|

Calculating Net Pay with

Cutoffs

Calculating Net Pay with

Cutoffs

"Net Pay" is

defined as the thickness of rock that contributes to

economically viable production with today's technology,

today's prices, and today's costs. Net pay is obviously a

moving target since technology, prices, and costs vary

almost daily. Tight reservoirs or shaly zones that were

bypassed in the past are now prospective pay zones due to

new technology and continued demand for hydrocarbons.

We determine net pay by applying appropriate cutoffs to

reservoir properties so that unproductive or uneconomic

layers are not counted. This can be done with both log and

core data.

Routine, or

conventional, core analysis data can be summed and averaged to

obtain mappable reservoir properties, just like log analysis

results. These mappable properties are also used to compare log

analysis results to core data. If the mappable properties do not

match over the same rock interval, some adjustments must be made to

the log analysis. Be sure to depth match the core to the logs first,

and take into account macro and micro fractures that the logs cannot

see. Laminated reservoirs may cause point by point differences but

the average values of log and core properties should be similar.

Cumulative reservoir properties, after appropriate cut offs are

applied, provide information about the pore volume (PV), hydrocarbon

pore volume (HPV), and flow capacity (KH) of a potential pay zone.

These values are used to calculate hydrocarbon in place, recoverable

reserves, and productivity of wells. The following algorithm is

a highly simplified one pass approach, which would need considerable

adjustment to run on a real computer. However it is suitable for

discussion purposes.

Pay Flag Calculation

- Simple Model

Pay Flag Calculation

- Simple Model

It is normal to apply cutoffs to each calculated

result to eliminate poor quality or unproductive zones. Cutoffs

are usually applied to shale volume, porosity, water saturation,

and permeability. The layer is not counted as “pay” if it fails

any one of the four cutoffs.

Typical cutoffs are:

1: IF (Vsh <= VSHmax)

* (PHIe >= PHImin) * (Sw <= SWmax) * (Perm >= PERMmin)

= 1

2: THEN PAYFLAG = 1

3: ELSE PAYFLAG = 0

4: Hnet = SUM (PAYFLAG * INCR)

Where:

Hnet = Net Pay

INCR = digitizing increment

Perm = permeability (md)

PERMmin = permeability cutoff (md)

PHImin = porosity cutoff (fractional)

PHIe = effective porosity (fractional)

Sw = water saturation (fractional)

SWmax = saturation cutoff (fractional)

Vsh = volume of shale (fractional)

VSHmax = shale volume cutoff (fractional)

Typically:

VSHmax =

0.25 to 0.45

PHImin = 0.03

to 0.16

SWmax = 0.30

to 0.70

PERMmin = 0.01

to 5.0 mD

These values must be appropriate for the

rock sequence. Values in unconventional reservoirs may be more

extreme.

In

reservoir simulation work, the Net Reservoir is also needed. In

this case, set SWmax = 1.00. The result of equations 1 to 4 for

this case is Hres instead of Hnet.

To map Net Sand, set PHImin = 0.0

and SWmax = 1.0. The result of equations 1 to 4 for this case is

Hsnd instead of Hnet.

Some

people are interested in "Net to Gross Ratio" but they have to be

specific as to whether they mean:

5: Gross = ZONE_BOTTOM - ZONE_TOP

6: NetPayToGross = Hnet / Gross

7: NetResToGross = Hres / Gross

8: NetSndToGross = Hsnd / Gross

COMMENTS:

The pay flag may be very sensitive to small changes in cutoffs.

Any one of the four primary cutoffs can create a "FAIL"

situation. This is enough to fail the layer even if other cutoffs

do not fail the zone. The

Some

cutoffs may be set high enough or low enough so as not to be effective.

For example, if PERMmin = 0, then no value of Perm could be less

than PERMmin, so permeability could not fail to pass a layer.

More

than one set of cutoffs are normally run and the results compared

to find the set that appears to give reasonable results when compared

to production profiles in the area.

Since porosity is somewhat proportional to shale

volume, saturation somewhat proportional to porosity, and

permeability somewhat proportional to all three, it is desirable

to choose a balanced set of cutoffs. Balanced cutoffs in a

hydrocarbon bearing zone usually will fail a layer with more

than one cutoff. If only one cutoff fails a layer, the cutoffs

may need some adjustment.

Cutoffs can be tested against production

flowmeter data and can be tuned, in some cases, based on actual

production rates

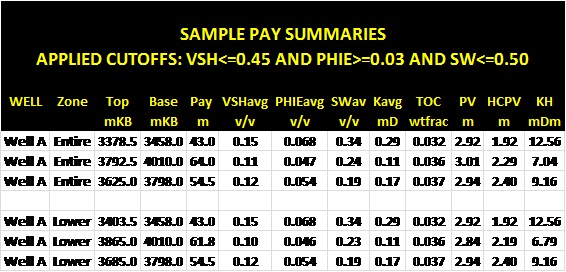

Sample net pay table with average

and cumulative mapable properties based on a typical set of cutoffs

appropriate for a low porosity tight gas interval.

Pay Flag Calculation

- Descriptive Model

Pay Flag Calculation

- Descriptive Model

Each

layer is tested against a series of cutoffs to determine if the

layer can contribute to production from the well. Each test must

be run in the order shown below so that the correct description of

the layer can obtained:

1: IF PHIe < PHImim THEN PAYFLAG$ = "TIGHT"

2: OR IF Sw > SWmax THEN PAYFLAG$ = "WET"

3: OR IF Perm < PERMmin THEN PAYFLAG$ = "LOWPERM"

4: OR IF Vsh > VSHmax THEN PAYFLAG$ = "SHALY"

5: OTHERWISE PAYFLAG$ = "PAYZONE"

6: IF PHIdc >= PHInc + TOLER THEN PRODFLAG$ = "GAS"

6: IF PHIdc < PHInc + TOLER THEN PRODFLAG$ = "OIL"

7: IF PHIe * Sw > PHIxSWmax THEN PRODFLAG$ = "H2O"

8: Hnet = SUM (PAYFLAG$ = "PAYZONE" * INCR)

Sonic neutron crossover can also be used to test for "GAS"

flag.

Where:

Hnet = sum of layer thicknesses which passed all cutoffs (ft or

m)

Perm = permeability (md)

PERMmin = permeability cutoff (md)

PHImin = porosity cutoff (fractional)

PHIe = effective porosity (fractional)

PHIdc = shale corrected density log porosity (fractional)

PHInc = shale corrected neutron log porosity (fractional)

PHIxSWmax = porosity saturation product cutoff (fractional)

Sw = water saturation (fractional)

SWmax = saturation cutoff (fractional)

TOLER = crossover tolerance for "GAS" flag (fractional)

Vsh = volume of shale (fractional)

VSHmax = shale volume cutoff (fractional)

RECOMMENDED

PARAMETERS:

RECOMMENDED

PARAMETERS:

1. High porosity set:

PHImax SWmax PERMmin VSHmin PHIxSW

0.00 1.0 0.0

0.0 1.00

0.15 0.5 5.0 0.3 0.07

0.20 0.4 10.0 0.3 0.07

0.25 0.3 15.0 0.3 0.07

2.

Low porosity set:

PHImax SWmax PERMmin VSHmin PHIxSW

0.00 1.0 0.0

0.0 1.00

0.01 0.90 0.005 0.7 0.10

0.03 0.85

0.01

0.6 0.09

0.05 0.80 0.05 0.5 0.08

0.07 0.70 0.10 0.4 0.07

0.09 0.50 0.50 0.4 0.06

0.12 0.40 1.00 0.4 0.05

Selecting Cutoffs

Selecting Cutoffs

The

only real way to determine cutoffs is to run a flowmeter in the

well over the reservoir. If an interval flows oil or gas, it is

above cutoffs - if it doesn't flow oil or gas, it's below cutoffs.

If it flows water with oil or gas, it has failed the water saturation

cutoff. This procedure requires that you perforate poor quality

rock to see if it will flow. Some managers will resist this added

expense as they "know" what produces and what doesn't.

Close

spaced DST's can also be used in open or cased hole to simulate

a flowmeter profile.

You

can mimic this in the lab with flow tests in core plugs using

reservoir fluids under simulated formation pressure and temperature.

However, hardly anyone actually does either flowmeter or core

flow analysis because it is expensive and often means completing

or coring poor quality rock to find out how low the cutoffs can

be set.

The

pragmatic approach is much more widely used.

1.

Plot core porosity vs logarithm of core permeability. Fit a semi-log

line through the data points (exclude fractured plugs). For gas

use a perm cutoff of 0.1 to 1.0 md, for oil use 1.0 to 5.0 md.

Find the equivalent porosity on this graph corresponding to the

selected perm cutoff. This is your porosity cutoff.

2.

Plot porosity vs water saturation in the oil or gas leg above

the transition zone. This can be log analysis data or values from

capillary pressure curves. Fit a hyperbolic line through the data.

Enter with porosity cutoff and find corresponding SW. This is

the SW cutoff.

3.

In shaly sands, plot porosity vs shale volume. Enter graph with

porosity cutoff and pick corresponding shale volume. This is Vsh

cutoff.

This

is called a coordinated cutoff set.

Reservoir

engineers sometimes plot cumulative porosity or permeability or

both (sort data into ascending order first). They then place the

cutoff at the 5 or 10% accumulation. This is exceedingly arbitrary

but was a widespread method. It was only vaguely useful if the

core contained no poor quality rock or if there was no spread

in the rock properties.

Net Pay Continuity Calculation Net Pay Continuity Calculation

In

some situations, the continuity of the pay zone is important to

exonomic decisions. Tar sand mining, steam assisted gravity

drainage, fire floods, and some water flood scenarios need

continuous reservoir quality rock to be effective. Thin non-pay

intervals are OK, but thick ones are not.

Net Pay Continuity Calculation

Net Pay Continuity Calculation

The

levels that pass these four tests can be checked for continuity

against two thickness criteria. One is the minimum zone thickness

needed to be considered as a pay zone. The second is a maximum

non-pay interval allowed in the overall pay zone before the zone

is broken into more than one pay zone. These two criteria are

called the acceptance thickness and rejection thickness respectively.

To

find the beginning of a possible pay zone, search from the top

of the computed interval for the first data set with a "pass"

in its cutoff field.

Then

find the first deeper level with a "fail" in its cutoff

field. The depths of these two points define the top (ZONETOP)

and bottom (ZONEBOTTOM) of a zone. This interval thickness is

tested against the acceptance criteria.

The

depth of the next pay zone top is then found and the interval

between pay zones tested against the rejection criteria.

1:

IF PAYFLAG$ ="OIL"

2: OR IF PAYFLAG$ ="GAS"

3: OR IF PAYFLAG$ ="H2O"

4: THEN CUTOFF$ = "PASS"

5: OTHERWISE CUTOFF$ = "FAIL"

6: IF CUTOFF$ = "PASS"

7: AND TOPFLAG$ = "START"

8: THEN ZONETOP = Depth

9: AND TOPFLAG$ = "TOPFOUND"

10: AND BOTTOMFLAG$ = "START"

11: IF CUTOFF$ = "FAIL"

12: AND BOTTOMFLAG$ = "START"

13: THEN ZONEBOTTOM = Depth

14: AND BOTTOMFLAG$ = "BOTTOMFOUND"

15: AND TOPFLAG$ = "START"

16: AND NEXTTOPFLAG$ = "START"

17: IF CUTOFF$ = "PASS"

18: AND NEXTTOPFLAG$ = "START"

19: THEN NEXTTOP = Depth

20: AND NEXTTOPFLAG$ = "TOPFOUND"

21: IF ZONEBOTTOM - ZONETOP > HACCEPT

22: THEN FOR Depth = ZONETOP

23: TO Depth = ZONEBOTTOM

24: PAYFLAG$ = "PAY"

25: OTHERWISE PAYFLAG$ = "BARREN"

26: END LOOP 2

27: IF NEXTTOP - ZONEBOTTOM < HREJECT

28: THEN FOR Depth = ZONEBOTTOM

29: TO Depth = NEXTTOP

30: PAYFLAG$ = "PAY"

31: OTHERWISE PAYFLAG$ = "BARREN"

32: END LOOP 3

33; END LOOP 1

Repeat

these steps until the bottom of the computation interval is reached.

At

this time each level computed will have two flags set - one to

indicate whether it passed cutoffs (CUTOFF$) and whether the layer

is considered part of a pay zone (PAYFLAG$), even if it failed

its cutoffs. To find net pay thickness, count the number of levels

with the pay flag equal to "pay" and multiply by the

depth increment between the data points.

32:

Hnet = Sum ((IF PAYFLAG$ = "PAY") * THICKi)

33: Hgross = ZONETOP - ZONEBOTTOM

34: NETratio = Hnet / Hgross

Where:

Depth = current depth (ft or m)

HACCEPT = minimum pay zone thickness cutoff (ft or m)

Hgross = gross interval (ft or m)

Hnet = sum of layer thicknesses which passed all cutoffs (ft or

m)

HREJECT = maximum reject zone thickness cutoff (ft or m)

NETratio = ratio of net to gross pay (fractional)

NEXTTOP = top depth of next pay zone (ft or m)

THICKi = individual layer thickness (ft or m)

ZONEBOT = bottom of computation interval (ft or m)

ZONETOP = top of computation interval (ft or m)

COMMENTS:

Some analysts prefer not to count layers which failed cutoffs

but are included in net interval because they are too thin to

be rejected. To accomplish this, change Step 39 to read:

39:

Hnet = Sum ((IF PAYFLAG$ = "PAY" AND IF CUTOFF$ = "PASS")

* THICKi)

NUMERICAL

EXAMPLE

NUMERICAL

EXAMPLE

Assume data as shown

below. Note that data listing is

in percent, not fractional, units.

Data for net pay example

1.

If cutoffs are:

PHIcut = 3.0 (%)

VSHcut = 40.0 (%)

PERMcut = 0.0 (md)

SWcut = 90.0 (%)

PHIxSWcut = 1.0

HACCEPT = 1.0 (m)

HREJECT = 0.0 (m)

Then

net pay extends from 2054.1 to include 2063.1.

2.

If SWcut is lowered to 50.0, then net pay covers 2054.1 to 2059.5

and 2061.9 to 2062.2 in two zones.

3.

If HREJECT = 3 m, then these two pay zones combine to form one

zone because the rejected interval is less than 3.0 m.

4.

If HACCEPT = 3.0 m, then the second zone is not pay because it

is not thick enough.

Rejected

intervals are included in the zone for Case 3 and contribute to

net pay thickness.

|