|

GEOCHEMICAL ANALYSIS BASICS

GEOCHEMICAL ANALYSIS BASICS

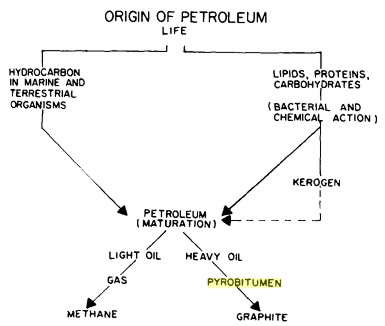

Geochemical analysis is used to determine the type and

quantity of organic carbon and other properties of

unconventional reservoirs and source rocks. Organic carbon

in the form of kerogen is the remnant of ancient life preserved in

sedimentary rocks, after degradation by bacterial and chemical

processes, and further modified by temperature, pressure, and time.

The latter step, called thermal maturation, is a function of burial

history (depth) and proximity to heat sources. Maturation provides

the chemical reactions needed to give us gas, oil, bitumen,

pyrobitumen, and graphite (pure carbon) that we find while drilling

wells for petroleum.

Organic

carbon is usually associated with shales or silty shales,

but may be present in relatively clean siltstone, sandstone, and carbonate rocks.

A source rock is a fine grained sediment

rich in organic matter that could generate crude oil or natural gas

after thermal alteration of kerogen in the Earth's crust. The oil or

gas could then migrate from the source rock to more porous and

permeable sediments, where ultimately the oil or gas could

accumulate to make a commercial oil or gas reservoir.

If a source rock has

not been exposed to temperatures of about 100 °C, it is termed a

potential source rock. If generation and expulsion of oil or gas

have occurred, it is termed an actual source rock. The terms

immature and mature are commonly used to describe source rocks and

also the current state of the kerogen contained in the rock.

Total organic

carbon (TOC) as measured by laboratory techniques historically has

been used to assess the quality of source rocks,

but now is widely used to help evaluate some unconventional reservoirs

(reservoirs that are both source and productive).

Pathways that

convert living organisms to organic carbon, from "Bitumens,

Asphalts, and Tar Sands" by

George V.

Chilingar,

Teh Fu Yen, 1978. Pathways that

convert living organisms to organic carbon, from "Bitumens,

Asphalts, and Tar Sands" by

George V.

Chilingar,

Teh Fu Yen, 1978.

In the lab, it is relatively easy to distinguish kerogen from hydrocarbons:

kerogen is insoluble in organic solvents, oil and bitumen are

soluble. Pyrobitumen is not soluble but its hardness is used to

identify it from kerogen.

Graphite is evident on resistivity logs because of the very

low resistivity; all other forms of organic carbon are resistive.

Organic

carbon has a density near that of water, so it looks like porosity

to conventional porosity logs. High resistivity with some apparent porosity on a log

analysis is a good indicator of organic carbon content OR

ordinary hydrocarbons OR both.

TYPES OF KEROGEN

TYPES OF KEROGEN

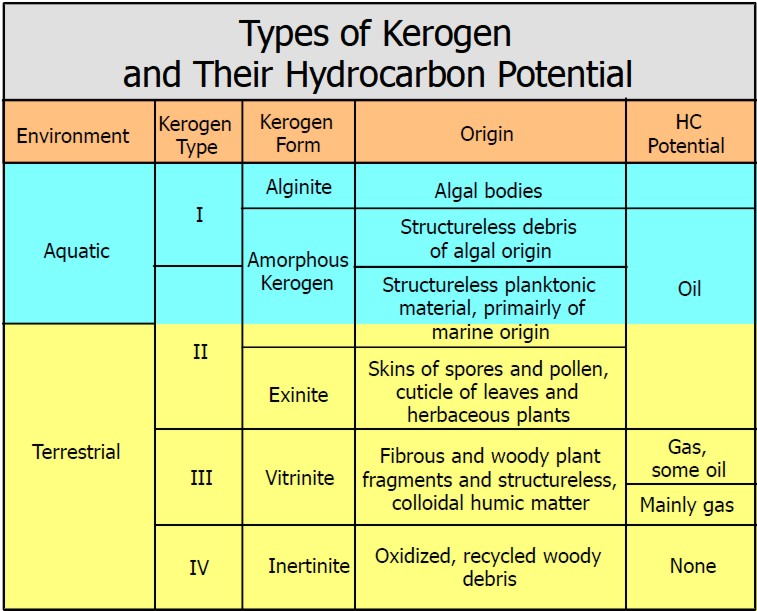

Organic

material can be classified according to the source of

the material, as shown below.

Origin, type, source, and

hydrocarbon potential of different kerogens.

Organic content in gas shales is usually Type II,

as opposed to coals, which contain mostly Type III

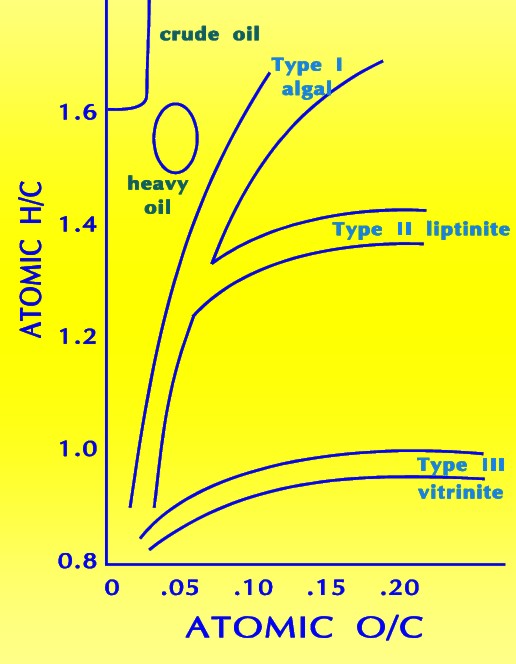

The

most commonly utilized scheme for classifying organic matter in

sediments is based on the relative abundance of elemental carbon,

oxygen, and hydrogen plotted graphically as the H/C and O/C ratio on

a so called Van Krevelen diagram. The

most commonly utilized scheme for classifying organic matter in

sediments is based on the relative abundance of elemental carbon,

oxygen, and hydrogen plotted graphically as the H/C and O/C ratio on

a so called Van Krevelen diagram.

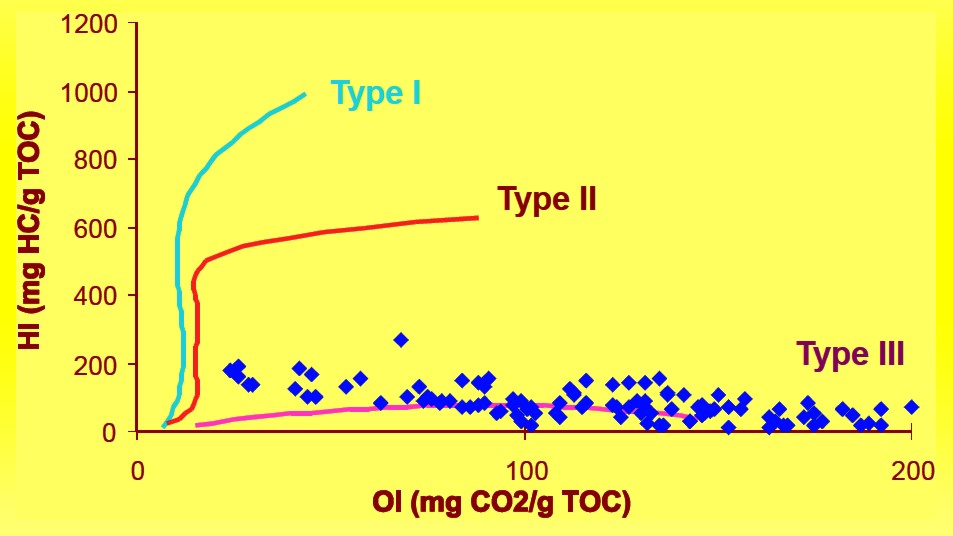

The classic Van Krevelen diagram

Rather than plot the elemental ratios it is common to plot indices

determined by a pyrolysis technique referred to as Rock Eval. In the

pyrolysis techniques two indices are determined: the Hydrogen Index

(HI) which is milligrams of pyrolyzable hydrocarbons divided by TOC

and the Oxygen Index (OI) which is milligrams of pyrolyzable organic

carbon dioxide divided by TOC.

Cross-plots of both elemental H/C and O/C ratios or of HI and OI are

utilized to discriminate four ‘fields’ which are referred to as

Types I, II, III, and IV kerogen.

Type I kerogen is hydrogen rich (atomic H/C of 1.4 to 1.6: HI of >

700) and is derived predominantly from zooplankton, phytoplankton,

micro-organisms (mainly bacteria) and lipid rich components of

higher plants (H/C ratio 1.7 to 1.9).

Type II kerogen is intermediate in composition (H/C ≈ 1.2: HI ≈ 600)

and derived from mixtures of highly degraded and partly oxidized

remnants of higher plants or marine phytoplankton.

Type III kerogen is hydrogen poor (H/C ratio 1.3 to 1.5) and oxygen

rich and is mainly derived from cellulose and lignin derived from

higher plants.

Type IV kerogen is hydrogen poor and oxygen rich and essentially

inert. This organic matter is mainly derived from charcoal and

fungal bodies. Type IV kerogen is not always distinguished but is

grouped with Type III.

The different types of organic matter are of fundamental importance

since the relative abundance of hydrogen, carbon, and oxygen

determines what products can be generated from the organic matter

upon diagenesis. Since coal is comprised predominantly of Type III

kerogen, there is little liquid hydrogen generating capacity. If the

coal includes abundant hydrogen rich components (such as spores,

pollen, resin, waxes - Type I or II), it will generate some liquid

hydrocarbons. Although not common, some oil deposits are thought to

be sourced by coals.

Note: Portions of the above

Section, and the next Section, were taken verbatim (with moderate

editing) from CBM Solutions reports.

Analyzing TOC IN THE LABORATORY

Analyzing TOC IN THE LABORATORY

The total

organic carbon content of rocks is obtained by heating the

rock in a furnace and combusting the organic matter to

carbon dioxide. The amount of carbon dioxide liberated is

proportional to the amount of carbon liberated in the

furnace, which in turn is related to the carbon content of

the rock. The carbon dioxide liberated can be measured

several different ways. The most common methods use a

thermal conductivity detector or infrared spectroscopy.

Many source rocks also include inorganic sources of carbon

such as carbonates and most notably calcite, dolomite, and

siderite. These minerals break down at high temperature,

generating carbon dioxide and thus their presence must be

corrected in order to determine the organic carbon content.

Generally, the amount of carbonate is determined by acid

digestion (normally 50% HCl) and the carbon dioxide

generated is measured and then subtracted from the total

carbon dioxide to obtain the organic fraction.

Total organic

carbon is often taken to mean the same thing as kerogen, but this is

not the case. Kerogen is made up of oxygen, nitrogen, sulphur, and

hydrogen, in addition to carbon. The standard pyrolysis lab

procedure measures only the carbon, so total organic carbon excludes

the other elements.

About 80% of a typical kerogen (by weight) is carbon, so the weight

fraction of TOC is 80% of the kerogen weight. The factor is

lower for less mature and higher for more mature kerogen:

1: Wtoc = Wker * KTOC

OR 2: Wker = Wtoc / KTOC

Where:

Wtoc = weight fraction of organic carbon

Wker = weight fraction of kerogen

KTOC = kerogen correction factor - range = 0.68 to 0.90, default 0.80

Another

lab procedure, called RockEval, burns both hydrogen and carbon, so

the data needs to be calibrated to the standard method by performing

a chemical analysis on the kerogen. Typically the organic carbon

needs to be reduced by about 10% (the weight of the hydrogen burned)

to match the standard method.

Rock Eval is the trade name for a set of equipment used in the lab

to measure organic content of rocks, as well as other properties of

the organics that help to identify the kerogen type. Rock-Eval combusts

a crushed sample of rock at 600ºC. Refractory organic matter

such as inertinite does not combust readily at 600ºC so most coal

samples yield Rock-Eval measured TOC values much lower than actual

values because of incomplete combustion. Rock-Eval is not

recommended for use with coals or source rocks with significant

amounts of Type III and IV kerogen.

A rock sample is crushed finely enough so that 85% falls through a

75 mesh screen. Approximately 100 mg of sample is loaded into a

stainless steel crucible capped with a micro mesh filter. To ensure

accuracy, standard samples are loaded at the beginning and end of

the run. Any drift in data can be detected and the samples rerun if

necessary.

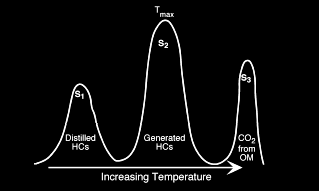

The analyzer consists of a flame ionization detector and two IR

detector cells. The free hydrocarbons (S1) are determined from an

isothermal heating of the sample at 340 degrees Celsius. These

hydrocarbons are measured by the flame ionization detector. The

temperature is then increased from 340 to 640 degrees Celsius.

Hydrocarbons are then released from the kerogen and measured by the

flame ionization detector creating the S2 peak. The temperature at

which S2 reaches its maximum rate of hydrocarbon generation is

referred to as Tmax. The CO2 generated from the oxidation step in

the 340 to 580 degrees Celsius is measured by the IR cells and is

referred to the S3 peak.

Measured results from a typical Rock Eval study will contain: Measured results from a typical Rock Eval study will contain:

TOC% - Weight percentage of organic carbon

S1 = amount of free hydrocarbons in sample (mg/g)

S2 = amount of hydrocarbons generated through thermal

cracking (mg/g) –

provides the quantity of

hydrocarbons that the

rock has the potential to

produce through diagenesis.

S3 = amount of CO2 (mg of CO2/g of rock) - reflects the amount of oxygen

in the oxidation step.

Ro = vitrinite reflectance (%)

Tmax = the temperature at which maximum rate of

generation

of hydrocarbons occurs.

Calculated results include:

Hydrogen index

1: HI = 100 * S2 / TOC%

Oxygen index

2: OI = 100 * S3 / TOC%

Production index

3: PI = S1 / (S1 + S2)

|

Depth (m) |

TOC |

SRA |

Tmax |

Meas. |

HI |

OI |

S2/S3 |

S1/TOC*100 |

PI |

|

Top |

S1 |

S2 |

S3 |

(°C) |

% Ro |

|

X025 |

1.35 |

0.05 |

1.72 |

0.63 |

444 |

|

128 |

47 |

3 |

4 |

0.03 |

|

X040 |

1.18 |

0.05 |

1.65 |

0.57 |

443 |

|

140 |

49 |

3 |

4 |

0.03 |

|

X050 |

0.83 |

0.03 |

1.31 |

0.55 |

443 |

|

158 |

66 |

2 |

4 |

0.02 |

|

X065 |

0.80 |

0.04 |

1.00 |

0.58 |

440 |

|

126 |

73 |

2 |

5 |

0.04 |

|

X075 |

0.75 |

0.05 |

1.04 |

0.72 |

438 |

|

138 |

96 |

1 |

7 |

0.05 |

|

X090 |

1.04 |

0.09 |

2.52 |

0.29 |

452 |

|

241 |

28 |

9 |

9 |

0.03 |

|

X110 |

1.02 |

0.05 |

1.16 |

0.56 |

441 |

|

114 |

55 |

2 |

5 |

0.04 |

|

X135 |

1.05 |

0.05 |

1.32 |

0.57 |

443 |

|

125 |

54 |

2 |

5 |

0.04 |

Laboratory measured TOC values (weight %) with measured and

computed indices

HI versus OI plot example, indicating Type III kerogen

An alternate

method for measuring TOC by solution rather than pyrolysis is

described below, from a 1980's TOC report from Australia.

"The samples are

analyzed for total organic carbon (TOC) according to AS 1038 Part 6.

Moisture determinations are made to permit conversion to a dry

basis. Carbon occurring as carbonate ion is determined to correct

the gross carbon data to give the organic carbon content. This is

done by driving off carbonate minerals with HCl acid.

The crushed and sieved (100 mesh) samples are weighed and

exhaustively extracted in a Soxhlet apparatus using a

benzene-methanol mixture. After removal of methanol by azeotropic

distillation with benzene, the residue in benzene is diluted with

hexane and the hydrocarbon solution separated by filtration from the

brown precipitate. The latter is then dissolved in methanol. The

yield of methanol soluble material is determined gravimetrically.

The hexane soluble portion of the extractable organic matter

(E.O.M.) is weighed and chromatographed on silica. Elution with

hexane gives predominantly alkanes and subsequent elution with

hexane/benzene yields mainly monocyclic and polycycllc aromatic

hydrocarbons. The eluted hydrocarbons are weighed, and then analyzed

by gas chromatography / mass spectrometry."

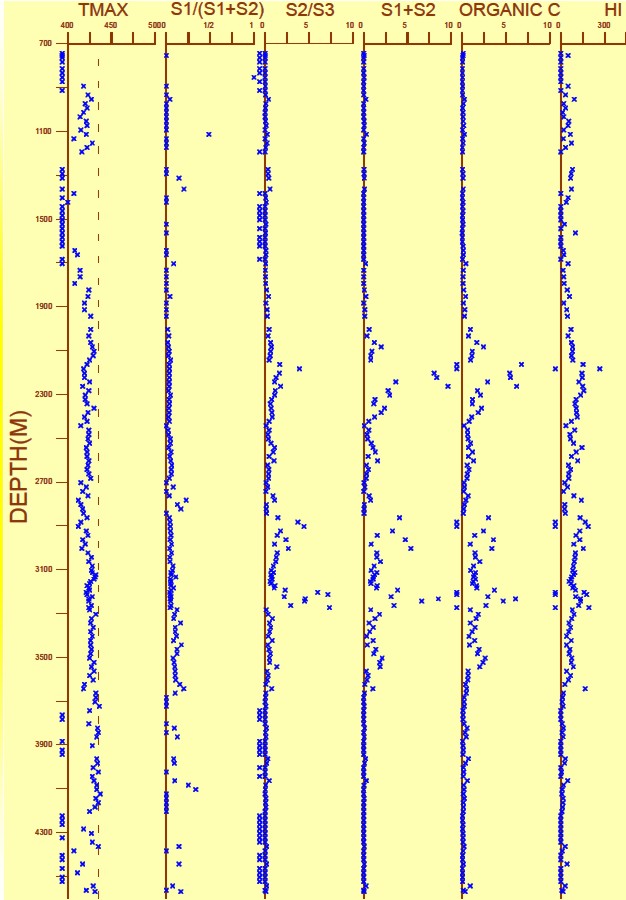

Geochemical Logs

Geochemical Logs

Measured and calculated indices can be plotted versus depth; the

resulting log

is called a Geochemical Log.

A geochemical log from offshore

East Coast Canada

KEROGEN maturity

KEROGEN maturity

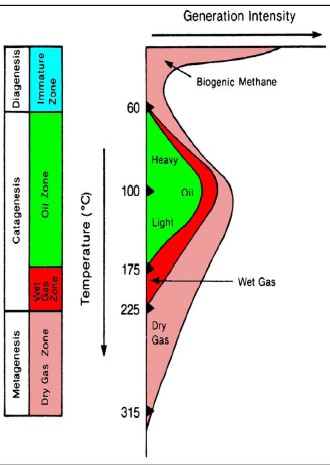

The

hydrocarbon potential of organic carbon depends on the thermal

history of the rocks containing the kerogen. Both temperature and

the time at that temperature determine the outcome. Medium

temperatures

(< 175 C) produce mostly oil and a little gas. Warmer temperatures

produce mostly gas. The

hydrocarbon potential of organic carbon depends on the thermal

history of the rocks containing the kerogen. Both temperature and

the time at that temperature determine the outcome. Medium

temperatures

(< 175 C) produce mostly oil and a little gas. Warmer temperatures

produce mostly gas.

Hydrocarbon

type versus temperature

defines "oil window" and "gas window",

with some obvious overlap

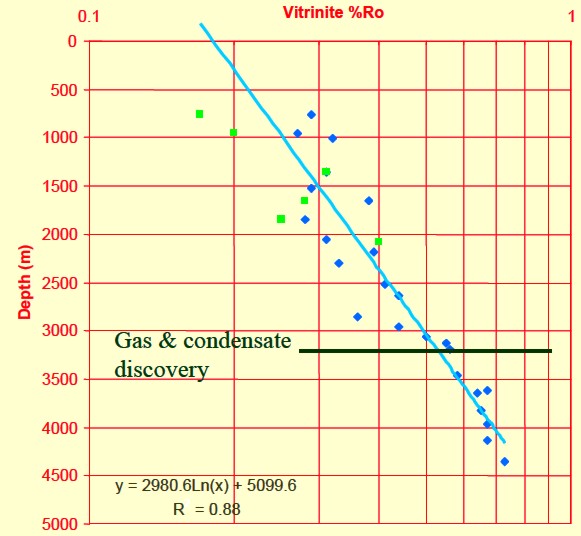

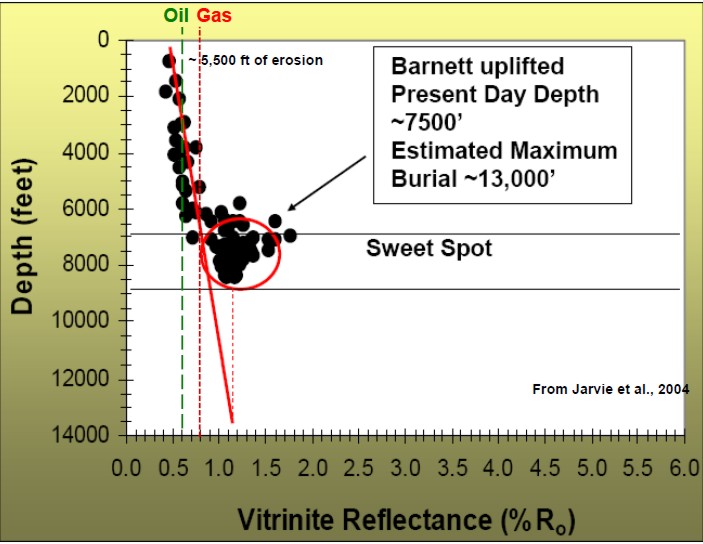

Vitrinite reflectance (Ro) is used as an indicator of the level of

organic maturity (LOM). Ro values between 0.60 and 0.78 usually

represent oil prone intervals. Ro > 0.78 usually indicates gas

prone. High values can suggest "sweet spots" for completing gas

shale wells.

Measurement of vitrinite reflectance was

described as follows from the 1980's TOC report.

"Sample

chips or sidewall core samples are cleaned to remove drilling mud or

mud cake and then crushed using a mortar and pestle to a grain-size

of less than 3 mm. Samples are mounted in cold-setting resin and

polished ''as received", so that whole-rock samples rather than

concentrates of organic matter are examined. This method is

preferred to the use of demineralized concentrates because of the

greater ease of identifying first generation vitrinite and, for

cuttings samples, of recognizing cavings. The core samples are

mounted and sectioned perpendicular to the bedd1ng.

Vitrinite reflectance measurements are made using immersion oil of

refractive index 1.518 at 546 nm and 23°C and spinel and garnet

standards of 0.42%, 0.917% and 1.726% reflectance for calibration.

Fluorescence-mode observations are made on all samples and provide

supplementary evidence concerning organic matter type, and exinite

abundance and maturity. For fluorescence-mode a 3 mm BG-3

excitation filter is used with a TK400 dichroic mirror and a K490

barrier filter."

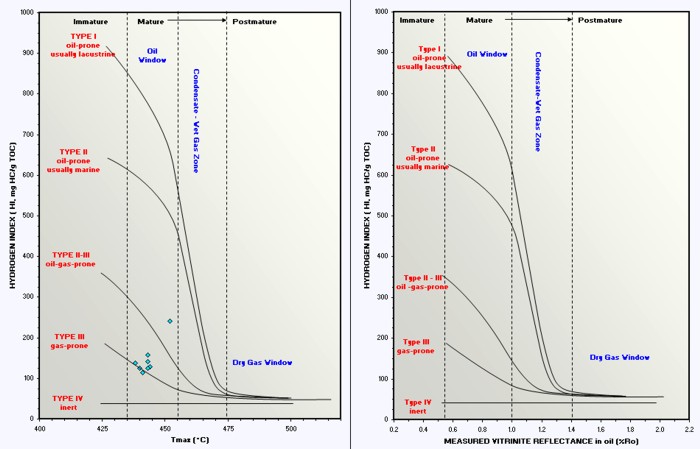

Tmax is also a useful indicator of

maturity, higher values being more mature.

Graphs of HI vs Ro and HI vs Tmax are

used to help refine kerogen type and to assess maturity with respect

to the oil and gas "windows". Depth plots of Ro and Tmax are helpful

in spotting the top of the oil or gas window in specific wells, and

in locating sweet spots for possible production using horizontal

wells.

Crossplots of HI vs Tmax and HI vs Ro

determine organic maturity, kerogen type, and whether the rock is in

the oil or gas window. Immature and post mature rocks are not overly

interesting as possible source or reservoir rocks.

Depth plot of Ro to determine trend line and location of oil and gas

windows (Ro > 0.55).

Ro is plotted on a logarithmic scale, which makes the trend line

relatively straight.

Thermal maturity as indicated by

vitrinite reflectance (Ro) versus depth for a Barnett shale, showing

"sweet spot" and

oil versus gas “windows”.

|