|

STEP

1: Define Petrophysical Objectives

STEP

1: Define Petrophysical Objectives

We seldom do petrophysical analysis for its own sake – usually

the results are used as input to some other activity, like a well

completion plan, an economic analysis, or a reservoir description

for a full field simulation study. An organized approach to

managing petrophysical projects is mandatory. Here is Crain's

time-tested procedure.

Clearly

defined petrophysical goals and procedures help assure an efficient,

technically sound result. The primary purpose is to give the petrophysical

team a set of step by step instructions to assist them in project

definition, planning, execution, and quality control. This will

help to reduce errors and duplication of effort, and maximize

project quality. A good plan and procedure keeps expectations

in line with the data type and quality, as well as with budget

and time constraints.

The

petrophysical plan also helps to acquaint management, the client,

and other groups who rely on the petrophysical results, with our

methods and data requirements. Since integration of petrophysical

data with larger projects is one of the important goals, guidelines

on how to handle these relationships are described here.

Petrophysics

is often a step by step procedural process. However, a number

of motherhood statements are understood to be included (eg. thoroughness,

diligence, persistence, quality, resources). Although we all know

that these factors are important, most unhappy clients, blown

budgets, and delayed deadlines are caused by forgetting these

basics.

The

role of project managers and senior managers is also an important

aspect of an integrated project, since their support is crucial

to the success of a project. Inadequate or late disposition of

resources can only be corrected by senior management, no matter

how willing the analytical staff may be.

The

objective of the Petrophysical Phase is to provide an independent

analysis of all producing or prospective reservoir zones seen

in well logs. The project usually requires integration of the

well log analysis with geological, stratigraphic, petrographic,

conventional core, special core, completion, production, and reservoir

engineering data.

Petrophysical Cross Section From a Forensic Log

Analysis –

Guess Where the Horizontal Well Was Drilled!

STEP

2: Define Who Does What

STEP

2: Define Who Does What

The petrophysical phase of a project is usually a small to medium

sized portion of a larger project. The usual project phases are:

1.

Geophysical Phase

2. Geological Phase

3. Petrophysical Phase

4. Reservoir Engineering Phase

5. Reservoir Simulation Phase

6. Facilities and Economics Phase

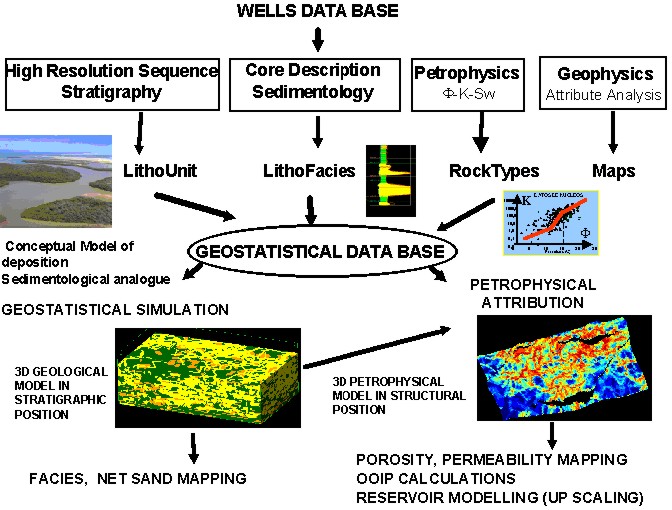

Where petrophysics fits in the

scheme of reservoir description (courtesy of GeoNeurale)

Although

the phases appear to be sequential, there is considerable overlap

and feedback between phases. Careful planning of all phases, and

special attention to the inter-relationships between phases, will

provide the optimum results and minimize costs.

For

example, all Phases require log data, but of different types,

intervals, scales, accuracy, and at different times in the life

of the project. A decision has to be made as to who does the digitizing,

who checks it, and is it done once for all to use, or done as

needed by each group?

Similarly,

Petrophysics requires core porosity vs permeability transforms

and capillary pressure water saturation vs porosity relationships

at an early stage; reservoir engineering needs this data much

later. Should reservoir engineers provide this data to the log

analysts, or vice versa?

The

same questions must be answered with respect to petrographic data,

fluid properties and contacts, geological structure, and other

reservoir description data. All of this data is required by more

than one of the Phases, but at different times.

Once

decisions are made as to who does what, the project manager, and

phase managers, must follow up to be sure the various tasks are

being accomplished correctly and on time, and what other resources

might be needed to help finish.

STEP

3: Plan the Project Integration

STEP

3: Plan the Project Integration

Integrated planning will coordinate the tasks of all phases of

the project. Critical path timing can be displayed on PERT charts,

as below, or a simple whiteboard, or a spreadsheet such as Excel or

Lotus 1-2-3. The three illustrations below are from an article in

AAPG Geobyte Magazine (199?) by Robert Elphick, my good friend

and long-time editor of Geobyte.

PERT Chart for Petrophysical Project

Better

definition of resource needs and resource conflicts can be seen

on Gantt charts.

GANTT Chart for Petrophysical Project

Problems show up even more clearly on a Resource Gantt chart.

Resource GANTT Chart for Petrophysical Project

Although

easy to make, these charts require constant updating, usually

weekly. However, the effort is rewarded by catching resource deficiencies

or conflicts before they proceed too far. The three illustrations

shown above are from an article by my good friend Robert Elphick,

published in SPWLA Log Analyst, Dec 1992.

Additional

entries on the Resource Gantt chart are helpful. For example,

showing the timing of all inputs (source data) and outputs (deliverables)

for a resource will show up conflicts that are not apparent in

the resource allocation bars. The output of one Phase is often

the input to another Phase. Assigning people to a Phase when their

inputs are not available produces nothing but frustration.

While

resources may need re-allocation to overcome some obstacles, this

may incur some penalty due to broken continuity or loss of man-power.

Adding people to a team has diminishing returns, which set in

when a team exceeds 6 or 7 people. Conversely, adding or speeding

up hardware and software usually has immediate, low-cost benefits,

provided of course that these resources are truly tested and ready

for release in a real-world environment.

Regular

meetings of all Phase leaders are needed to keep the various activities

coordinated. These should be short, have an agenda distributed

in advance, and be adjourned promptly when the agenda is exhausted.

Smaller meetings may follow to correct specific problems, but

not all Phase leaders need to be present. If a Phase has a number

of staff, Phase meetings may be needed to assemble progress data

before the formal weekly meetings. Brief written weekly and monthly

progress reports should be distributed to Phase leaders and the

client.

STEP

4: Define the Petrophysical Deliverables

STEP

4: Define the Petrophysical Deliverables

The petrophysical team assists in data gathering, to ensure that

all required data is available at an early stage in the project.

Open

hole logs will be used to determine shale volume, effective porosity,

water saturation, permeability, and (where possible) lithology.

Cased hole log analysis will be performed, as needed, to assist

in determining production characteristics, fluid movements, and

dated fluid contacts. Swept zones, sweep efficiency, and residual

oil saturation in partially depleted reservoirs can often be determined

from modern open and cased hole logs.

Results

will consist of summary tables of pore volume, hydrocarbon pore

volume, flow capacity, average porosity, average water saturation,

average permeability, and net pay after application of cutoffs

and layer depth criteria.

These

results will be used to generate reservoir property maps for estimation

of original oil in place and flow capacity. The maps will be supported

by detailed depth plots and listings of all input and computed

data. Results will be used as input to the Reservoir Engineering

and Reservoir Simulation Phases of the project, and also to assist

in final assessment of mapping performed in the Geological Phase.

Reservoir

zonation is often determined in the Geological Phase, in which

formation tops, stratigraphy, facies, structure, and isopach maps

will be prepared for use in the Petrophysical Phase. Mapping of

petrophysical results and determination of volumetric original

oil in place is usually done as part of the Reservoir Engineering

Phase, but may be delegated to the Geological or Petrophysical

Group.

STEP

5: Define the Resources Required

STEP

5: Define the Resources Required

A technically and economically successful petrophysical analysis

of a large number of wells in any project requires appropriate

application of the following resources:

1.

a petrophysical manager/analyst.

2. one or more trained log analysts.

3. one or more trained log technicians.

4. dedicated computer hardware for each analyst and technician,

capable of fast

processing and plotting.

5. computer software capable of fast, error free computation.

6. trained digitizing staff with digitizing tables and software.

7. a client who can gain access to the required data and deliver

it in a timely manner

8. a work environment that keeps the team intact for the duration

of the project, and in close proximity to each other.

9. sufficient time to perform all data gathering, database building,

data quality control, technical research, data processing, result

verification, data presentation, and reporting

10. a detailed plan that shows all the steps required for completion

and quality control of the above tasks.

11. close integration with other Phases of the project to minimize

duplication of effort and maximize quality of results for the

client.

12. a corporate infrastructure that will quickly rectify any deficiencies

in the application of needed resources.

It

is common to see Resources #1, 2, and 3 combined in one human

brain/body. If timing constraints do not interfere, this approach

gives good results.

Digitizing

(Resource #6) is often done better by the log analysis technician

(Resource #3) because he/she has a vested interest in the quality

of the work. Another option is an out-of-house service bureau

whose primary business is digitizing logs. Quality control of

this function is critical, as all Phases of the project depend

on a clean, complete, correct database.

Resources

#11 and #12 are also important concerns and control time and budget

over-runs as much as the individual actions of the Petrophysical

Team.

STEP

6: Define the Data Gathering Process

STEP

6: Define the Data Gathering Process

Petrophysical data gathering is usually done as part of a team

made up of personnel from several Phases, with a qualified log

analyst as a member of the team. Sometimes, data gathering and

inventory is done by a team from only one of the Phases. These

people must be aware of all the data needed for the entire project,

including petrophysics broad needs, not just those of their own

Phase. To minimize effort later, data gathering must be done thoroughly

and inventoried accurately.

If

data is known or suspected to exist, it must be pursued diligently

and persistently until all avenues are exhausted. If required

data is truly not available, the client should be notified of

the consequences immediately, along with a recommendation for

additional work required to overcome the deficiency. For petrophysics,

the missing data is often the electrical properties, petrographics,

mineralogy, water chemistry/salinity, and core porosity-permeability-grain

density data we need to calibrate the log analysis.

The

cooperation of the client in data gathering is critical. Data

that is overlooked or deliberately held back reduces the quality

of the results, to the detriment of the project and everyone involved

in it, including the client representatives. A copy of the data

inventories should be given to the client, with a request to review

and augment the database where possible.

A

complete list of data required for petrophysics is listed below.

Much of the data listed is needed by more than one Phase. However,

each Phase should prepare its own data gathering list, so that

all required data is properly itemized. The combined data gathering

list should be provided to the client before the data gathering

trip to acquaint them with our needs and expedite the gathering

process.

To

obtain optimum results, the petrophysical team requires all pertinent

well data in a timely manner. If some requested data is not available

or arrives late, it may not be possible to calibrate petrophysical

results adequately. In such cases, a discussion of the data deficiencies

will form part of the final report.

Crain’s Data Gathering Checklist

Project

Definition To Be Provided By Client

-

Names and titles of client's key personnel

-

Brief overview of petrophysical requirements and problems

-

List of pools to be analyzed, brief geological description,

brief production history, fluid types, water problems,

special considerations for each pool

-

List of wells, zones, and intervals to be analyzed

-

List of cored intervals, footage recovered, formations

encountered, interval analyzed, special core analysis

intervals, type of special analysis

-

List of logs available and intervals covered

-

List of XY coordinates and KB elevations, with base

map

-

List of log curves and intervals digitized by client

-

List of log curves and intervals to be digitized by

consultant

-

List of wells that require TVD correction

-

List of workovers in each well, with perf intervals,

date, test and IP results

-

List of formation tops in each well

-

Sample well logs and core data from a cored producing

zone

-

If project definition cannot be supplied by the client

we will do this work BEFORE a final proposal and budget

is madeGeology

Data To Be Provided By Client

-

Technical reports and papers on depositional environment,

structural geology, and petrography

-

Geological cross-sections and stratigraphic correlation

chart, formation descriptions

-

Structure map with well locations, faults, fluid contacts

-

Existing porosity, saturation, net pay, permeability,

pore volume, hydrocarbon pore volume, and flow capacity

maps

-

If cross-section and structure map do not exist, they

will be provided by Geological Phase BEFORE Petrophysical

Phase begins.

Petrophysical

Data To Be Provided By Client

-

Sample description (lithology) logs and mud logs

-

Core description

-

Conventional and special core analysis listings

-

Capillary pressure plots and listings

-

Electrical properties plots and listings (Formation

Factor, A, M, N)

-

Formation water chemistry analyses and resistivity

data

-

Formation temperature vs depth data.

-

Well logs - all porosity, lithology, resistivity,

and production logs, paper copies required

-

Deviation surveys or TVD listings

-

All above data on digital tape or disc, as well as

paper, where possible

-

Petrographic, thin section, SEM, and XRD data

-

Previous reports outlining net pay, water saturation,

porosity, net pay cutoffs, etc

-

Any permeability vs porosity transforms previously

used

-

Any A, M, N transforms and RW data previously used

Drilling/Completion/Testing

Data To Be Provided By Client

- Well ticket data

- Legal name and location

- Casing run, depths, type and weight, amount and

type of cement

- Spud and rig release dates

- Formation top names, and depths

- Perforated intervals, type, spacing, and dates

- Cored intervals, type, size, recovery and dates

- Oil analyses, gravity, and GOR

- Gas analyses, composition, and density

- Original and secondary oil/water, gas/oil contacts

- Completion and workover history

- DST tests, intervals, and results

- RFT tests, intervals, and results

- Perf tests, intervals and results

- Deliverability tests, eg: AOF (gas) and IPR (oil)

- Any special drilling problems: blow-outs, lost circulation

zones, stuck in hole, fractures, over pressure

- Treatment and stimulation history

- Production history plots, including monthly oil,

gas, water, and condensate production

- Injected volumes of gas and/or water used for disposal

or enhanced recovery

- List of accepted formation temperatures

|

|

STEP

7: Build a Clean Database

STEP

7: Build a Clean Database

Preparation of the digital log database is usually the responsibility

of the Petrophysical Team. The requirements of other Phases of

the project must be made known at an early stage so that appropriate

curves and intervals are digitized for all potential uses. An

inventory of hardcopy logs, digitized curves, and intervals will

be maintained by Petrophysics.

If

other Phases prepare log digits for their own use, they should

coordinate their efforts with Petrophysics to minimize duplication.

The

digital log database must reside on one computer under the control

of the Petrophysical Team. This database is termed the Master

Petrophysical Database and cannot be removed or modified except

by authorization of the Petrophysical Manager. It will be backed

up on a weekly basis for safety, with a copy held off premises.

The

integrity of the Master Petrophysical Database is a critical function,

and is the responsibility of ALL petrophysical staff. Problems

or deficiencies in data or procedures should be reported immediately

to the Petrophysical Manager.

Copies

of the Master database may be distributed to other computers or

workstations. However, this data becomes the responsibility of

the users on those workstations. At least one copy of the data

should be in read-only files on the workstation so that users

cannot corrupt the files accidentally. Users may copy these files

to their own directories for their own use. If accidents occur,

the data can be revived from the read-only files.

If

a distributed copy is in use, it is the responsibility of the

user to request updates and to report problems to the Petrophysical

Manager. However, users have a responsibility to make every effort

FIRST to confirm and define the problem by comparing their data

with the read-only files and the hardcopy logs.

Log

data quality control will be undertaken by the Petrophysical Team

as the database is being prepared. If problems are identified

to be caused by inadequate in-house digitizing, further training

will be implemented. Service bureau digitizing will be rejected

if errors are not corrected quickly.

STEP

8: Quality Control the Digital

Database

STEP

8: Quality Control the Digital

Database

Quality control will consist of the following procedures:

1.

If data is provided in digital form, load and print catalog of

all known data files and compare to data inventory. If data is

digitized in-house, proceed as detailed below.

2.

Plot raw data from top to bottom at 1:xxx scale.

3.

Inventory curves on data plot and depth interval covered by each

curve.

4.

Compare curves and intervals to inventory of open hole logs, and

itemize missing curves or intervals.

5.

Compare plotted curves to original logs, and list curves and intervals

that need to be re-digitized.

6.

Initiate (re)digitizing requests.

7.

Re-plot and recheck new digits.

8.

Update data

STEP

9: Execute the Petrophysical Plan

STEP

9: Execute the Petrophysical Plan

Petrophysical analysis will proceed on a pool by pool basis. The

method employed for most studies will involve the following steps,

which may vary depending on available data and project objectives.

1.

Gather and inventory available data, review well files, sample

descriptions, drilling history, drill stem and production tests,

completion and production history, and current status of each

well, based on information in the well history files provided

by the client.

2.

Review conventional and special core analysis data and core description

on the cored wells, and enter all data into database. View available

cores and describe fracture patterns and lithology. Initiate and

monitor further core analysis if required.

3.

Prepare core porosity vs core permeability, and vertical vs horizontal

permeability crossplots (by zone by well and by zone all wells)

and determine best fit equations for each zone. Revise transforms

after water saturation data has been calculated and calibrated

to capillary pressure data.

4.

Crossplot porosity vs formation factor and saturation vs resistivity

index from special core data, by zone by well, and by zone all

wells combined. Determine appropriate electrical properties (A, M, and

N) values from available special core studies, from modern EPT/MSFL

logs, and/or from Pickett plots if suitable water zones exist.

5.

Prepare log database and print inventory of available logs by

reading digital data (provided by the client) over required intervals,

digitizing any missing curves or logs according to accepted log

digitizing specifications. CHECK INVENTORY AGAINST HARD COPY LOG

HEADINGS.

The

curve complement will vary with the age of the logs, but will

include deep and shallow resistivity, sonic, neutron, density,

SP, gamma ray, photoelectric, and thermal decay time where available.

Additional curves will be added as needed and where available.

Old style neutron logs will be converted to a porosity scale.

All data will be decimated to 1 foot or 0.3 meter increment.

6.

Plot all raw data and core data vs depth. Compare to original

logs to verify scales, data quality, depth matching, and missing

data. THIS IS AN ABSOLUTELY ESSENTIAL QUALITY CONTROL STEP AND

MUST NOT BE OMITTED.

7.

Prepare initial log analysis and representative crossplots on

cored intervals on key wells with modern log suites to calibrate

porosity and permeability parameters, using the density-neutron-PE

shale corrected complex lithology three mineral model for both

shaly sands and carbonates. Shale volume will be determined from

SP, GR, and density neutron crossplot (some methods are not appropriate

in some zones). Only those crossplots that are necessary for choosing

parameters will be made, but not all will be presented to the

client.

8.

Select appropriate water resistivity and mud filtrate value for

each zone and select appropriate calculation method for original

reservoir and invaded zone water saturation.

9.

Determine effect of conductive non-clay minerals and adjust saturation

accordingly.

10.

Adjust parameters as required and calculate final log analysis

on cored wells, to obtain a good match to core data.

11.

Calculate log analysis on remaining wells with density-neutron-PE

data, but no core data.

12.

When no PE is available, a 2 mineral model will be used. For old

style neutron cases, lithology will be assumed using log analysis

on offset wells or sample description for control.

13.

Calculate log analysis using the shale corrected sonic log model

for wells with core and/or density neutron data, to calibrate

sonic parameters.

14.

Calculate log analysis on remaining wells which have only sonic

log data.

15.

Perform similar steps for wells with density only or neutron only,

calibrating to core or offset density neutron or sonic data.

16.

Demonstrate calibration of log analysis porosity to core porosity

using depth plots, crossplots, and/or regression analysis.

17.

For wells with ancient logs, determine approximate porosity from

porosity mapping of offset wells, to aid in determining net pay

in these wells.

18.

Determine secondary porosity, fracture location and fracture intensity

from all available methods.

19.

After a few of each log suite are analyzed, write preliminary

report and review preliminary results with client, geology team,

engineering team, and compare to geological cross sections and

zoning concepts, as well as reservoir engineering results.

20.

Revise any methods or parameters and analyze remaining wells.

21.

Prepare cross sections to include all wells and compare shale,

porosity, lithology, saturation, permeability, and fluid contacts

from well to well. Check for consistency, geological variations,

data errors, and analysis errors using Quality Control Checklist.

22.

Compare results to geological zoning and run final layer summaries.

23.

Calculate dated water saturation from thermal decay time log where

available, and compare to original water saturation from resistivity

logs.

24.

Determine and justify (if possible) shale, porosity, permeability,

and water saturation cutoffs by comparing log analysis results

to core data, production, and test data.

25.

Determine original and dated gas/oil and oil/water contacts to

define gross intervals, checking with production and test data,

properly adjusted for capillary pressure data and age of well.

26.

Correlate capillary pressure curves and log analysis saturations

over transition zones.

27.

Calculate and print average porosity, average saturation, pore

volume, hydrocarbon pore volume, flow capacity, and productivity

summaries for each layer in each zone for mapping of reservoir

properties.

28.

Prepare depth plots of raw data and answers for wells with any

useable log curves and results at scales of 1:200 and 1:500, for

correlation and mapping purposes, showing formation analysis results,

core analysis porosity and permeability (where available), flags

for bad hole, light hydrocarbons, and pay intervals, and other

requested curves.

29.

Annotate tops, tests, cores, perfs, and fluid contacts on depth

plots. Add annotation tail with this data, parameters used, and

pay zone summaries.

30.

Print detail listings of all requested results for all zones.

31.

Present copies of necessary crossplots for each zone, with discussion

and explanation.

32.

Write final report, documenting calculation methods, parameter

selection, results, and conclusions, and discuss results with

client.

33.

Prepare copies of IBM compatible data tapes or discs in LIS or

LAS format containing raw data and results.

34.

Provide copies of results to other Phases as required through

the duration of the project.

STEP

10: Check the Petrophysical Results

STEP

10: Check the Petrophysical Results

Quality control of log analysis results derived from visual observations,

chart book methods, programmable calculators, or sophisticated

computer programs, require careful consideration of many factors,

such as:

1.

Sample description, including hydrocarbon shows, porosity indications,

fractures, lithology, and gas kicks.

2.

Hole mechanics, including size, shape, roughness, solution, caving,

casing, and mud type, weight and salinity.

3.

Drill stem test results, including recovery amount and type, flowing

pressures, formation pressure, and mechanical details.

4.

Core data, including porosity, permeability, grain density, lithology

description and saturation.

5.

Production data, including fluid type and amounts, and mechanical

details.

6.

Offset data, including log values, interpretation parameters,

results, and of course, all the above mentioned items on the offset

wells.

7.

The assumptions you made concerning interpretation parameters

and analysis methods.

in

a good analysis, all these factors should corroborate each other.

If they do not, you are missing something or some of your data

is WRONG.

Do

not believe every core, DST, or perf test. They may not be from

the zone they are supposed to be evaluating.

Many

cores range from one to fifteen meters off depth compared to logs.

Since this can usually be identified by the core gamma ray log

or the shape of the porosity distribution, it can easily be cured. Many

cores range from one to fifteen meters off depth compared to logs.

Since this can usually be identified by the core gamma ray log

or the shape of the porosity distribution, it can easily be cured.

However,

DST data does not have any method of correlation, and we must

presume the same frequency and amount of depth adjustment as core

data is needed. Therefore DST's are often off depth compared to

logs.

Perf

tests can be located correctly, because there is usually a correlation

log, but they may produce from elsewhere in the hole due to mechanical

problems, such as channels in the cement, holes in the casing,

tubing or liners, or bad bottom plugs.

Many

cased hole logs may be run to confirm or discount mechanical completion

problems.

A

usual requirement of a log analysis is that it matches core data.

Do not be overly concerned about this, but a reasonable match

is usually possible and expected. The amount of the depth error

may not be clearly discernable by observation of the porosity

curve. The core gamma would be needed to find the correct adjustment.

Variation of one or two percent porosity is common and acceptable,

with the core usually being high. In unconsolidated sands, the

core can be 5 - 10% porosity too high.

A

second requirement is that hydrocarbons be shown on the analysis

over the interval that tested hydrocarbon, and that water be shown

where the well produced water. This is not easy - and many zones

will show water or hydrocarbons where the DST or perf test does

not, especially in shaly sands. Many water tests are really producing

mud filtrate, so take care to distinguish this possibility.

A

good analysis is one that can be reconciled with the facts, without

involving mystical powers or miracles. Adjustments of analysis

parameters are generally needed if agreement is very poor.

Some

zones just do not look good on logs, yet produce prolific quantities

of oil or gas, such as the Viking in Central Alberta or the Austin

Chalk in the Gulf Coast of the USA.

Residual

hydrocarbon, bitumen, or pyrobitumen and heavy oil can cause many

zones to be apparently attractive on logs yet produce water, filtrate,

or nothing on drill stem tests. Try to identify this potential

problem from sample or core description or by moved hydrocarbon

analysis. A similar problem occurs in tight gas sands, where the

zone truly can produce gas, but the DST recovers mud filtrate

or formation water, but little gas.

The

most common error of all is accepting density log data in rough

or large hole - do not be fooled by this. Use the sonic or the

neutron log corrected for shale to see how valid the density log

data might be. DO NOT USE THE DENSITY LOG IF IT IS INCORRECT!!!

Experience

and common sense are the best quality control. Just because it’s

your play, do not make it look too good just because one log can

be used to document your case (and three others contradict it).

Whether

you do an analysis for yourself, your company, or for hire, the

following proviso should be understood by all parties involved:

DISCLAIMER |

| |

GENERAL

TERMS AND CONDITIONS |

| |

Any

interpretation of logs (whether made directly from

logs or by electronic data processing from actual

or digitized log data or electronically transmitted

log data or otherwise) or any recommendation based

on such interpretations are opinions based upon

inferences from electrical or other measurements

and empirical factors and assumptions, which inferences

are not necessarily infallible, and with respect

to which log analysts may differ. Accordingly, we

do not warrant the accuracy or correctness of any

such interpretation or recommendation. Under no

circumstances should any such interpretation or

recommendation be relied upon as the sole basis

for any production decision. We do not guarantee

results. We make no warranties either express or

implied. Under no circumstances shall we be liable

for consequential damages. |

|

Keep

in mind that most service companies use a clause similar to this

one and you should understand the implications of it before you

start any logging operation at a wellsite.

|