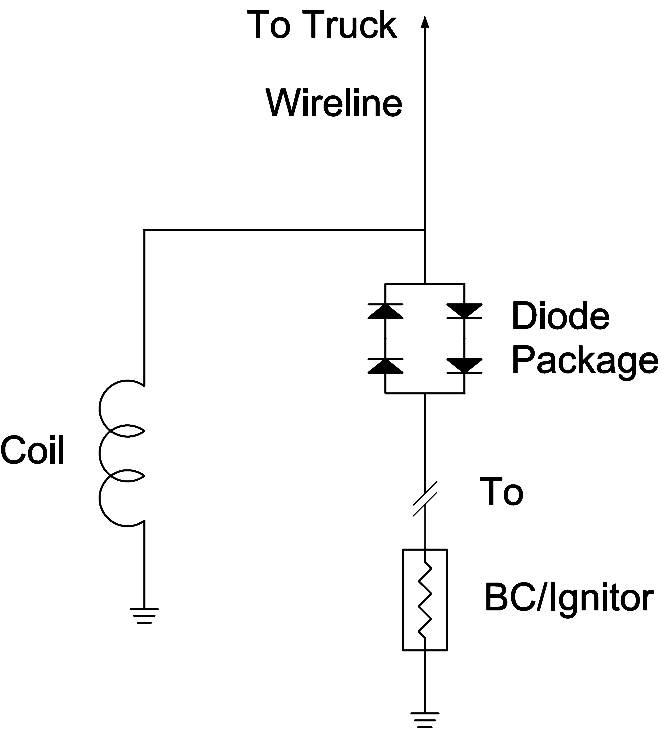

Circuit diagram for a Collar Locator log ==>

At this point, what

happens to the signal depends on what type of CCL is being used,

either powered or non-powered. In the non-powered CCL, the voltage

is placed on the wireline and travels up-hole to the logging unit.

Diodes prevent the signal from travelling through the mud to the

sueface.

In the powered CCL,

the voltage is passed to an amplifier circuit in the CCL tool and

then the amplified signal is placed in the wireline and sent to the

surface computer to be processed.

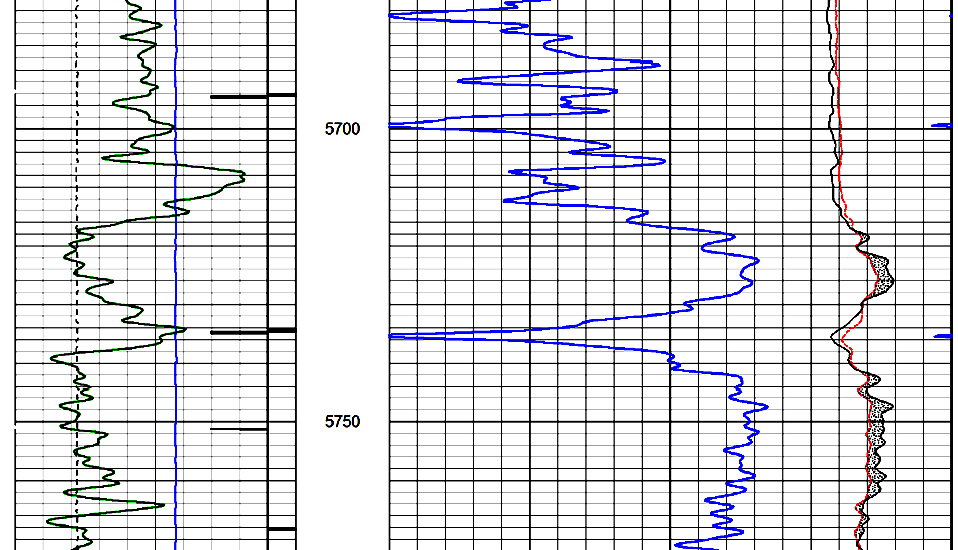

Example of a Collar Locator log – large, sharp peaks are generated

by changes in pipe mass, for example pipe joint collars or broken,

heavily corroded or gaps in the pipe.

Gamma Ray Logging Tool

Gamma Ray Logging Tool

The gamma ray logging tool

measures natural radiation emitted from rock formations traversed by

the logging tool. Shales and clays have higher radioactive count

rates than the usual reservoir rocks (quartz, calcite, dolomite) due

to potassium and thorium. Many unconventional reservoirs and source

rocks contain uranium as well as potassium and thorium.

On the log, low GR

values arw toward the left side, usually in Track 1. A GR curve

spanning Tracks 2 and 3, with low values toward the right, is

sometimes presented to aid correlation to open hole porosity logs.

A cased hole GR log

may be scaled in counts per second (cps) or APIgr Units. The APIgr

scale may or may not be calibrated, and if calibrated, may or may

not have casing and borehole size corrections applied. Read the log

heading carefully.

A cased hole neutron

log may also be run with a GR / CCL depth control log. It can be

scaled in counts per second, APIn Units, or porosity units (% or

decinal fraction), spanning Tracks 2 and 3. In all cases, low

porosity is toward the right and high porosity and shale to the

left.

The shape of the

cased hole gamma ray log curve is used to correlate depths with the

open hole logs. The depth recording system in the logging unit is

manually adjusted so that cased hole depths match open hole logs.

Then and only then can the planned completion or work over proceed.

Example of a gamma ray log (Track 1) with collar locator. A

neutron log spans Tracks 2 and 3. The neutron near and far count

rates are at the right hand side of Track 3.

Types of Cased Hole Gamma Ray

Detectors

Types of Cased Hole Gamma Ray

Detectors

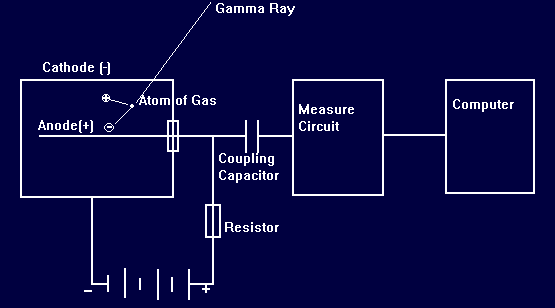

A Geoger-Mueller detector

is an ionization chamber that contains a low pressure gas and has a

high voltage applied to the electrodes. A gamma ray strikes an atom

of gas and causes a positive and negative ion to be formed. Because

of the high voltage that has been applied to the electrodes, the

ions accelerate toward their respective electrodes and in the

process strike other gas atoms, creating more ions. The effect is a

multiplication takes place (Townsend Avalanche). Eventually the ions

strike or reach the lectrodes producing a current or pulse which is

roportional to the amount of ionization produced in the gas volume.

The current produces

a voltage drop across a resister. The voltage drop is coupled as a

negative pulse into an amplifier circuit, sent up the wireline,

detected by the computer and counted over a short time interval. The

computer translates the number of pulses into a curve on the log.

This type of tool is

often called a Gun Gamma Ray as the tool is rugged enough to survive

the detonation of perforating guns and other explosive devices.

Schematic diagram

of Geiger-Mueller detector

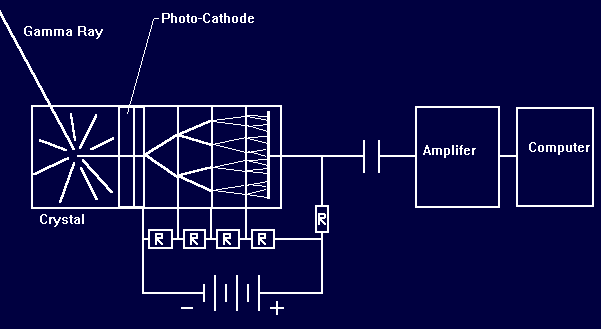

The scintillation

gamma ray detector is much more efficient and thus more sensitive

than the Geiger-Mueller detector. The detector consists of a sodium

iodide crystal and a photomultiplier. When a gamma ray enters the

crystal, a photon (a tiny speck of light) is emitted. The

photomultiplier amplifies this tiny pulse into a useable electrical

signal that can be sent up the wireline to the computer. The crystal

degrades with rough handling and shocks so, depending on tool

design, it may not be suitable for all cased hole applcations.

Schematic diagram of NaI Scintillation detector

Some Definitions

Some Definitions

Dead time is the interval

of time where the detector is incapable of responding to a

second incoming gamma ray.

Resolve time is the

time between two barely recordable pulses.

Variation of count

rate due to the random disintegration of radio-active material are

called statistical variations. It is reduced by averaging the raw

output from the GR tool over a specific distance or time interval

using an averaging formula. The longer the filter distance, the less

defined the formation bed boundaries are on the log. Typical filters

are 1 or 2 seconds long and logging speed is set so that this time

represents 2 or 3 feet of travel. G-M detectors need longer time

constants and slower logging speeds to achieve a good quality log.

|